A kind of solid propellant with nitrated hydroxyl-terminated polybutadiene as binder

A technology for nitrating hydroxyl-terminated polybutadiene and solid propellant, which is used in explosives and other directions, can solve the problems of unsatisfactory mechanical properties of propellants, insufficient optimization of NHTPB structure and formula composition, etc., and achieves good process performance and mechanical performance, The effect of improving mechanical properties and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

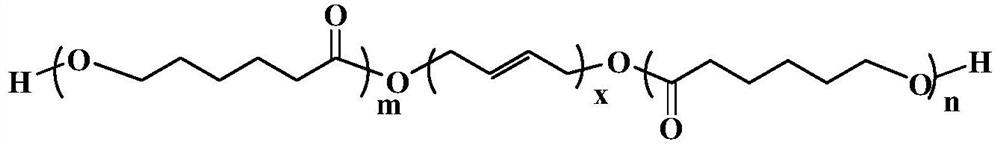

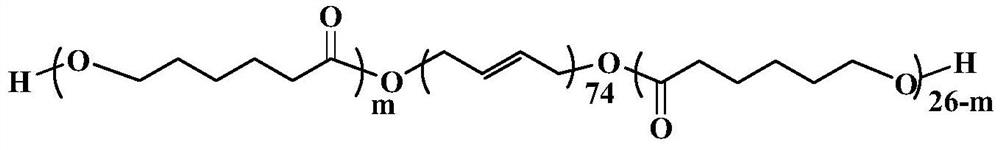

[0028] A kind of solid propellant with nitrated hydroxyl-terminated polybutadiene as binder, it uses nitrated hydroxyl-terminated polybutadiene as binder, the molecular weight of nitrated hydroxyl-terminated polybutadiene is 3988, and the hydroxyl value is 0.45mmol / g , the mass fraction of nitrate ester groups is 5.4%, and the polyester-butylene hydroxyl block polymer is used as a network regulator, and its structure is as follows:

[0029]

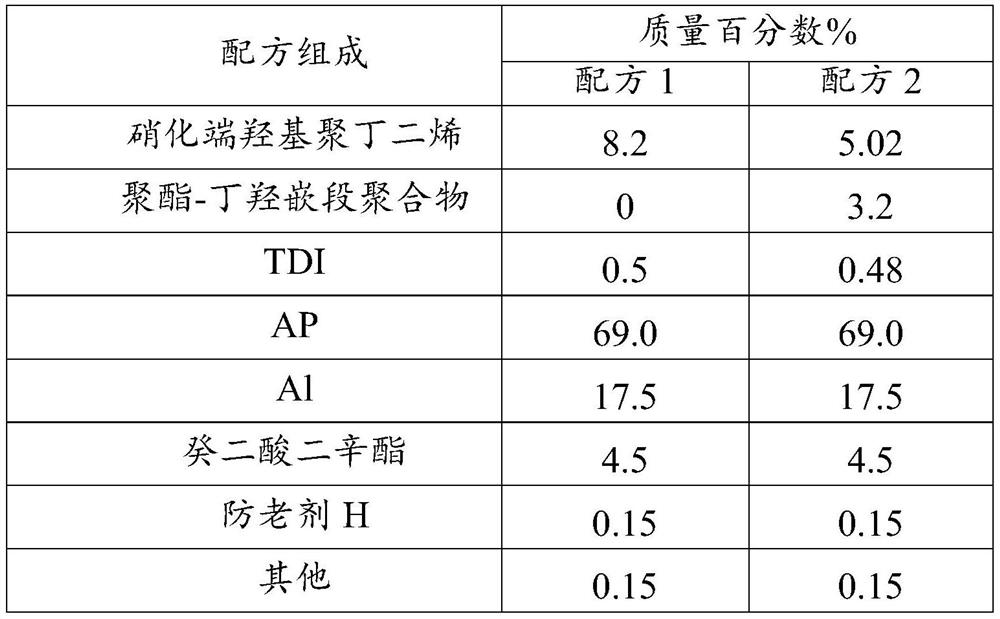

[0030] For comparison, two formulations containing the above-mentioned binder are provided, the formulation containing the above-mentioned binder and the network regulator is designated as formulation 2, and the formulation that only contains the above-mentioned binder but does not contain the above-mentioned network regulator is designated as the formulation 1, two kinds of propellant formulations (each component is by mass percentage) as shown in Table 1:

[0031] Table 1 Propellant formula with nitrated hydroxyl-terminated polybutad...

Embodiment 2

[0040] A kind of solid propellant with nitrated hydroxyl-terminated polybutadiene as binder, with nitrated hydroxyl-terminated polybutadiene as binder, the molecular weight of nitrated hydroxyl-terminated polybutadiene is 3988, and the hydroxyl value is 0.48mmol / g, The mass fraction of nitrate ester groups is 7.03%; the polyester-butylene hydroxyl block polymer is used as a network regulator, and the polyester-butylene hydroxyl block polymer structure is as follows:

[0041]

[0042] This propellant formula (each component is by mass percent, marked as formula 3) is as shown in table 3:

[0043] Table 3 Propellant formula with nitrated hydroxyl-terminated polybutadiene as binder

[0044]

[0045] The solid content in formula 3 is 87%, with nitrated hydroxyl-terminated polybutadiene as binder, polyester-butylene hydroxyl block polymer network regulator, and adding nitro-containing energetic plasticizer bis 2,2-dinitrododecanol formal, to improve the energy performance of t...

Embodiment 3

[0050] A kind of solid propellant with nitrated hydroxyl-terminated polybutadiene as binder, with nitrated hydroxyl-terminated polybutadiene as binder, the molecular weight of nitrated hydroxyl-terminated polybutadiene is 4100, and the hydroxyl value is 0.46mmol / g, The mass fraction of nitrate ester groups is 6.35%; the polyester-butylene hydroxyl block polymer is used as a network regulator, and its structure is as follows:

[0051]

[0052] For comparison, two different formulations including the above adhesive and network regulator are provided, formulation 4 and formulation 5, the solid content of formulation 4 and formulation 5 are both 86.5%, the difference between the two is only the amount of network regulator There are differences, two propellant formulations (each component is by mass percentage) as shown in table 5:

[0053] Table 5 is the propellant formulation of binder with nitrated hydroxyl-terminated polybutadiene

[0054]

[0055] The mechanical propert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com