Novel universal joint handheld laser welding gun

A new type of laser welding technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of damage to protective mirror parts, poor flexibility, and less freedom of cable swing, so as to improve work efficiency and avoid Damage, increased steering freedom effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

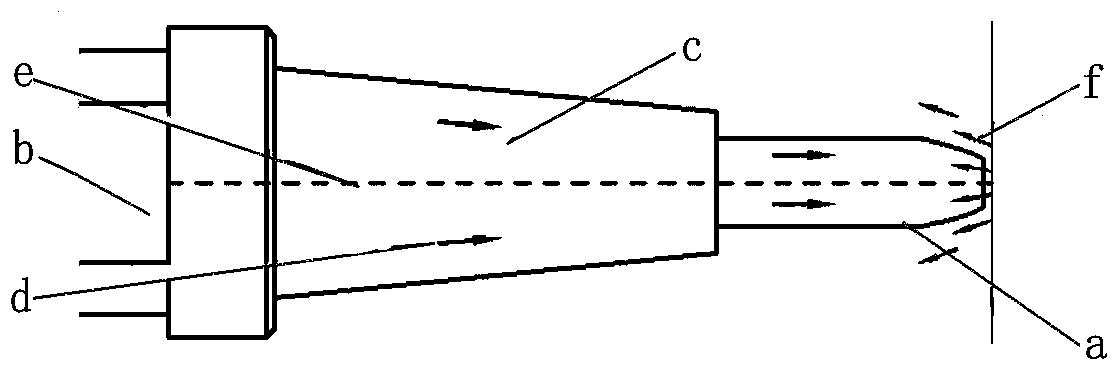

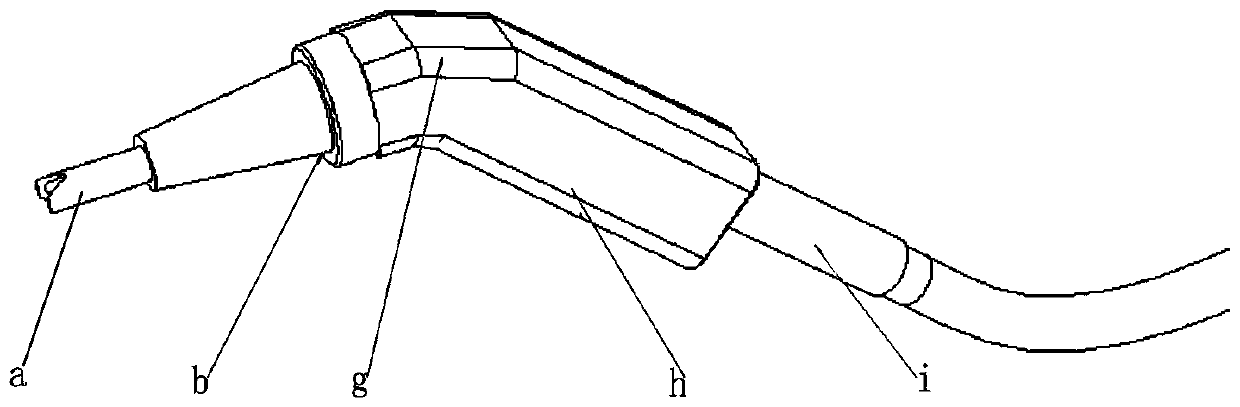

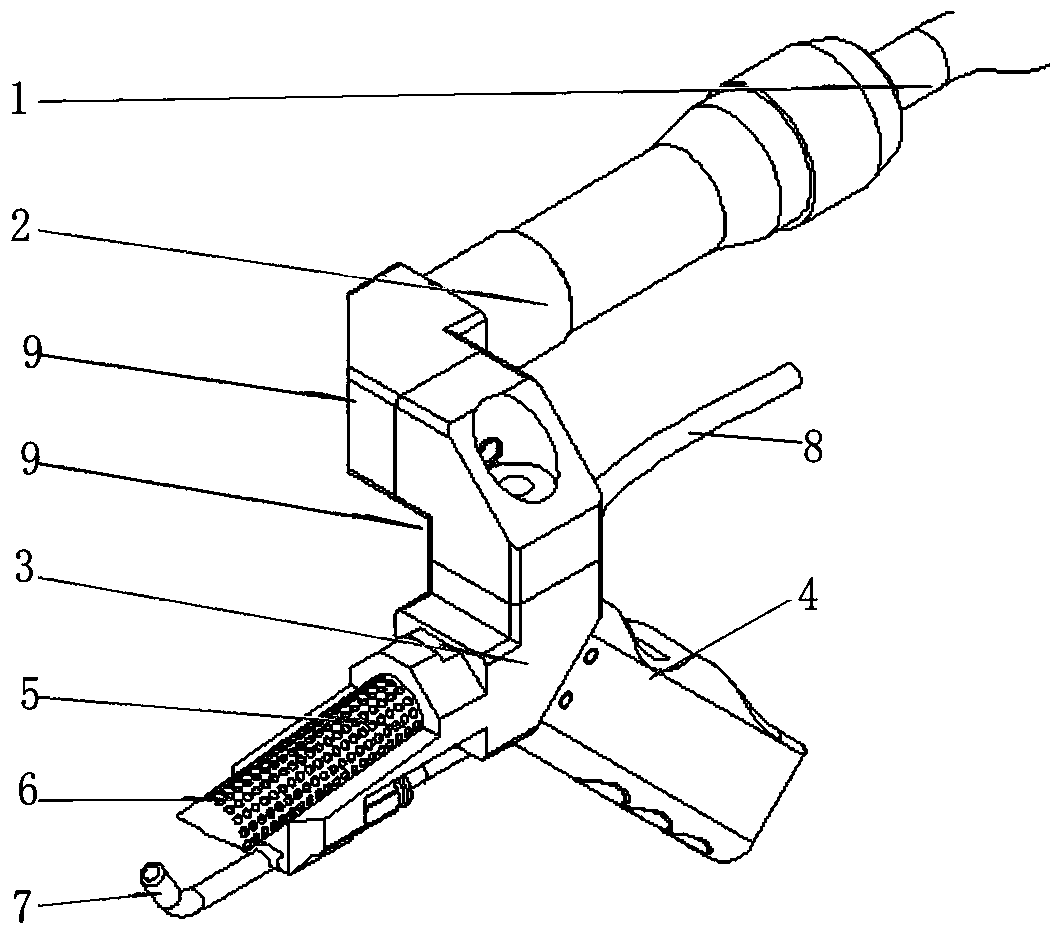

[0017] Example: see figure 1 , figure 2 , image 3 and Figure 4 , in the figure, 1-optical fiber optic cable part, 2-collimating mirror part, 3-focusing mirror part, 4-gun handle part, 5-protective mirror part, 6-protective part, 7-gun nozzle part, 8-protection Airpipe, 9-turning reflector part; a-gun nozzle part, b-protective mirror part, c-light shooting channel, d-shielding gas, e-laser beam, f-welding dust residue, g-focusing reflective lens, h - Collimating mirror parts, i-fiber optic cable parts.

[0018] The new type of hand-held laser welding torch with universal head, two turning mirror parts 9 connected to each other are arranged between the collimating mirror part 2 and the focusing mirror part 3 in the existing laser welding torch, so as to increase the degree of freedom of steering at the cable connection , and change the structure of its gun nozzle part 7, from the gas protection channel and the light injection channel to one channel into independent channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com