Improvements to drying textiles

A drying and drying machine technology, applied in textiles and papermaking, non-progressive dryers, drying, etc., can solve problems such as wasting time and energy, and low efficiency of clothes dryers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

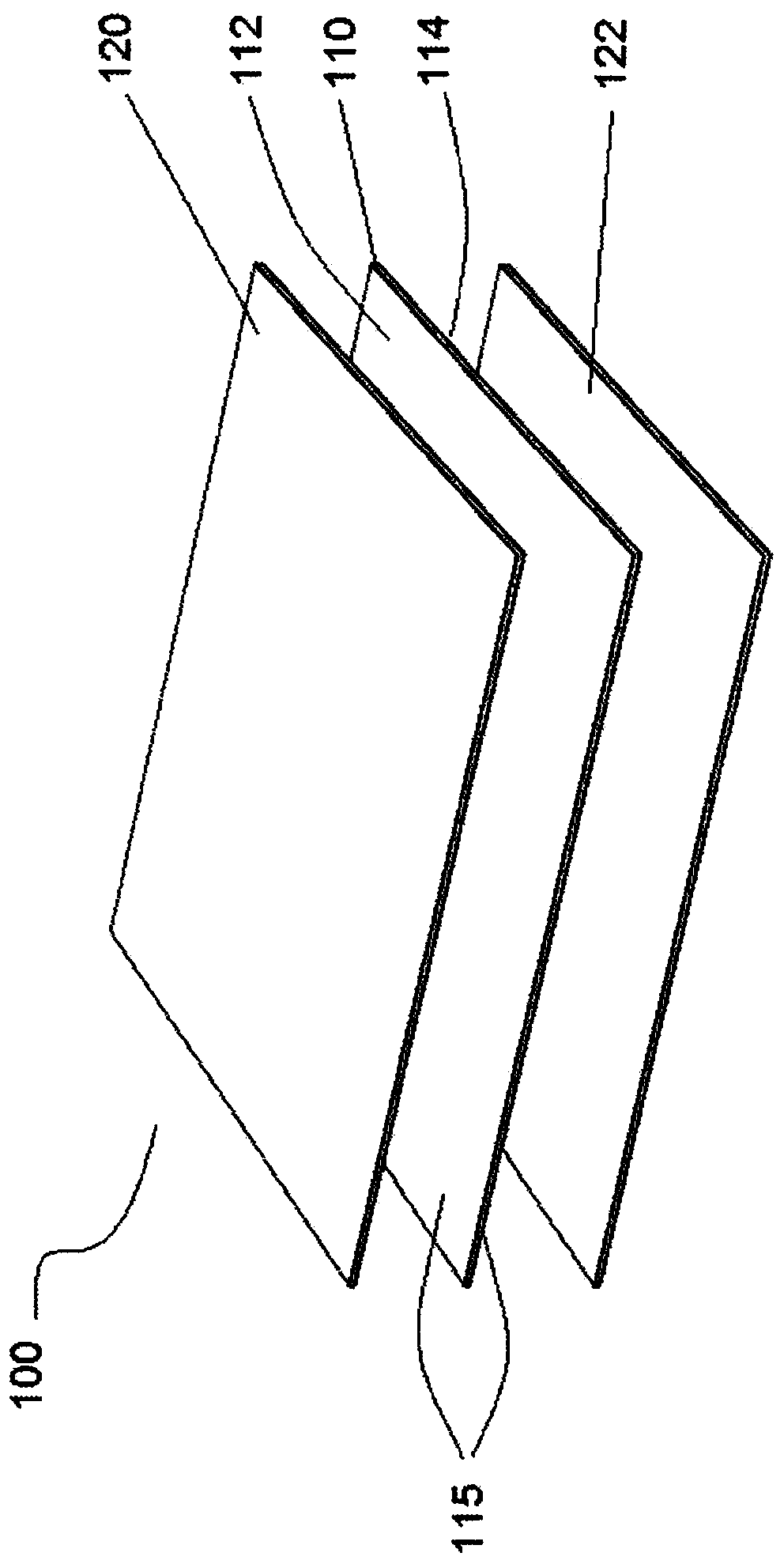

[0044] Such as figure 1 As shown, a device 100 according to some embodiments of the present invention includes a non-woven fabric carrier layer or substrate 110 having a first surface 112 and an opposing second surface 114 . Hot melt adhesive 115 is applied to both surfaces 112 , 114 . A heat reflective layer 120, 122 having a heat reflective outer surface is disposed on each layer of the adhesive 112, thereby providing a layered / laminated and substantially The device 100 is in the form of a sheet. Alternatively, the adhesive and heat reflective layer may be applied to only one side of the carrier layer 110, and optionally the other side may also include an adhesive layer for sealing and waterproofing the carrier layer, in particular If the carrier layer is made of absorbent material.

[0045] It will be understood that the term "layer" as used for heat reflective layers includes coatings, films, and the like.

[0046] The carrier layer 110 is suitably a non-woven fabric m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com