A large-scale aspheric topography detection method based on a complex beam angle sensor

An angle sensor and detection method technology, which is applied in the field of optical detection, can solve the problems of low measurement accuracy of the Moire deviation measurement method, and achieve the effects of satisfying measurement accuracy and anti-interference performance, strong anti-interference performance, and simple optical path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Such as Figure 3 to Figure 9 As shown, this embodiment discloses a method for detecting the shape of a large aspheric surface based on a complex beam angle sensor. The method mainly includes the following specific steps:

[0059] Step S1: Place a large aspheric workpiece on a tilting table for measurement, and eliminate measurement errors from both hardware and software.

[0060] Specifically, the hardware aspect in the step S1 refers to fine-tuning and aligning the mechanical and optical systems of the complex beam angle sensor by using two XY stages and a tilting stage, so as to eliminate errors.

[0061] Specifically, the software aspect in the step S1 refers to eliminating errors by means of measurement transfer, and the measurement transfer refers to processing by Fourier transform formulas.

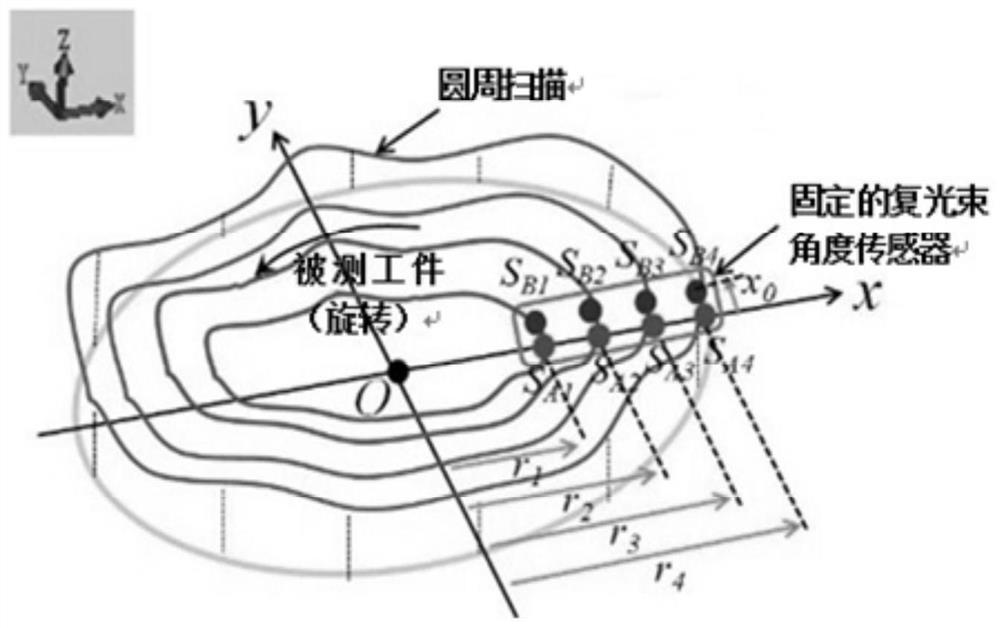

[0062] Step S2: Measurement of angle difference: use a Fourier transform algorithm to perform a circular scan on the large aspheric surface.

[0063] Specifically, the ste...

Embodiment 2

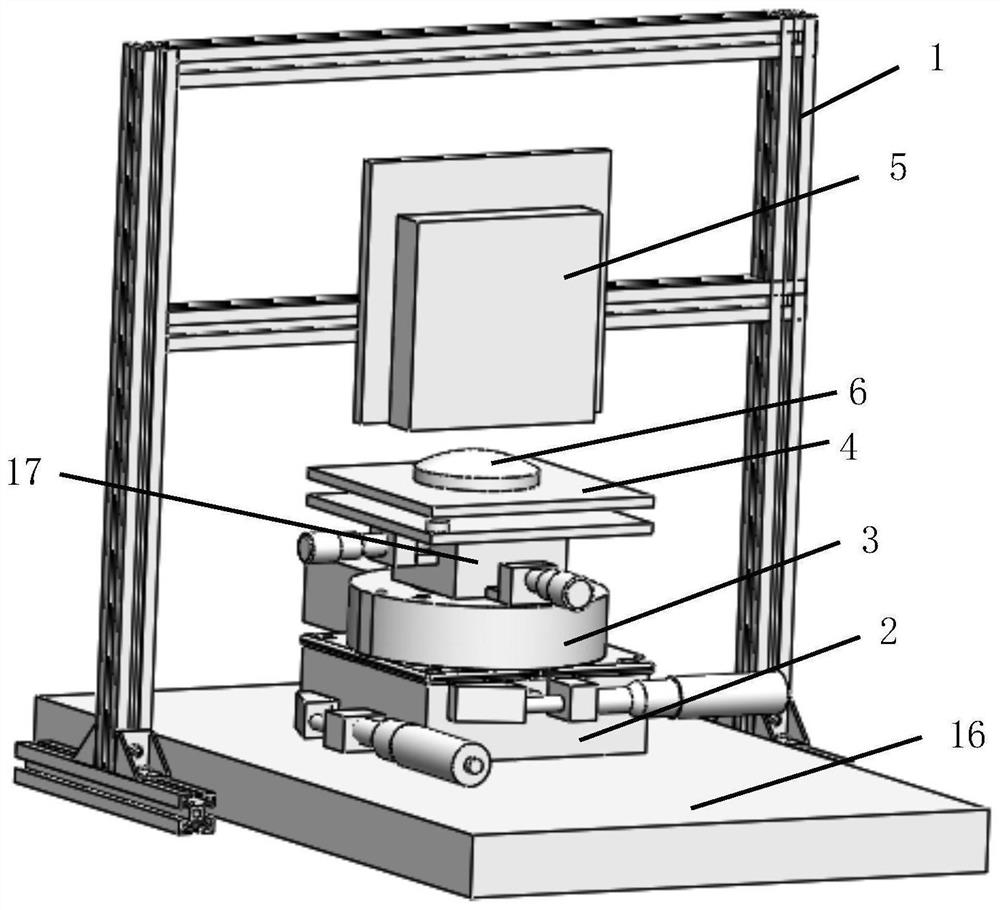

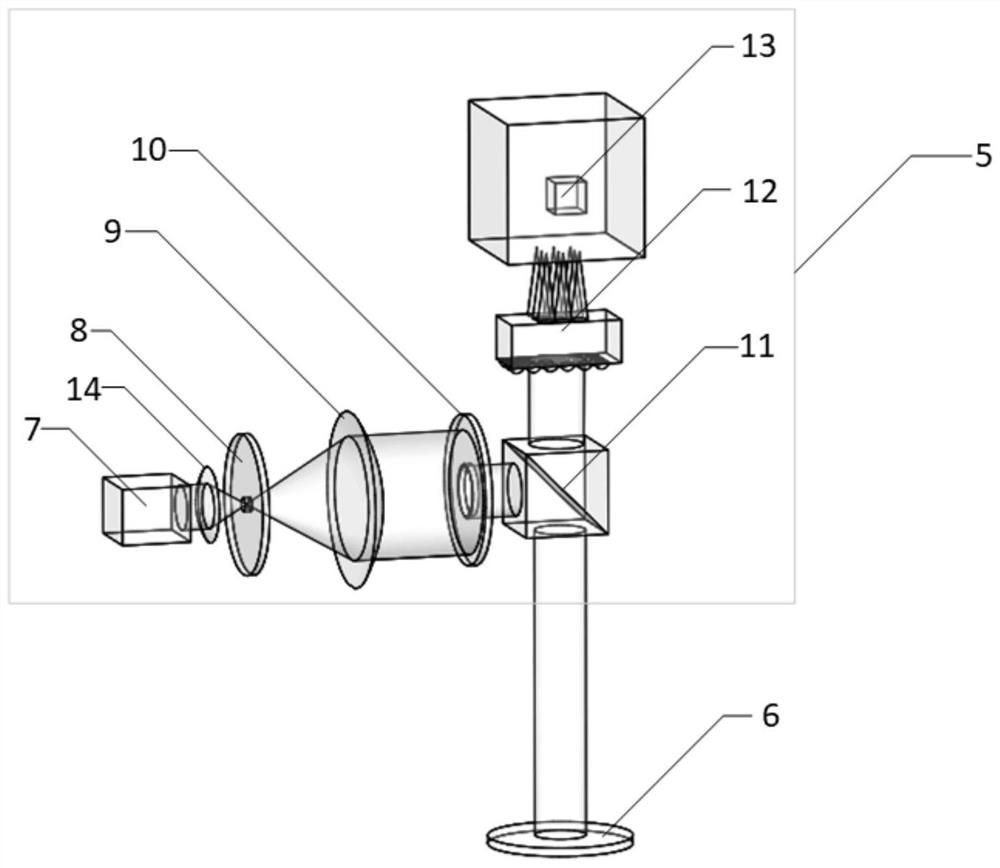

[0083] Such as figure 1 and figure 2 As shown, this embodiment discloses a flatness three-dimensional shape detection device based on complex beam angle adaptive optics, which mainly includes a bearing platform 16, a bracket 1, a first XY platform 2, a second XY platform 17, and a rotating platform 3 , a tilt table 4, and a complex beam angle sensor 5.

[0084] Specifically, the bearing platform 16 is horizontally and fixedly arranged. Both ends of the bracket 1 are clamped on both sides of the bearing platform 16 and are fixedly connected with the bearing platform 16 . The first XY platform 2 is installed on the supporting platform 16 and is fixedly connected with the supporting platform 16 . The rotary table 3 is installed on the first XY platform 2 , and its position is adjusted by the first XY platform 2 . The second XY platform 17 is installed on the turntable 3 and is driven to rotate by the turntable 3 . The tilt table 4 is arranged on the second XY platform 17 , ...

Embodiment 3

[0090] This embodiment discloses a measurement example of using a complex beam angle sensor to simulate a large aspheric surface, as follows:

[0091] In order to evaluate the method of measuring the surface profile of a large aspheric surface by a complex beam angle sensor, specifically, the measured large aspheric workpiece used in this example is a plano-convex prism, and a numerical simulation is carried out for the experiment. Table 1 lists the simulation conditions. Assuming that the curvature radius R of the plano-convex prism is 519mm, the measurement radius R is between 2mm and 4mm, and the CMOS tracks the position of the 5×5 focal point. The pitch of the microlenses is 0.5 mm.

[0092] Table 1 Simulation conditions

[0093]

[0094] Such as Figure 7 , showing a point trajectory similar to the pre-experimental condition, at Figure 8 , the horizontal axis in the figure is the rotation angle, and the vertical axis represents the angle data and angle difference d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com