Cooling system additive solution as well as preparation method and use method thereof

A technology of cooling system and adding liquid, which is applied in the direction of chemical instruments and methods, heat exchange materials, etc., can solve the problems of large economic burden and waste of resources, and achieve the effects of inhibiting corrosion, avoiding corrosion, saving social resources and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

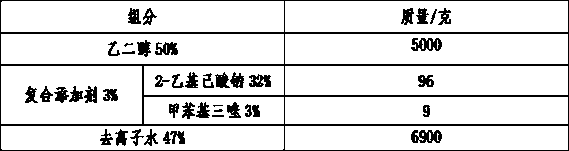

[0030] This embodiment provides a cooling system additive liquid, the components of the additive liquid and the quality of each component are:

[0031]

[0032] The composite additive selected in the present invention is a cooling system corrosion inhibitor, and its active ingredients are sodium 2-ethylhexanoate and tolyltriazole, which do not contain traditional inorganic salt components, effectively avoiding damage to the metal parts of the engine cooling system. Corrosion, good compatibility with the formulation system, excellent storage stability, does not react with other inorganic salt additives and organic additives, after mixing with other cooling fluids, it can play a synergistic and anti-corrosion effect. Its organic corrosion inhibitor molecules can be effectively adsorbed on the metal surface, inhibit the occurrence of corrosion of metal parts, and ensure that the antifreeze coolant can work safely and for a long time.

Embodiment 2

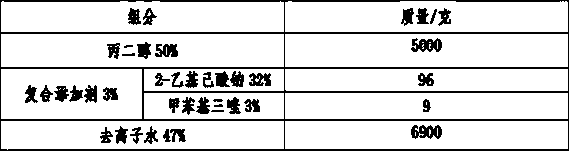

[0039] This embodiment provides a cooling system additive liquid, the components of the additive liquid and the quality of each component are:

[0040]

[0041] The preparation method of cooling system additive fluid comprises the following steps:

[0042] (1) Under normal temperature and normal conditions, weigh 5,000 grams of ethylene glycol and 4,700 grams of deionized water and add them to container A, and turn on the stirrer, stir at a low speed for 3 minutes at a stirring speed of 120 r / min, and mix well;

[0043] (2) Weigh 300 grams of composite additives into container A, increase the stirring speed for high-speed stirring, the stirring speed is 400r / min, stir for 15 minutes, mix evenly, and the finished product is obtained.

Embodiment 3

[0045] This embodiment provides a cooling system additive liquid, the components of the additive liquid and the quality of each component are:

[0046]

[0047] The preparation method of the cooling system additive liquid comprises the following steps:

[0048] (1) Under normal temperature and normal conditions, weigh 6,500 grams of ethylene glycol and 3,000 grams of deionized water and add them to container A, and turn on the stirrer, stir at a low speed for 5 minutes at a stirring speed of 150 r / min, and mix well;

[0049] (2) Weigh 500 grams of composite additives into container A, increase the stirring speed for high-speed stirring, the stirring speed is 500r / min, stir for 25 minutes, and mix evenly to obtain the finished product.

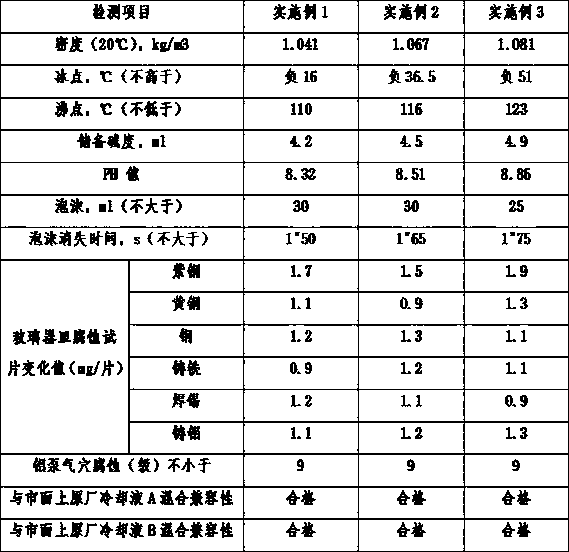

[0050] According to the cooling system additive liquid prepared in embodiment 1-3, the various indicators after testing are as follows:

[0051]

[0052] It can be seen from the above table results that the special additive liquid for the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com