Cosmetic freeze-dried powder and production process thereof

A production process and technology of freeze-dried powder, which is applied in the field of freeze-dried powder for beauty and production technology, can solve the problems of low storage temperature and easy deterioration, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

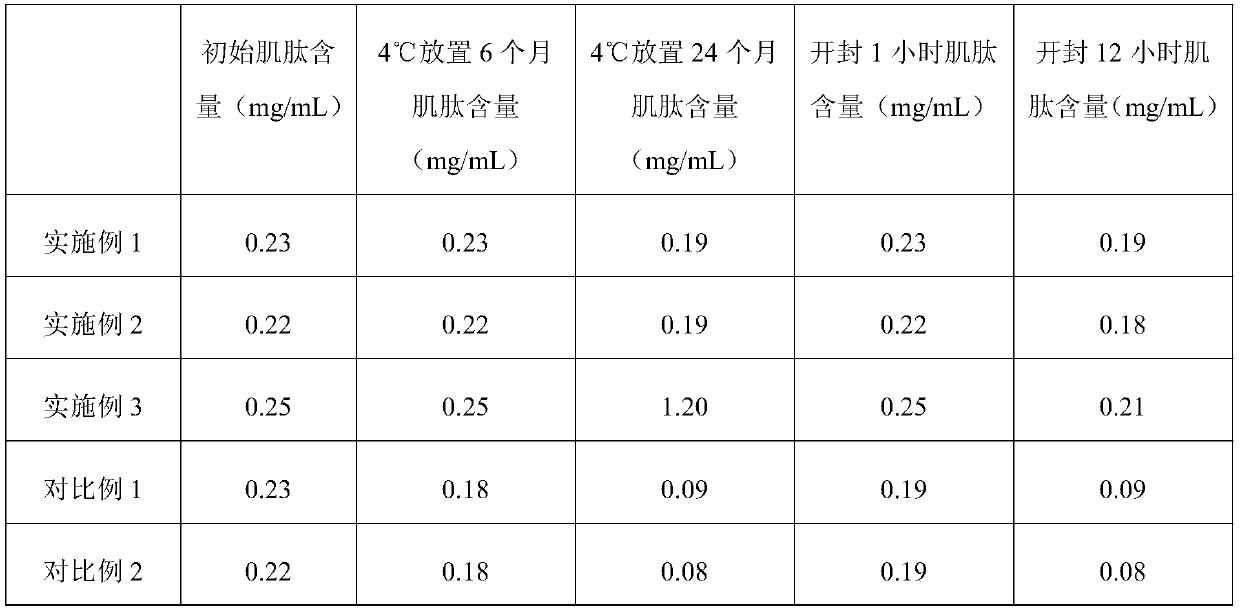

Examples

Embodiment 1

[0031]A production process of freeze-dried powder for cosmetic use. Firstly, active peptides and sialic acid are added to the mixed extract of fresh corn-cactus, mixed evenly, and freeze-dried for the first time to obtain an intermediate product, and then spray pre-cooled powder on the surface of the intermediate product. Cocoa bean-white fungus mixed fermentation liquid, freeze-dried for the second time, and packaged to obtain the described freeze-dried powder for cosmetic use; in parts by weight, the active peptide is 1 part of carnosine and 0.5 part of acetyl tetrapeptide -5. A combination of 0.2 part of skipjack elastin peptide and 0.02 part of nisin.

[0032] The mass ratio of active peptide, sialic acid, fresh corn-cactus mixed extract, cocoa bean-white fungus mixed fermentation liquid is 1:0.4:6:10.

[0033] The preparation method of the fresh corn-cactus mixed extract is as follows: in parts by weight, first add 1 part of fresh corn kernels to 5 parts of water for inje...

Embodiment 2

[0041] A production process of freeze-dried powder for cosmetic use. Firstly, active peptides and sialic acid are added to the mixed extract of fresh corn-cactus, mixed evenly, and freeze-dried for the first time to obtain an intermediate product, and then spray pre-cooled powder on the surface of the intermediate product. Cocoa bean-white fungus mixed fermentation broth, freeze-dried for the second time, and packaged to obtain the described freeze-dried powder for cosmetic use; in parts by weight, the active peptide is 1 part of carnosine and 0.8 part of acetyl tetrapeptide -5. A combination of 0.1 part of skipjack elastin peptide and 0.05 part of nisin.

[0042] The mass ratio of active peptide, sialic acid, fresh corn-cactus mixed extract, cocoa bean-white fungus mixed fermentation liquid is 1:0.2:8:8.

[0043] The preparation method of the fresh corn-cactus mixed extract is as follows: in parts by weight, first add 1 part of fresh corn kernels to 8 parts of water for injec...

Embodiment 3

[0051] A production process of freeze-dried powder for cosmetic use. Firstly, active peptides and sialic acid are added to the mixed extract of fresh corn-cactus, mixed evenly, and freeze-dried for the first time to obtain an intermediate product, and then spray pre-cooled powder on the surface of the intermediate product. Cocoa bean-white fungus mixed fermentation broth, freeze-dried for the second time, and packaged to obtain the described freeze-dried powder for cosmetic use; in parts by weight, the active peptide is 1 part of carnosine and 0.6 part of acetyl tetrapeptide -5. A combination of 0.15 parts of bonito elastin peptide and 0.04 parts of nisin.

[0052] The mass ratio of active peptide, sialic acid, fresh corn-cactus mixed extract, cocoa bean-white fungus mixed fermentation liquid is 1:0.3:7:9.

[0053] The preparation method of the fresh corn-cactus mixed extract is as follows: in parts by weight, first add 1 part of fresh corn kernels to 6 parts of water for inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com