Low saturation peanut oil product maintaining flavor of peanut oil

A peanut oil and aroma technology, applied in food preparation, edible oil/fat, food science, etc., can solve problems such as technical difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

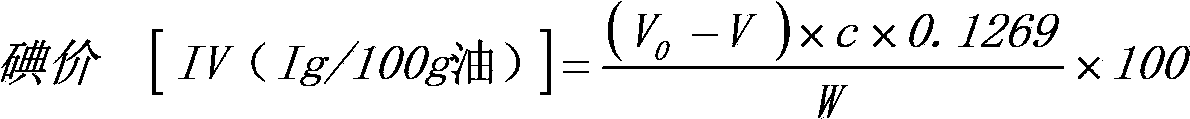

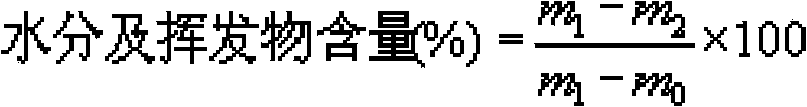

Method used

Image

Examples

preparation example Construction

[0114] The preparation method provided by the present invention can be used to prepare peanut oil or products containing peanut oil.

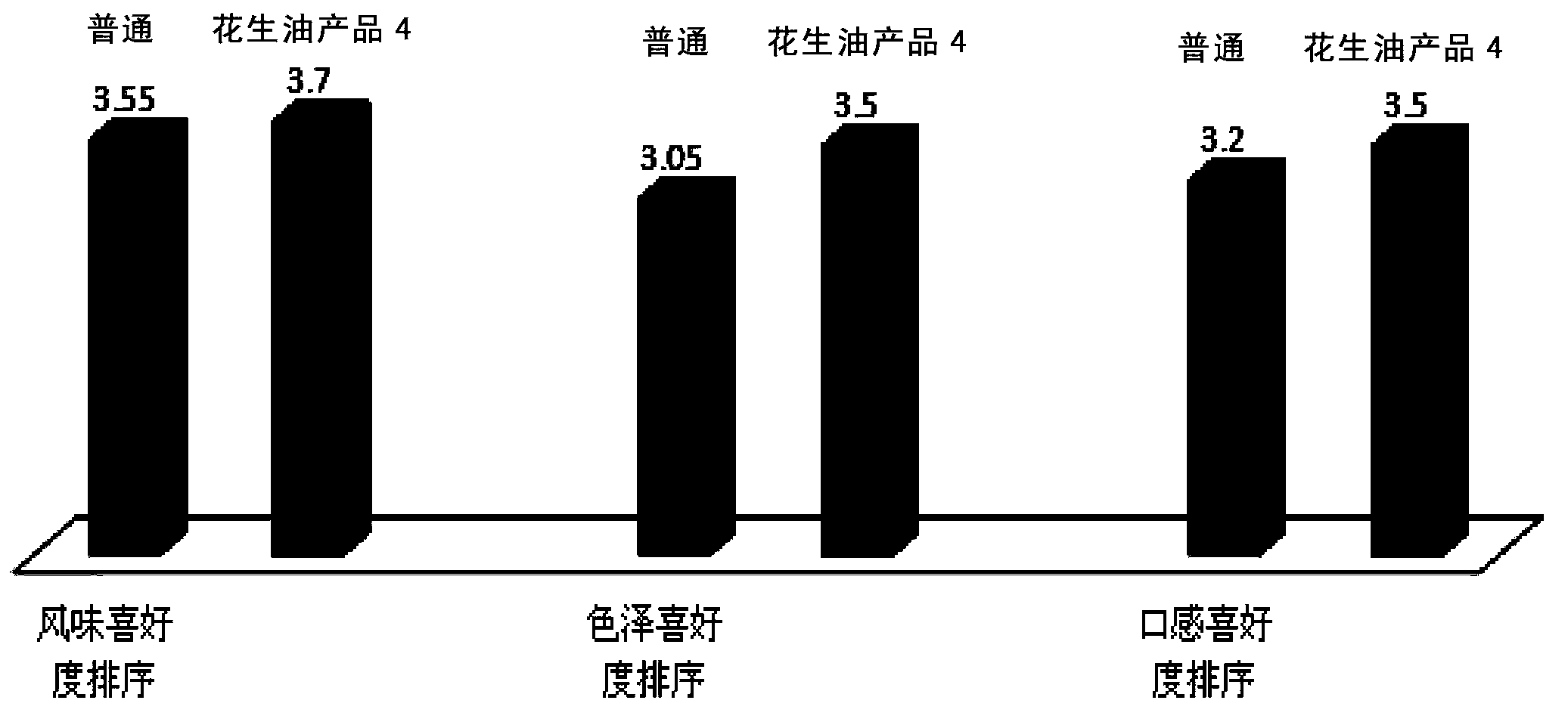

[0115] The peanut oil product of the present invention retains the good flavor of peanut oil, and one or more of the above-mentioned properties is superior to ordinary peanut oil. It can be applied to many aspects like ordinary peanut oil, including: food preparation or As an additive in food preparation. For example, it is used in the production of stir-frying, oil and fat, and the preparation of foods such as bread, cakes, biscuits, toffee, popcorn, non-dairy creamer, candy, puffed food, etc. Since the peanut oil of the invention has low saturated fatty acid content, the food prepared by using the peanut oil is more beneficial to health.

[0116] The main advantages of the processing method and product of the present invention

[0117] (1) The method of the present invention has simple process, short operation time, high yield, no introduction of ...

Embodiment 1

[0172] Example 1. Preparation of peanut oil product 1

[0173] The raw peanut oil is heated to 15°C, and then passed through a static mixer (the front of the mixer is equipped with a nitrogen inlet with a one-way valve), and a small amount of nitrogen (pressure controlled at 0.3bar) is mixed and homogenized (static mixer). Transported to the crystallization tank, according to the pre-set program, the oil temperature is slowly reduced from 35°C to -2°C, the cooling rate is controlled to 2°C / hour, and the stirring speed is controlled to 15RPM. Then, the crystal is cultivated for 1.5 hours, and the stirring speed is 5RPM during crystal growing. After crystal growing, it is transported to a membrane filter press with accompanying cooling by a screw pump (the accompanying cooling temperature is controlled at 2°C). The filter cloth material is air permeability 100l / dm 2 / min antistatic polyester cloth, filter pressure 1~3bar, get clear liquid oil.

Embodiment 2

[0174] Example 2. Preparation of peanut oil product 2

[0175] Heat the ordinary peanut oil to 37°C, then pass a small amount of nitrogen (pressure controlled at 0.3bar) through a static mixer, mix and homogenize, and then transfer it to the crystallization tank. According to the preset program, the temperature drops from 37°C To -3°C, control the cooling rate to 2.5°C / hour, and control the stirring speed to 14RPM. Then, the crystal is grown for 1 hour, and the stirring speed is 8RPM during the growth of the crystal. After the growth of the crystal, it is transported to the membrane filter press with accompanying cooling by a screw pump for filtration (the temperature of the accompanying cooling is controlled at 0-1℃). The filter cloth material is Antistatic polyester cloth with an air permeability of 120l / dm2 / min and a filtration pressure of 1 to 3 bar to obtain a clear liquid oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com