Ascorbyl palmitate based baking oil and preparation method thereof

An ascorbyl palmitate, baking technology, applied in the directions of edible oil/fat, baked goods with modified ingredients, food science, etc., can solve the problems of oil quality risk, complicated preparation steps of gelling agent, etc., to improve nutritional properties, Good performance, low saturated fatty acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

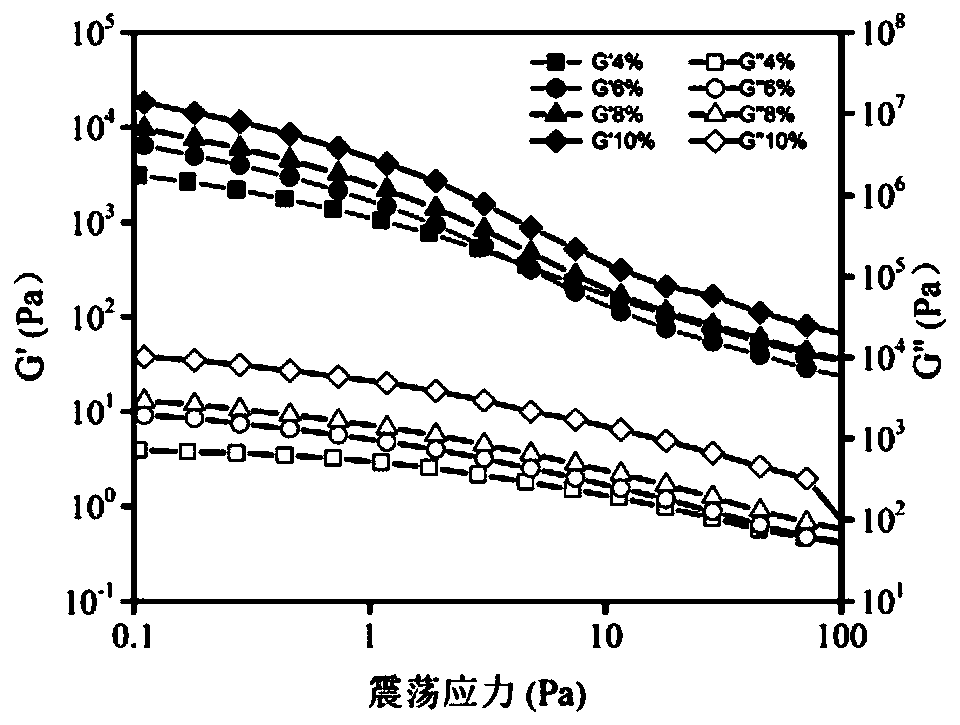

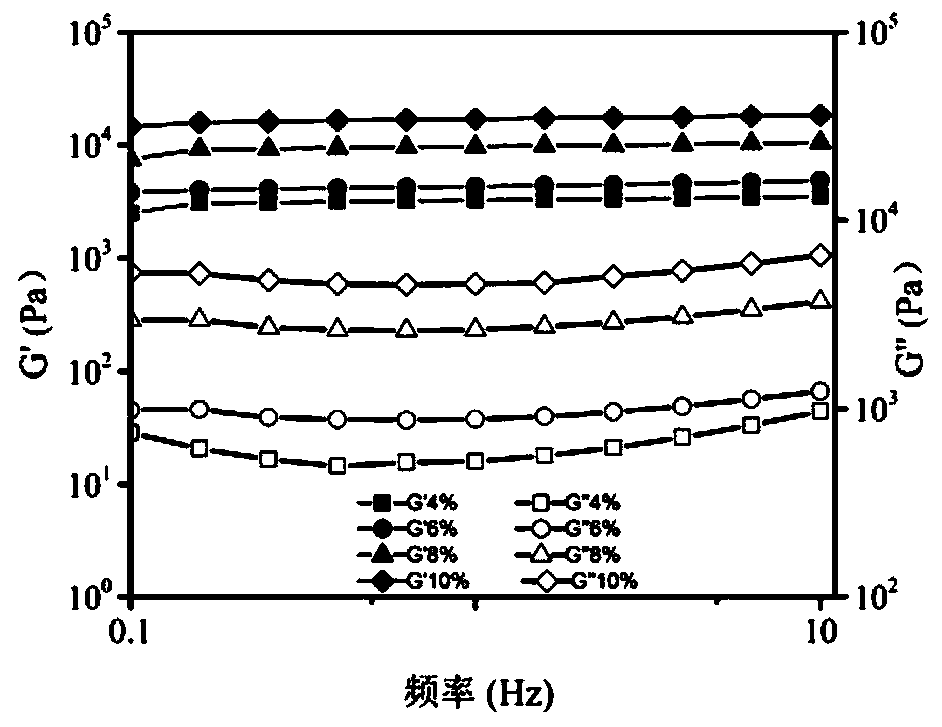

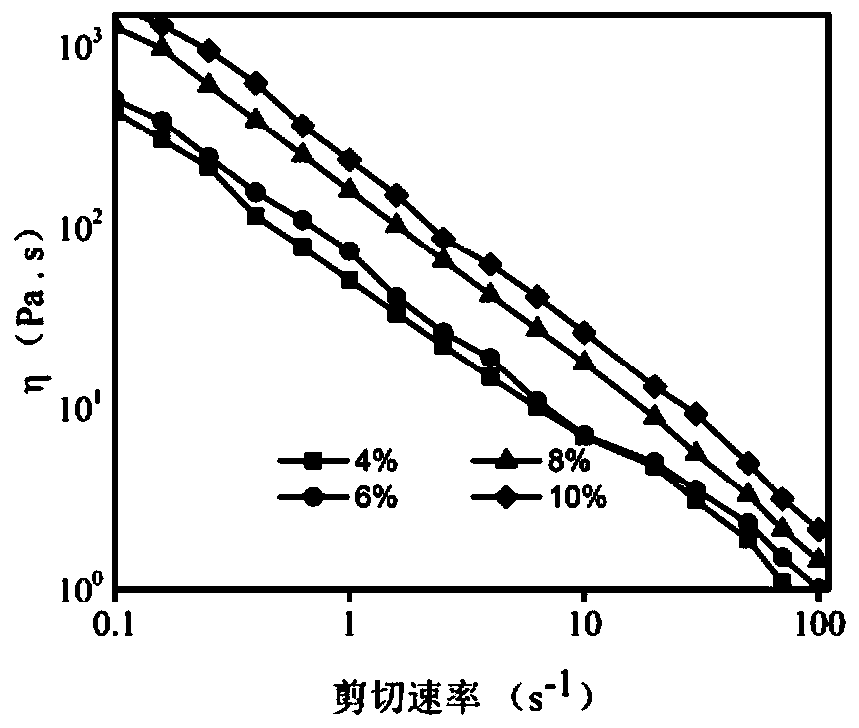

[0034] (1) Preparation of L-ascorbyl palmitate ethanol solution: fully dissolve L-ascorbyl palmitate accounting for 4% of the mass fraction of the final baked oil into ethanol according to the solubility of 1 g in 4.5 ml of ethanol;

[0035] (2) Mix the sample: the L-ascorbyl palmitate ethanol solution obtained in step (1) is mixed with sunflower oil for subsequent use;

[0036] (3) Formation of the gel network: the sample mixed solution obtained in step (2) was rotated at 55° C. for 0.5 h to remove ethanol and form a gel oil network at the same time;

[0037](4) Aging: Place the sample obtained in step (3) at 20°C and let it stand for 24 hours to obtain L-ascorbyl palmitate-based baking oil, and place the L-ascorbyl palmitate-based baking oil at 3-5°C Store in the refrigerator.

Embodiment 2

[0039] (1) Preparation of L-ascorbyl palmitate ethanol solution: fully dissolve L-ascorbyl palmitate accounting for 6% of the mass fraction of baked oil into ethanol according to the solubility of 1 g in 4.5 ml of ethanol;

[0040] (2) Mix the sample: the L-ascorbyl palmitate ethanol solution obtained in step (1) is mixed with sunflower oil for subsequent use;

[0041] (3) Formation of the gel network: the sample mixed solution obtained in step (2) was rotated at 55° C. for 0.5 h to remove ethanol and form a gel oil network at the same time;

[0042] (4) Aging: Place the sample obtained in step (3) at 20°C and let it stand for 24 hours to obtain L-ascorbyl palmitate-based baking oil, and place the L-ascorbyl palmitate-based baking oil at 3-5°C Store in the refrigerator.

Embodiment 3

[0044] (1) Preparation of L-ascorbyl palmitate ethanol solution: fully dissolve L-ascorbyl palmitate accounting for 8% of the mass fraction of baked oil into ethanol according to the solubility of 1 g in 4.5 ml of ethanol;

[0045] (2) Mix the sample: the L-ascorbyl palmitate ethanol solution obtained in step (1) is mixed with sunflower oil for subsequent use;

[0046] (3) Formation of the gel network: the sample mixed solution obtained in step (2) was rotated at 55° C. for 0.5 h to remove ethanol and form a gel oil network at the same time;

[0047] (4) Aging: Place the sample obtained in step (3) at 20°C and let it stand for 24 hours to obtain L-ascorbyl palmitate-based baking oil, and place the L-ascorbyl palmitate-based baking oil at 3-5°C Store in the refrigerator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com