Recovery device and method of furnace bottom steel slag of steel-making furnace

A recovery device and steelmaking furnace technology, applied in the direction of recycling technology, chemical instruments and methods, and improvement of process efficiency, can solve the problems of increasing difficulty and cost, consuming water resources, and large waste particle size, so as to reduce the pressure on the site and environmental impact, to solve the effect of high smelting cost and simple centralized equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

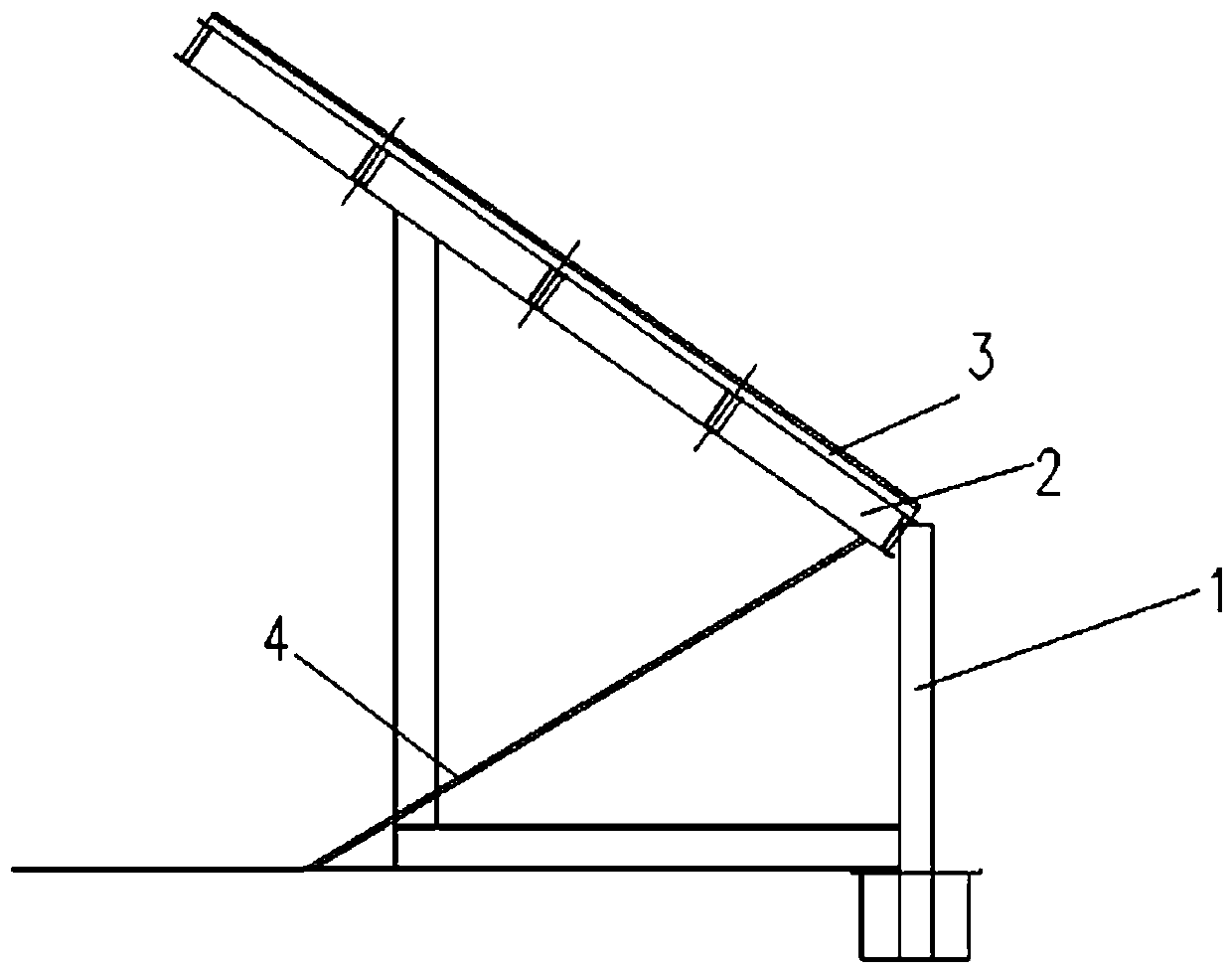

[0028] Such as figure 1 As shown, a recovery device for steel slag under a steelmaking furnace includes a screening assembly. The screening assembly includes four rectangular supports 1 arranged vertically on the ground. The horizontal height of the two supports 1 on one side is greater than The horizontal height of the two supports 1 on the other side, the support 1 is equipped with a screen frame 2 with an opening in the middle of the surface, and a screen cloth 3 is laid on the screen frame 2.

[0029] Specifically, one side of the bottom wall of the screen frame 2 is connected with a slag guide plate 4, and the other end of the slag guide plate 4 is tilted against the ground, and the angle between the slag guide plate 4 and the screen frame 2 is 35 degrees. 4 The angle formed with the ground is 31 degrees. In order to have a larger scope of appl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com