Flexible electrochromic device and preparation method thereof

An electrochromic and chromogenic technology, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problem of thin film easy to fall off and respond to speed, and achieve the effects of improving electrochromic performance, reducing manufacturing costs, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Preparation of electrochromic gel:

[0025] Add 8.49g of lithium chloride to 20mL of water, stir and dissolve fully to obtain an electrolyte solution; add 3.555g of acrylamide to the above solution, stir until it dissolves, then add 0.0025g of N,N-methylenebisacrylamide, 0.004g Ammonium persulfate and 10μL N,N,N',N'-tetramethyldiethylamine, mixed evenly; finally add 0.02mol / L potassium tungstate, continue to stir for 1~3h to completely dissolve, and obtain the electro-induced Color changing gel prepolymer solution.

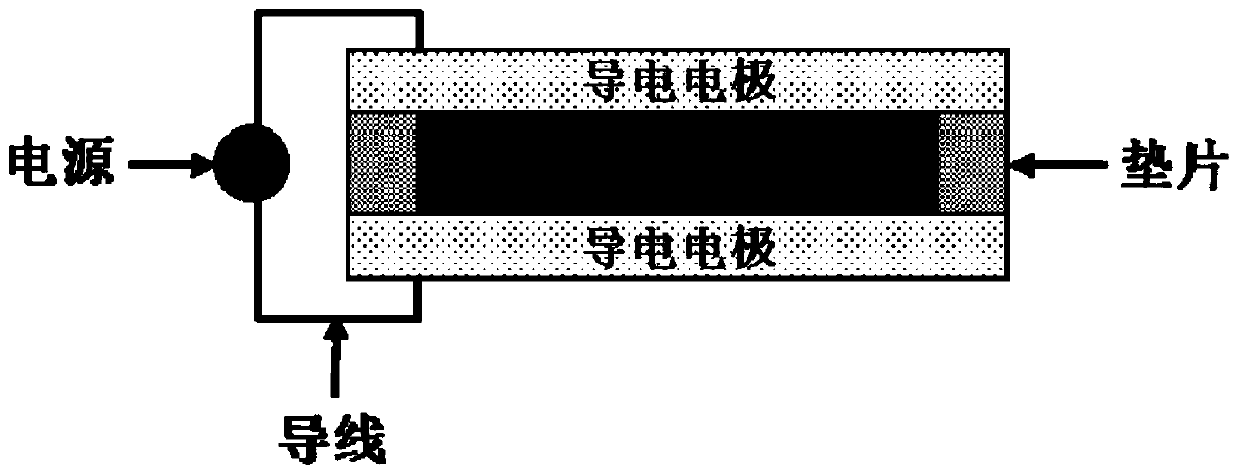

[0026] (2) Preparation of flexible electrochromic devices:

[0027] First, the ITO film conductive electrode was ultrasonically cleaned with deionized water, acetone and isopropanol for 15 minutes respectively, and dried with nitrogen gas for later use; the electrochromic gel prepolymer solution was injected into the space of the silica gel pad clamped on the conductive electrode , heated at 40° C. for 2 hours to obtain an electrochromic gel layer; th...

Embodiment 2

[0029] (1) Preparation of electrochromic gel:

[0030] Add 11.69g of sodium chloride into 20mL of water, stir and dissolve fully to obtain an electrolyte solution; add 3.61g of acrylic acid into the above solution, stir until it dissolves, then add 0.0025g of N,N-methylenebisacrylamide, 0.004g of Ammonium sulfate and 10 μL N,N,N',N'-tetramethyldiethylamine, mix well; finally add 0.02mol / L potassium tungstate, continue to stir for 1~3h to completely dissolve, and obtain electrochromic Gel prepolymer solution.

[0031] (2) Preparation of flexible electrochromic devices:

[0032] First, the FTO film conductive electrode was ultrasonically cleaned with deionized water, acetone and isopropanol for 15 minutes respectively, and dried with nitrogen gas for use; the electrochromic gel prepolymer solution was injected into the space of the silica gel pad clamped on the conductive electrode , heated at 40° C. for 2 hours to obtain an electrochromic gel layer; then take another piece of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com