Waterborne bag/case leather suction-texturing process

A water-based technology for luggage leather, applied in textiles and papermaking, can solve problems such as waste water generation, hidden dangers to human health and safety, and environmental pollution, and achieve the effect of not being easily damaged, with a strong three-dimensional pattern and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] Embodiment: a kind of water-based luggage leather absorbing pattern process, concrete steps are as follows:

[0036] Step 1: Wet Mixing Ingredients:

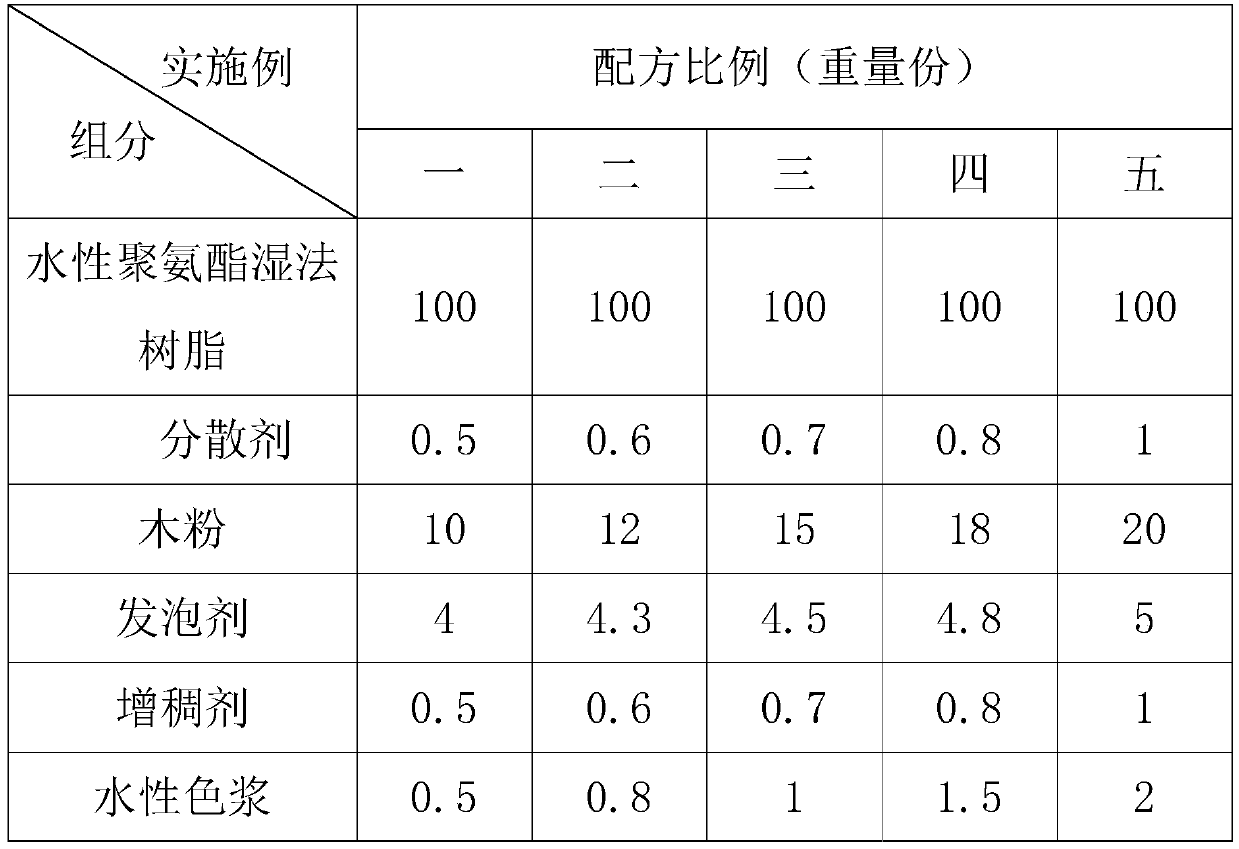

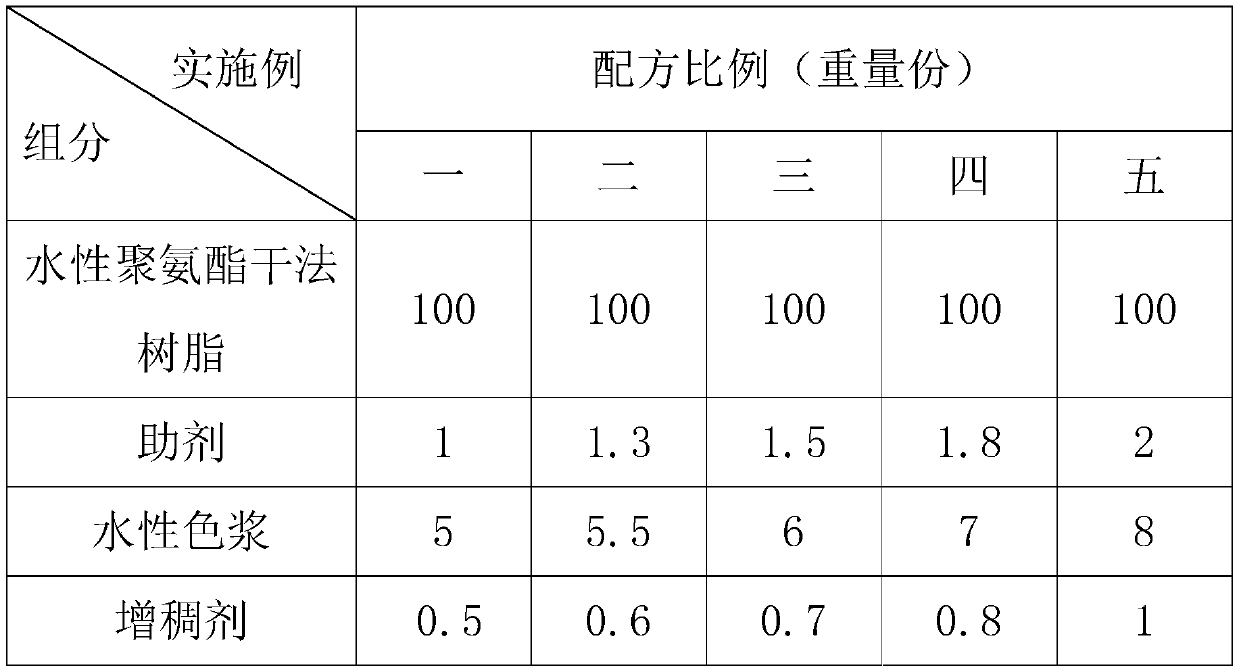

[0037] Prepare wet ingredients according to the table below:

[0038]

[0039] a. According to the above ingredient list, add water-based polyurethane wet-process resin to the reaction kettle and stir at a low speed of 400 rpm-800 rpm, add a dispersant, and then slowly add wood powder and stir at a speed of 4000 rpm- Stir at a speed of 6000 rpm for 30 minutes;

[0040] b. After the water-based polyurethane wet-process resin and wood powder are fully stirred evenly, add foaming agent and stir for about 5 minutes according to the formula, and the stirring speed is reduced to 300-400 rpm. Slowly add the thickener, and then pay attention to observe the dispersion during the thickening process to control the speed of addition, and the speed is controlled at 500-600 rpm;

[0041] c. After all the materials are added, chec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com