Water-based non-cured rubber asphalt waterproof paint and production technology thereof

An asphalt waterproof coating, non-curing rubber technology, applied in asphalt coatings, coatings, conjugated diene coatings, etc., can solve the problems of reducing material performance, waste of energy and environment, pollution, etc. Healing performance, excellent creep effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

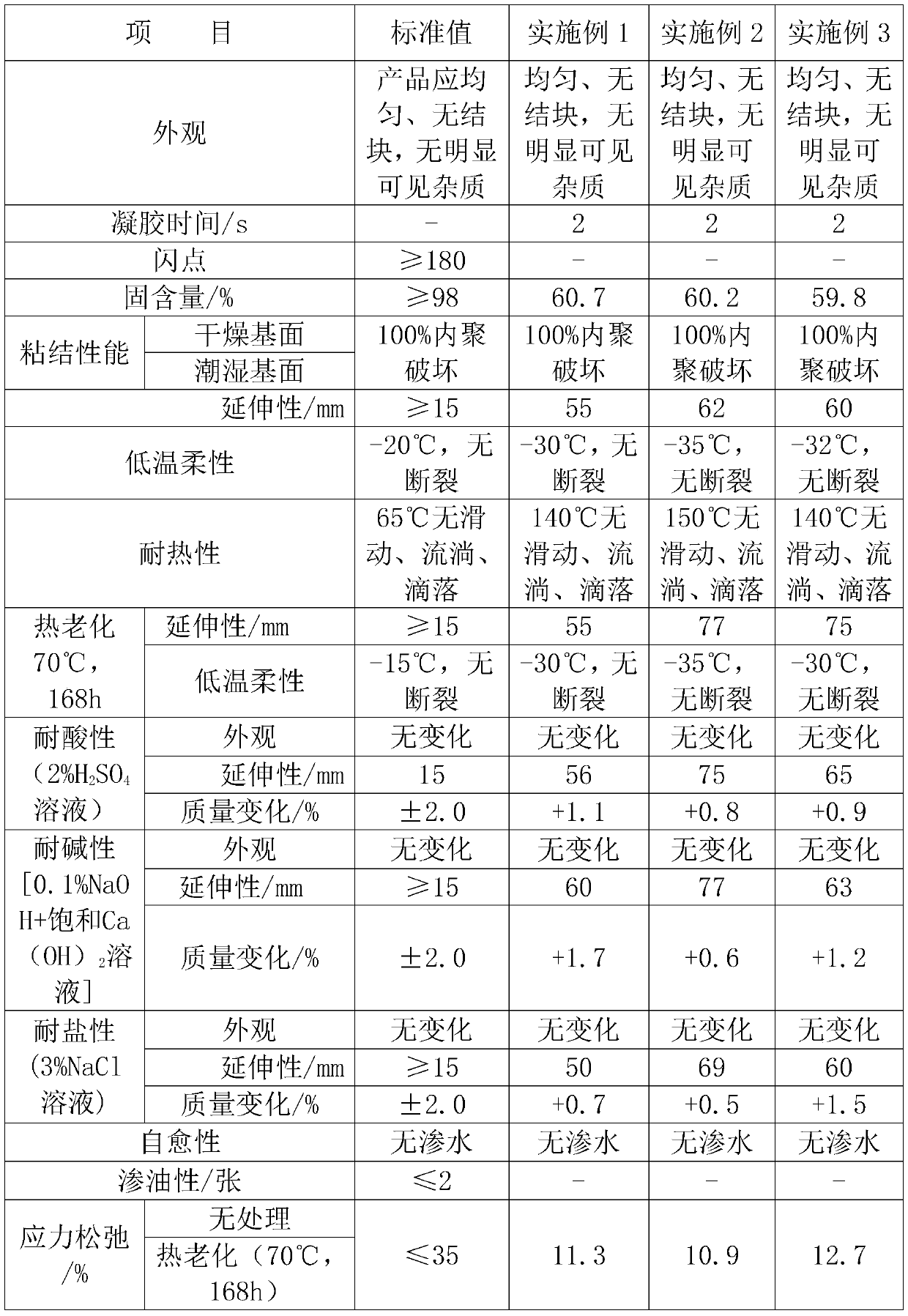

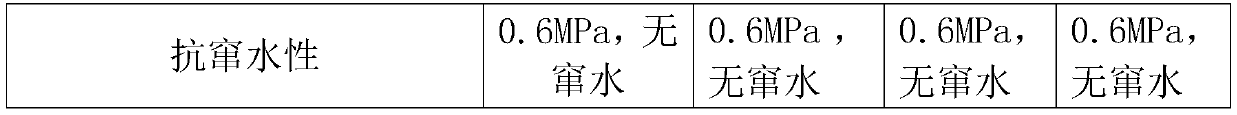

Embodiment 1

[0026] Mix 40 parts of asphalt, 2 parts of engine oil, 3 parts of naphthenic oil and 9 parts of aromatic oil, heat up to 150°C, add 2 parts of SBR and stir for 1 hour, then heat up to 180°C-190°C, add 1.5 parts of SBS and stir for 1 hour Then add 2 parts of tackifying resin and stir for 0.5 hours, then high-speed shear for 2 hours, then add 0.5 parts of plasticizer and stir for 0.5 hours to obtain mixture I.

[0027] Mix 2 parts of asphalt emulsifier and 36 parts of distilled water, stir evenly and raise the temperature to 50°C-60°C, add sodium peroxide to adjust the pH to 11-13, and then add 0.1 part of defoamer to make mixture II. Mixture II was emulsified with mixture I at 180°C-190°C through a colloid mill to prepare mixture III.

[0028] Mix 0.1 part of dispersant, 20 parts of latex, mixture III, 0.1 part of bactericide, 0.1 part of defoamer, and 1 part of thickening emulsion and stir for 0.5 hours, then slowly add 3 parts of filler, stir for 1.5 hours and stop stirring, ...

Embodiment 2

[0031] Mix 40 parts of asphalt, 2 parts of engine oil, 3 parts of naphthenic oil and 9 parts of aromatic oil, heat up to 150°C, add 2 parts of SBR and stir for 1 hour, then heat up to 180°C-190°C, add 1.5 parts of SBS and stir for 1 hour Then add 2 parts of tackifying resin and stir for 0.5 hours, then high-speed shear for 2 hours, then add 0.5 parts of plasticizer and stir for 0.5 hours to obtain mixture I.

[0032] Mix 2 parts of asphalt emulsifier and 36 parts of distilled water, stir evenly and raise the temperature to 50°C-60°C, add sodium peroxide to adjust the pH to 11-13, and then add 0.1 part of defoamer to make mixture II. Mixture II was emulsified with mixture I at 180°C-190°C through a colloid mill to prepare mixture III.

[0033] Mix 0.1 part of dispersant, 25 parts of latex, mixture III, 0.1 part of bactericide, 0.1 part of defoamer, and 1 part of thickening emulsion and stir for 0.5 hours, then slowly add 3 parts of filler, stir for 1.5 hours and stop stirring, ...

Embodiment 3

[0036] Mix 40 parts of asphalt, 2 parts of engine oil, 3 parts of naphthenic oil and 14 parts of aromatic oil, heat up to 150°C, add 2 parts of SBR and stir for 1 hour, then heat up to 180°C-190°C, add 1.5 parts of SBS and stir for 1 hour Then add 2 parts of tackifying resin and stir for 0.5 hours, then high-speed shear for 2 hours, then add 0.5 parts of plasticizer and stir for 0.5 hours to obtain mixture I.

[0037] Mix 2 parts of asphalt emulsifier and 36 parts of distilled water, stir evenly and raise the temperature to 50°C-60°C, add sodium peroxide to adjust the pH to 11-13, and then add 0.1 part of defoamer to make mixture II. Mixture II was emulsified with mixture I at 180°C-190°C through a colloid mill to prepare mixture III.

[0038] Mix 0.1 part of dispersant, 25 parts of latex, mixture III, 0.1 part of bactericide, 0.1 part of defoamer, and 1 part of thickening emulsion and stir for 0.5 hours, then slowly add 3 parts of filler, stir for 1.5 hours and stop stirring,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com