High-entropy alloy fine grain in-situ additive manufacturing method

A high-entropy alloy and additive manufacturing technology, applied in the field of high-entropy alloys, can solve the problems of micro-crack structure, unevenness, shrinkage, etc., and achieve the effect of promoting phase transformation, uniform composition and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

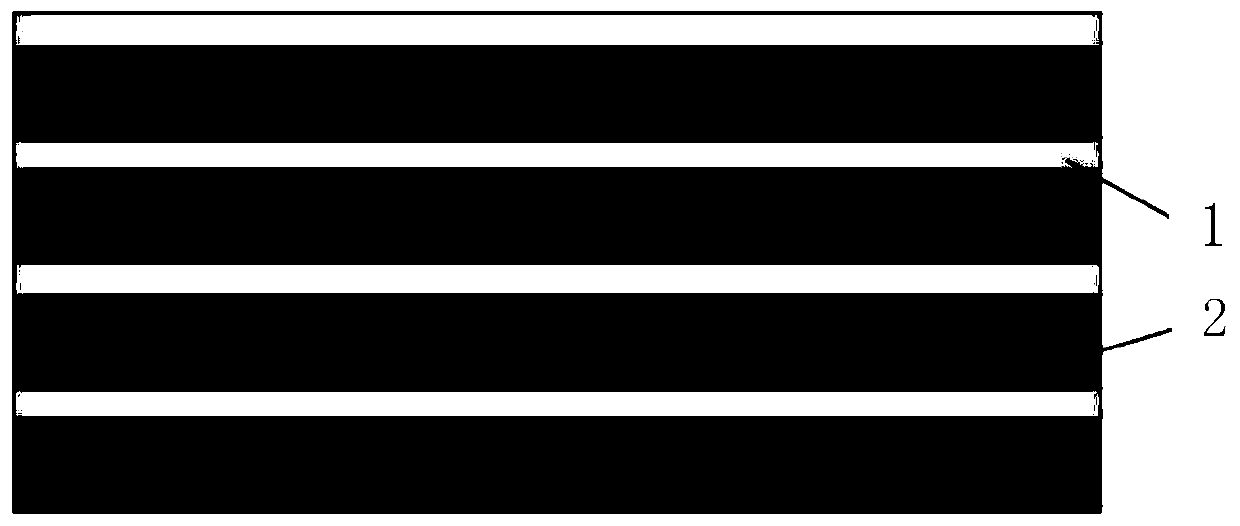

Image

Examples

Embodiment 1

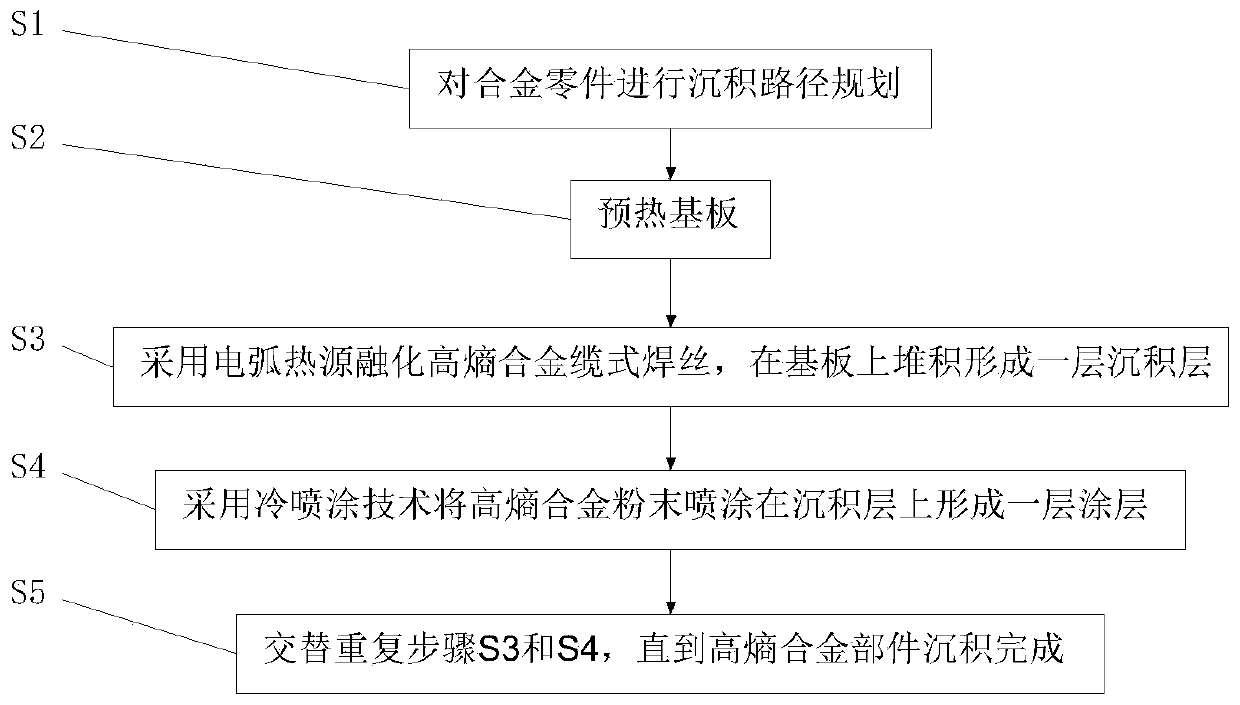

[0035] Embodiment 1: This embodiment discloses a high-entropy alloy fine-grained in-situ additive manufacturing method, including the following steps:

[0036] S1 conducts deposition path planning on alloy parts;

[0037] S2 preheats the substrate;

[0038] S3 uses an arc heat source to melt the high-entropy alloy cable-type welding wire, and accumulates a layer of deposition on the substrate;

[0039] S4 uses cold spray technology to spray high-entropy alloy powder on the deposition layer to form a layer of coating;

[0040] Step S5 alternately repeats steps S3 and S4 until the deposition of the high-entropy alloy component is completed.

[0041] The high-entropy alloy cable welding wire is a simple metal wire or is twisted by alloy wire.

[0042] The high-entropy alloy powder matches the high-entropy alloy cable welding wire.

[0043] The high-entropy alloy fine-grain in-situ additive manufacturing method uses arc additive technology to accumulate a deposition layer on t...

Embodiment 2

[0044] Embodiment 2: This embodiment discloses a high-entropy alloy fine-grained in-situ additive manufacturing method, including the following steps:

[0045] S1 conducts deposition path planning on alloy parts;

[0046] S2 preheats the substrate;

[0047] S3 uses an arc heat source to melt the high-entropy alloy cable-type welding wire, and accumulates a layer of deposition on the substrate;

[0048] S4 uses cold spray technology to spray high-entropy alloy powder on the deposition layer to form a layer of coating;

[0049] Step S5 alternately repeats steps S3 and S4 until the deposition of the high-entropy alloy component is completed.

[0050] The high-entropy alloy cable welding wire is a simple metal wire or is twisted by alloy wire.

[0051] Specifically, the high-entropy alloy powder matches the high-entropy alloy cable welding wire.

[0052] Specifically, the high-entropy alloy cable welding wire and high-entropy alloy powder components include at least one or more ...

Embodiment 3

[0057] Embodiment 3: The present invention also discloses an alloy part, which is made by the following manufacturing method, and the manufacturing method includes the following steps:

[0058] S1 conducts deposition path planning on alloy parts;

[0059] S2 preheats the substrate;

[0060] S3 uses an arc heat source to melt the high-entropy alloy cable-type welding wire, and accumulates a layer of deposition on the substrate;

[0061] S4 uses cold spray technology to spray high-entropy alloy powder on the deposition layer to form a layer of coating;

[0062] Step S5 alternately repeats steps S3 and S4 until the deposition of the high-entropy alloy component is completed.

[0063] The high-entropy alloy cable welding wire is a simple metal wire or is twisted by alloy wire.

[0064] Specifically, the high-entropy alloy powder matches the high-entropy alloy cable welding wire.

[0065] Specifically, the high-entropy alloy cable wire and high-entropy alloy powder components i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com