Yoke-free split disc type motor

A disc-type motor and split-flap technology, which is applied in the direction of electromechanical devices, electrical components, mechanical equipment, etc., can solve problems such as the inability to adjust the output direction of the output shaft, cannot meet the needs of use, and the high torque density of the motor is small, reaching the efficiency range High, improve the independence and fault tolerance of each phase, and the effect of high torque density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

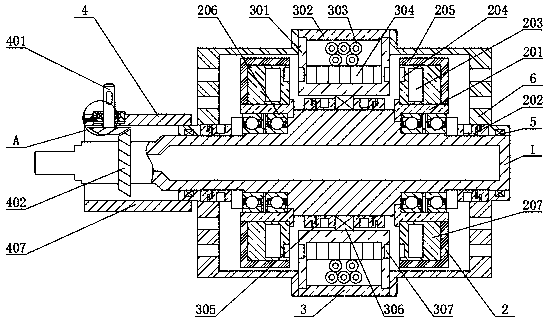

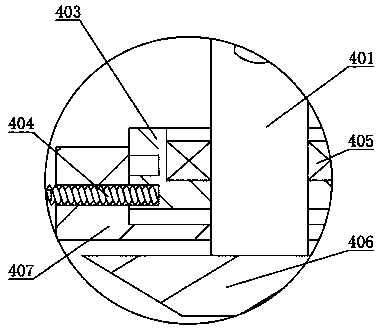

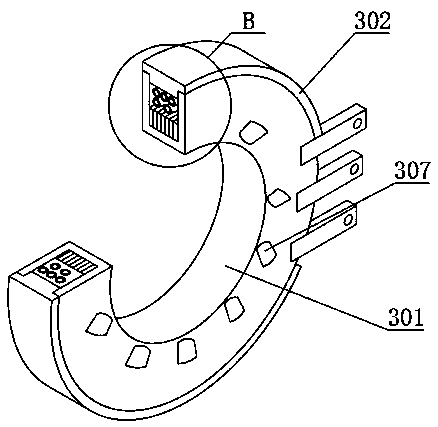

[0025] see Figure 1-6 , the present invention provides a technical solution:

[0026] A yokeless split disc motor, comprising a first output shaft 1, a rotor device 2, a stator device 3, an adjustment device 4, a fourth bearing 5 and a motor housing 6, the outer side of the first output shaft 1 is fixedly connected with a stator In the device 3, the left and right ends of the stator device 3 are respectively provided with a rotor device 2, and the rotor device 2 is rotationally connected with the first output shaft 1, and the outer side of the first output shaft 1 is fixedly connected with a fourth bearing 5, and the fourth bearing 5 The outer side is fixedly connected with the motor casing 6, and the motor casing 6 is fixedly connected with the stator device 3, and the rotor device 2 includes a shaft sleeve 201, a first locking nut 202, a rotor yoke 203, a permanent magnet 204, a rotor bracket 205, a first Bearing 206 and rotor support plate 207, the outer side of the first...

Embodiment 2

[0029] see Figure 1-6 , the present invention provides a technical solution:

[0030] A yokeless split disc motor, comprising a first output shaft 1, a rotor device 2, a stator device 3, an adjustment device 4, a fourth bearing 5 and a motor housing 6, the outer side of the first output shaft 1 is fixedly connected with a stator In the device 3, the left and right ends of the stator device 3 are respectively provided with a rotor device 2, and the rotor device 2 is rotationally connected with the first output shaft 1, and the outer side of the first output shaft 1 is fixedly connected with a fourth bearing 5, and the fourth bearing 5 The outer side is fixedly connected with the motor casing 6, and the motor casing 6 is fixedly connected with the stator device 3, and the rotor device 2 includes a shaft sleeve 201, a first locking nut 202, a rotor yoke 203, a permanent magnet 204, a rotor bracket 205, a first Bearing 206 and rotor support plate 207, the outer side of the first o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com