Cross beam structure for large-format optical fiber laser cutting machine

A fiber laser and cutting machine technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of reduced cutting precision and high precision requirements, and achieve the effect of fast running speed, high parameters and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

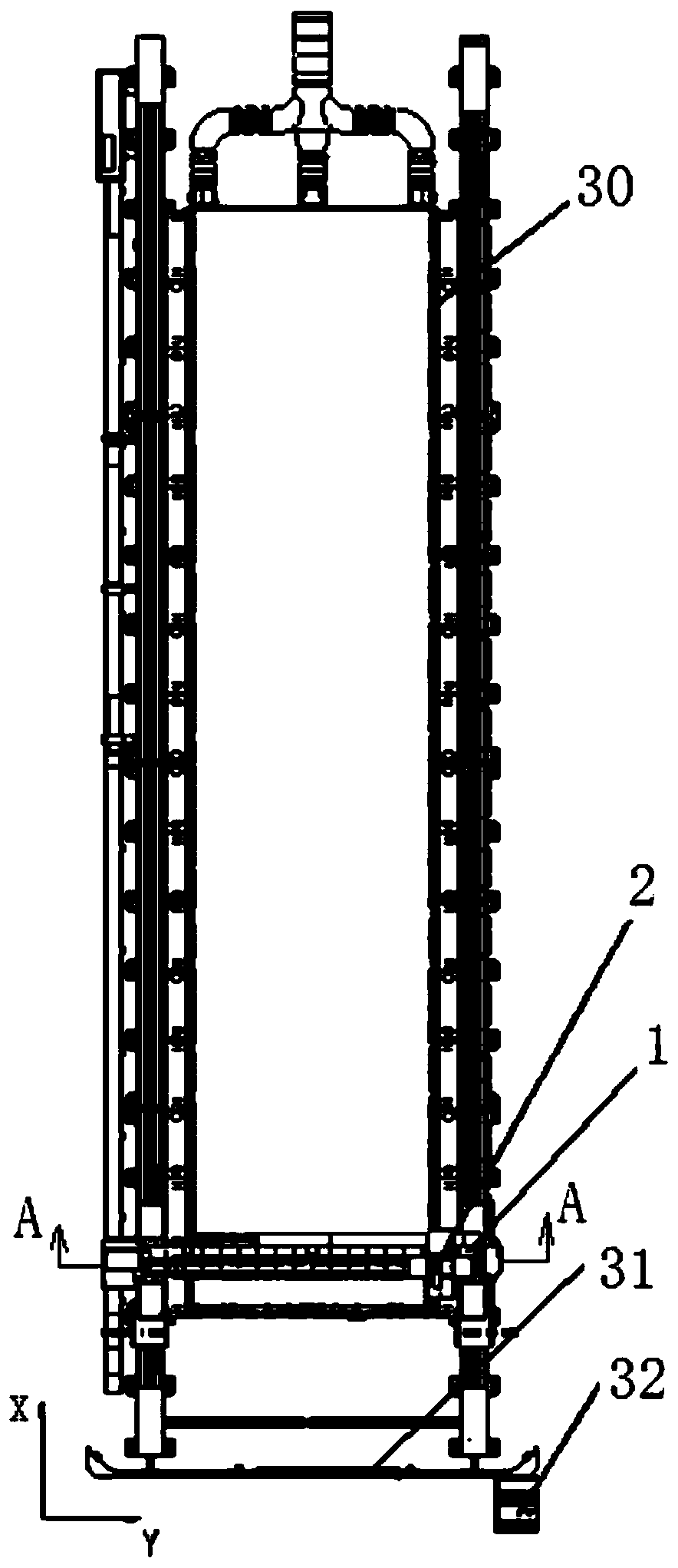

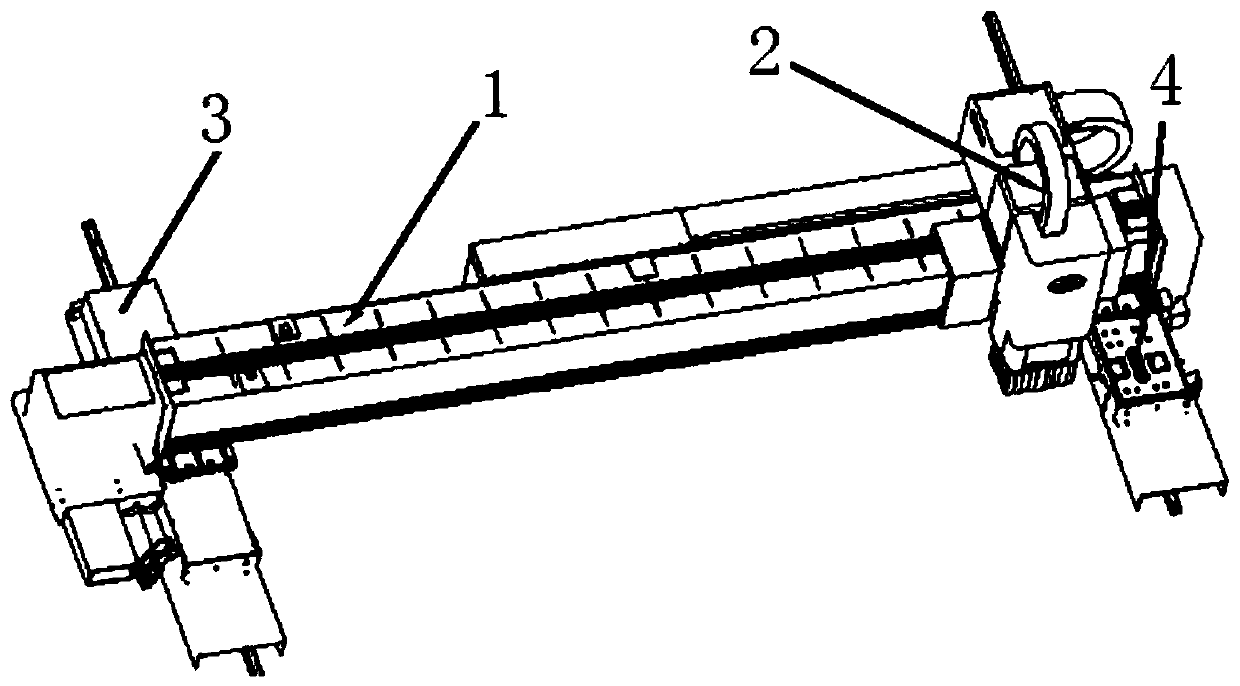

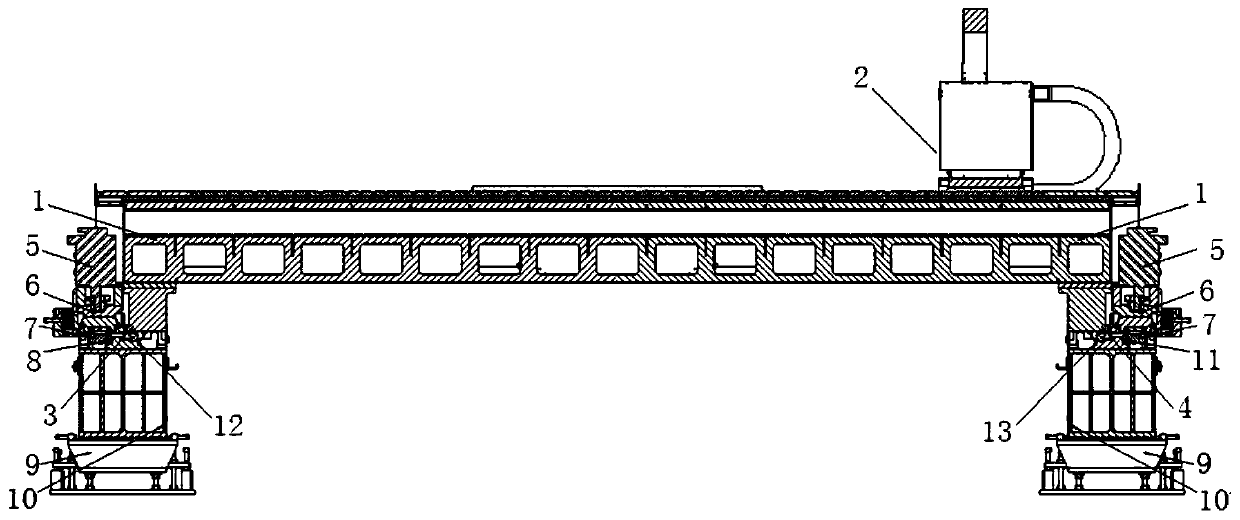

[0028] see Figure 1-8 , a beam structure for a large-format fiber laser cutting machine of the present invention, including a beam and a Z-axis, the Z-axis is installed on the rolling linear guide rail of the beam, and the two ends of the beam are respectively installed on the left beam moving slide and the right beam moving slide On the seat, the left crossbeam moving slide and the right crossbeam moving slide are respectively installed on the rolling linear guide rail of the base, the motor is connected with the reducer, the gear is connected with the reducer, the rack is meshed with the gear, the rack is on the bed, and the bed is fixed On the base, the motor drives the left beam moving slide and the right beam moving slide to move on the rack, and uses the base rolling linear guide to move in the direction of the X axis. The left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com