Emulsion, and processing system and processing method thereof

A technology for processing systems and emulsions, applied in chemical instruments and methods, dissolving, mixers, etc., can solve the problem that random adjustment cannot be performed, the device occupies a large area, and the power mechanism drives the material-carrying support and the collection support to move forward. The bracket pushes the push rods on the corresponding side in turn. The raw material baffle is not in the closed storage box. The storage box collects different raw materials for processing the toner, and the storage box is removed to complete a collection. The power mechanism drives the material transport bracket and the collection bracket to reverse. Movement, the collecting bracket pushes the push rod corresponding to the other side in turn, and the raw material baffle is not closed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

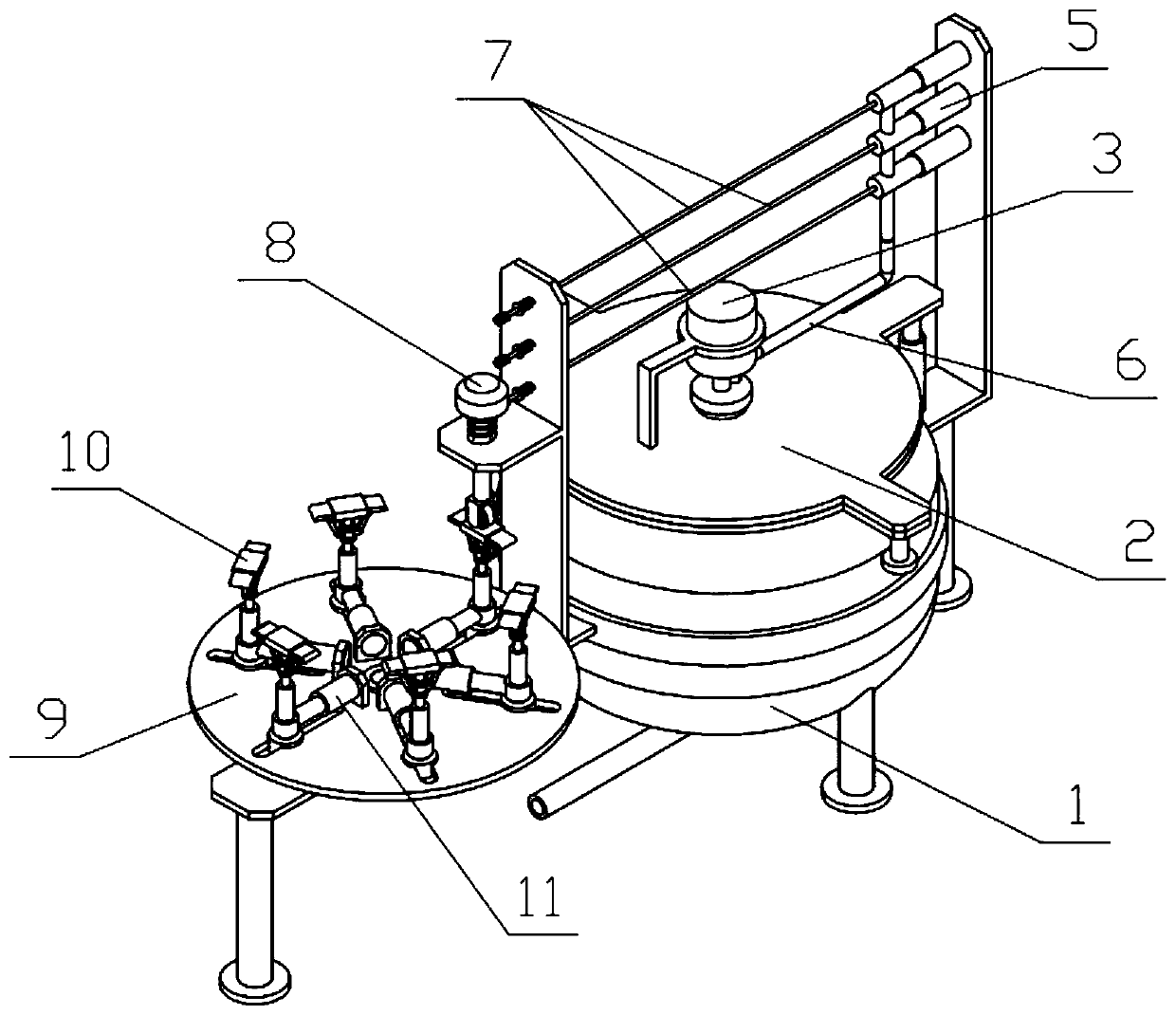

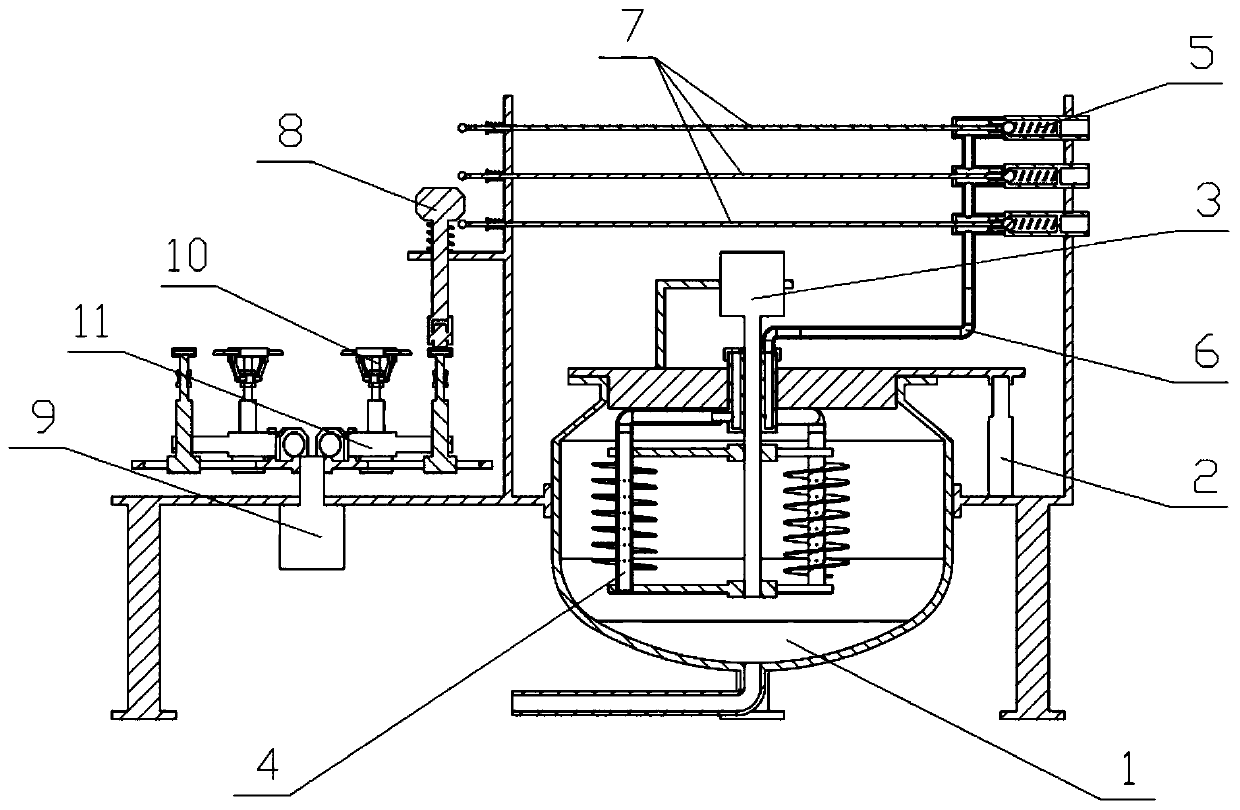

[0040] Combine below Figure 1-12 Describe this embodiment, an emulsion and processing system, including a device bracket 1, a cover mechanism 2, a power mechanism 3, a stirring mechanism 4, an injection pipeline 5, a connecting hose 6, a closing mechanism 7, a height mechanism 8, and a rotation mechanism 9 , a pushing mechanism 10 and a telescopic mechanism III11, the device bracket 1 is provided with a covering mechanism 2, the covering mechanism 2 is fixedly connected with a power mechanism 3, the power mechanism 3 is connected with a stirring mechanism 4, and the stirring mechanism 4 is rotatably connected to On the cover mechanism 2, an inlet pipe 5-1, an outlet pipe 5-2 and a one-way ball 5-3 are arranged on the injection pipe 5, and a one-way ball 5 is arranged between the inlet pipe 5-1 and the outlet pipe 5-2. -3, multiple injection pipelines 5 are provided, and multiple injection pipelines 5 are fixedly connected to the device support 1, and multiple outlet pipelines...

specific Embodiment approach 2

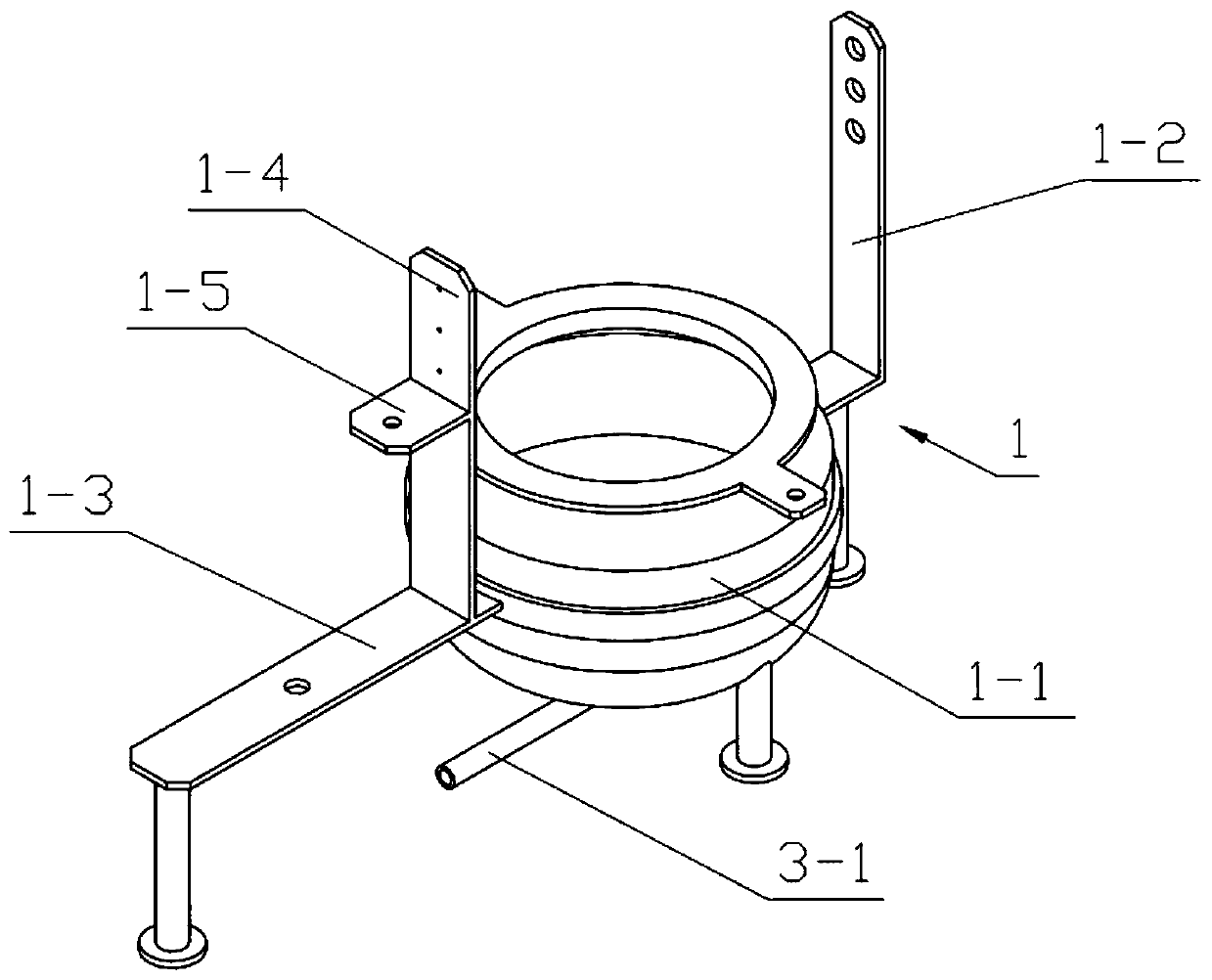

[0042] Combine below Figure 1-12 Describe this embodiment, this embodiment will further explain Embodiment 1, the device bracket 1 includes a mixing kettle 1-1, a support plate I1-2, a support plate II1-3, a support plate III1-4 and a support plate IV1-5 , one side of the mixing kettle 1-1 is fixedly connected with a support plate I1-2, the other side of the mixing kettle 1-1 is fixedly connected with a support plate II1-3, and the support plate II1-3 is fixedly connected with a support plate III1-4 , the support plate Ⅲ1-4 is fixedly connected with the support plate Ⅳ1-5, the lower end of the mixing kettle 1-1 is provided with a discharge pipe, and the discharge pipe is provided with a valve.

specific Embodiment approach 3

[0044] Combine below Figure 1-12 Describe this embodiment, this embodiment will further explain the second embodiment, the cover mechanism 2 includes a cover 2-1 and a telescopic mechanism I2-2, and the cover 2-1 is closed on the mixing kettle 1 -1, the telescopic mechanism I2-2 is fixedly connected to the support plate I1-2, and the telescopic end of the telescopic mechanism I2-2 is fixedly connected to the upper cover 2-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com