Temperature control system of exothermic reaction process

A temperature control system and exothermic reaction technology, applied in the chemical industry, can solve problems such as the decrease of circulating water flow, the inability to remove the reaction heat in time, and the out-of-control oxidation reaction temperature, so as to slow down the temperature rise, increase the correction time, and realize the fault state Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

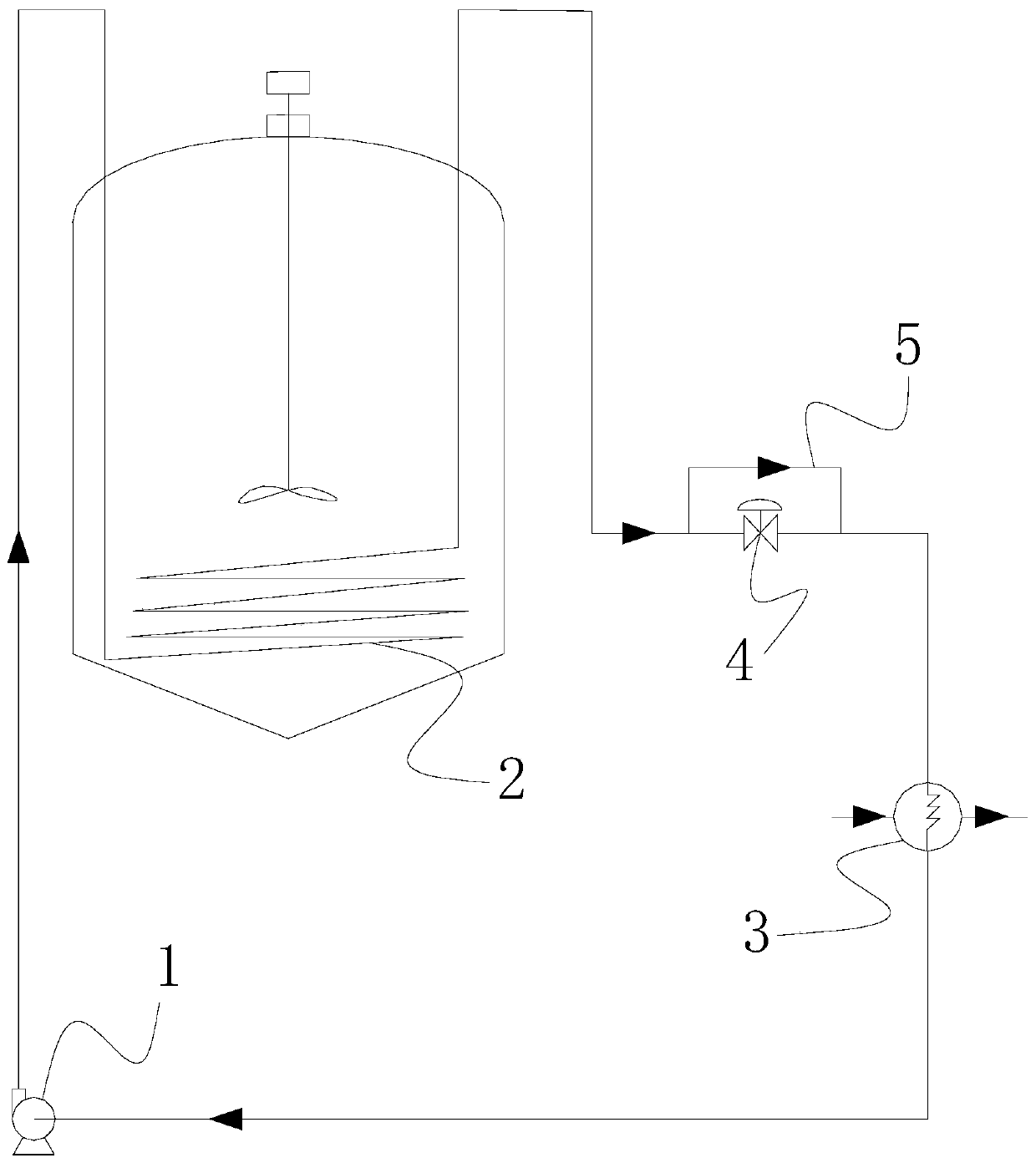

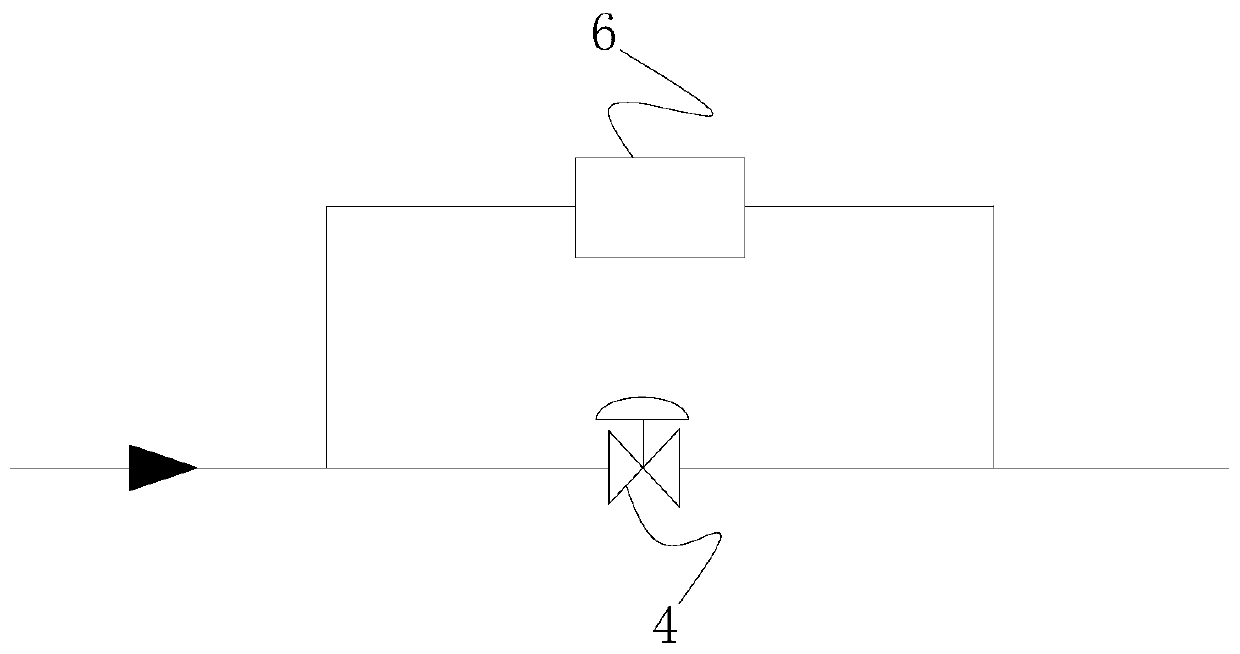

[0027] see figure 1 and figure 2 , the temperature control system of the exothermic reaction process includes a driving pump 1 , a first heat exchanger 2 , a second heat exchanger 3 , and a flow controller 4 . The first heat exchanger 2 is used to absorb the heat of the exothermic reaction process, and the second heat exchanger 3 is used to release heat to the outside. In this embodiment, the first heat exchanger is a serpentine tube, and the serpentine tube The upstream end of the coiled tube is the cooling medium inlet, the downstream end of the serpentine tube is the cooling medium outlet, the second heat exchanger is a tube heat exchanger, the cooled medium passes through the tube side of the tube heat exchanger, and the cooling medium passes through the tube side The shell side of the heat exchanger passes through. Of course, the second heat exchanger can also be a plate heat exchanger, which uses air to passively dissipate heat. The cooling medium inlet of the first h...

Embodiment 2

[0030] Take the temperature control of nitric acid oxidation reaction process in the process of producing adipic acid as an example. see figure 1, placing the first heat exchanger in the oxidation reactor, injecting cooling water into the closed circulation line, driving the pump to drive the cooling water to circulate in the closed circulation line, the flow controller is electrically connected to the temperature sensor in the oxidation reactor, To achieve the purpose of automatic flow adjustment. Use nitric acid, alcohol and ketone (or cyclohexanol) as raw materials, and put them into the oxidation reactor. When the reaction proceeds, the temperature in the oxidation reactor rises, and the cooling water heats up at the first heat exchanger, and the heat in the oxidation reactor Take away, keep the temperature in the oxidation reactor stable, the cooling water after heating is cooled at the second heat exchanger, and pumped back to the first heat exchanger through the drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com