Novel cable insulation layer repairing machine

An insulating layer and cable technology, which is used in conductor/cable insulation, insulated/armored cable repair equipment, cable/conductor manufacturing, etc., and can solve problems such as difficult to control hot air temperature, unstable hot air process, and uneven hot air temperature. , to achieve low requirements for workers to repair skills and experience, reduce the time required for worker training, and improve the effect that is difficult to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

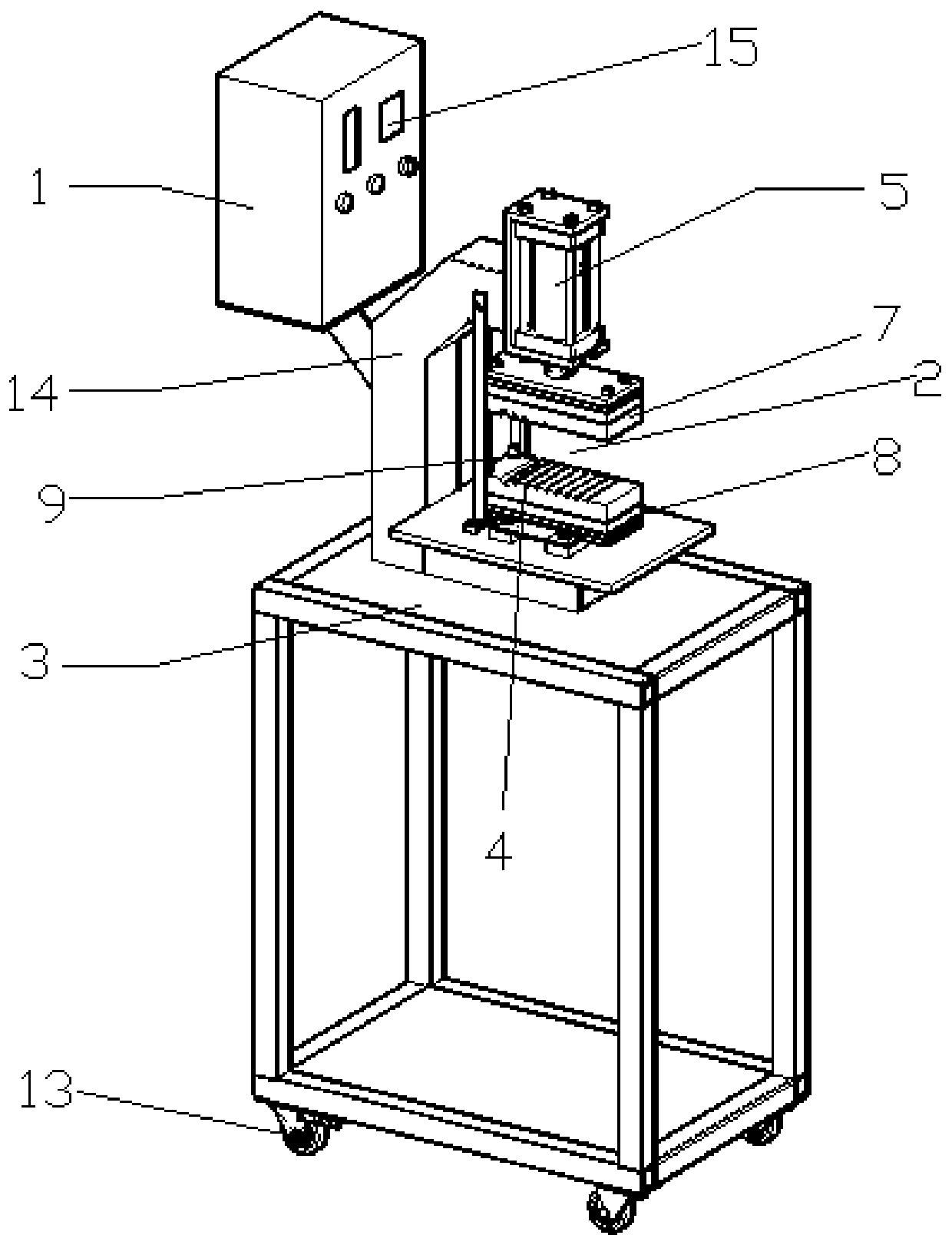

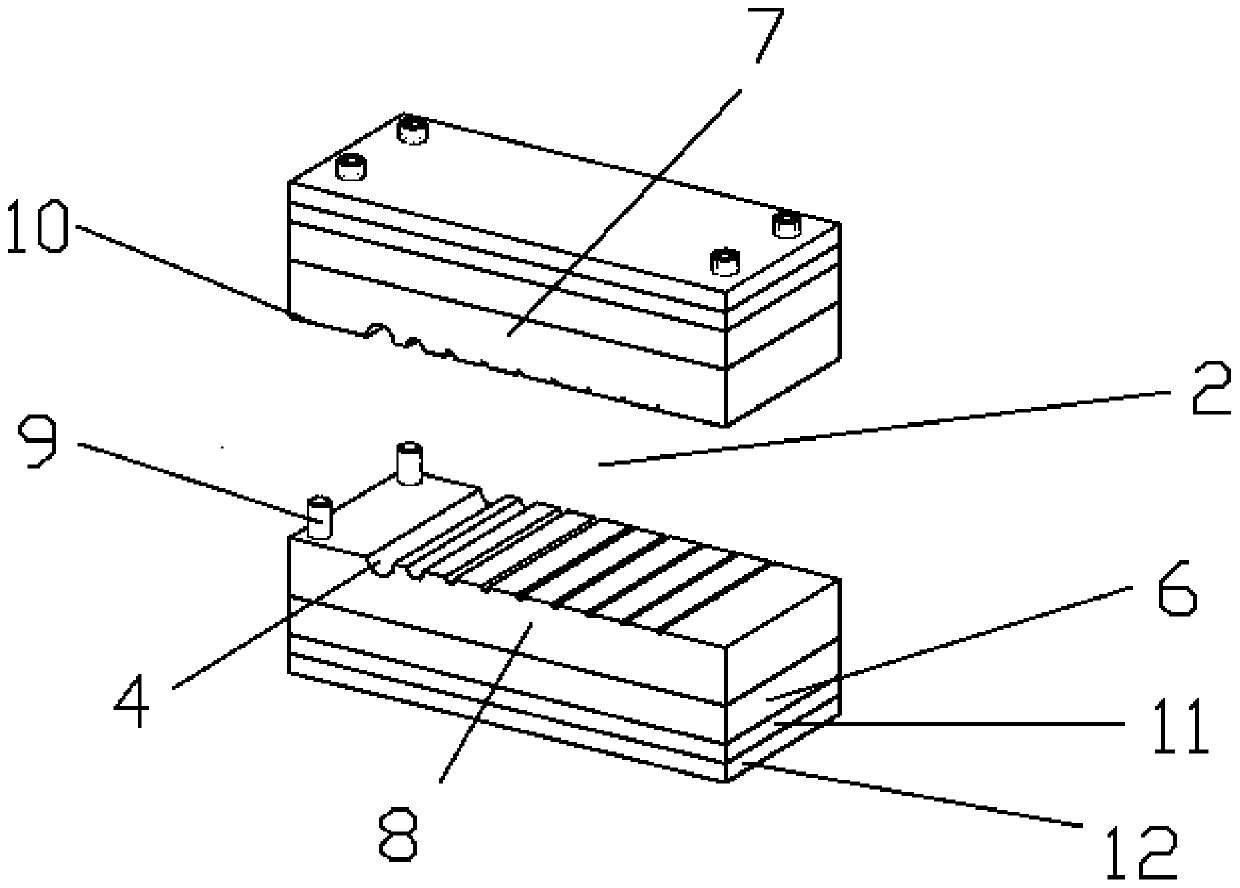

[0020] Attached below figure 1 To attach figure 2 To further illustrate the present invention, a new type of cable insulation repairing machine includes a power supply device 1 for supplying and controlling power, a cable mold 2 for repairing cable insulation, and a working platform 3. The wire The cable mold 2 is provided with a cable supplementary hole 4, and the cable mold 2 is provided with a driving device 5 for driving the opening and closing of the cable mold 2 and exerting pressure on the cable. The heating structure 6 of the cable mold 2 is heated, and the driving device 5 and the heating structure 6 are both electrically connected to the power supply device 1 .

[0021] The cable mold 2 includes an upper mold 7 and a lower mold 8, the upper mold 7 is connected with the driving device 2, the lower mold 8 is fixed on the working platform 3, a supporting plate is set on the working platform 3, and the lower mold 8 By arranging the base to be fixed on the supporting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com