Method and device for preparing homogeneous catalyst slurry with controllable concentration

A catalyst slurry and preparation device technology, applied in chemical instruments and methods, mixing methods, transportation and packaging, etc., can solve the problems of membrane electrode performance and consistency not guaranteed, catalyst oxidation, catalyst loading uncontrollable, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

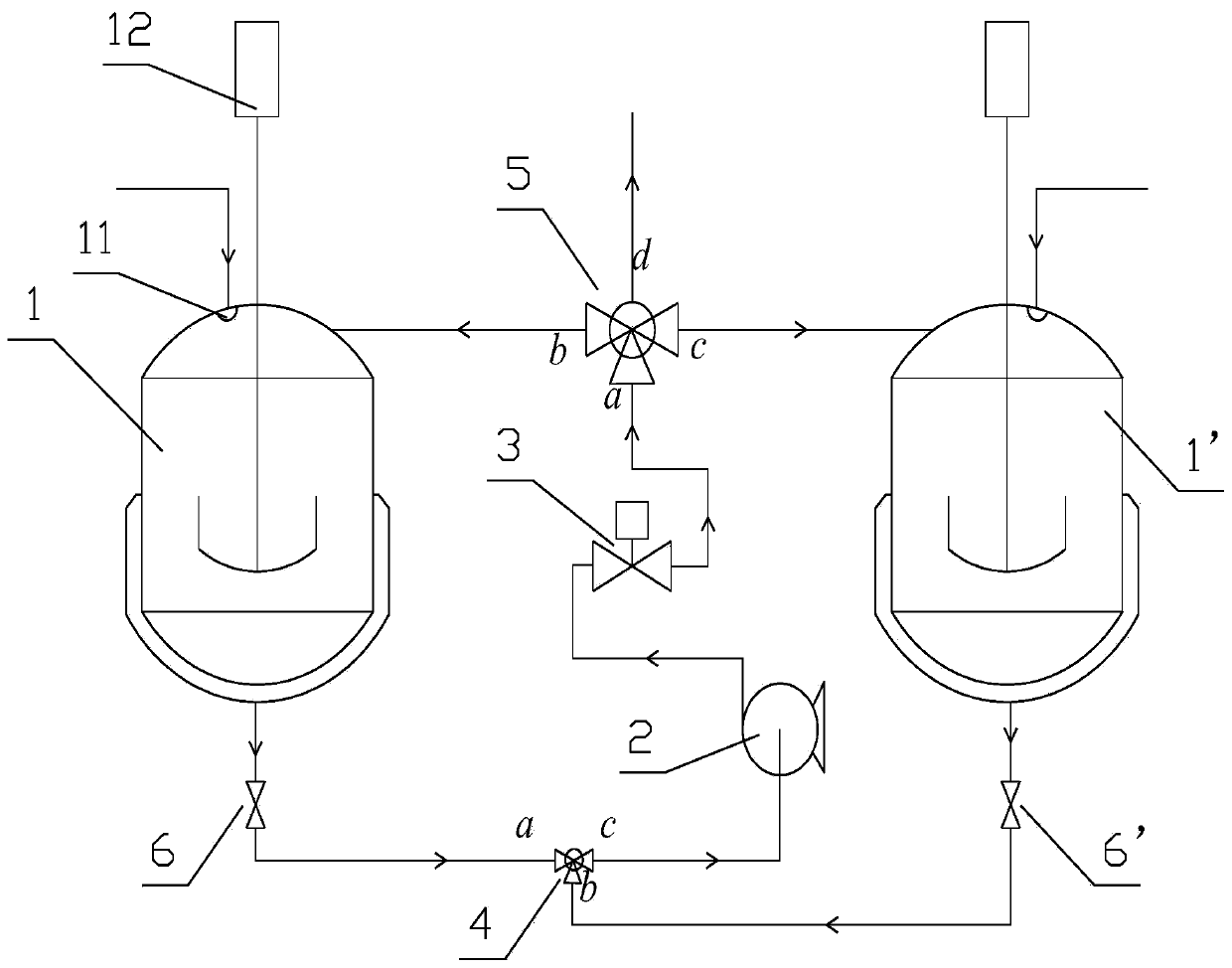

[0026] According to an embodiment of the present invention, a method for preparing a homogeneous catalyst slurry with a controllable concentration comprises the following steps:

[0027] ⑴. Stir the catalyst in the vacuum container until all the catalyst is flying up in the form of dust;

[0028] ⑵. Inject water mist into the container to fully wet the catalyst;

[0029] ⑶. Then inject the preset ingredients into the container and mix with the catalyst to get the slurry;

[0030] ⑷. Homogenize the slurry.

[0031] In the vacuum container, the catalyst powder is stirred so that the catalyst powder is in a dusty state and fills the entire container. By injecting water mist into the container, the wetting of the catalyst is realized to the maximum extent, which avoids the catalyst being exposed and oxidized, and facilitates the next step. The preset ingredients are injected into the container, which can be mixed with the catalyst to form a slurry, which is beneficial to the sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com