Eddy current-based rotation angle measuring device

A technology of rotation angle measurement and eddy current, which is applied in the direction of measuring devices, electric devices, and electromagnetic means, etc., can solve the problems of circular grating angle measurement accuracy improvement, high price, high machining accuracy and installation accuracy of mechanical axis, and achieve measurement Expanded range, improved measurement accuracy, and convenient implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the specific embodiments and the accompanying drawings. It should be understood that these descriptions are exemplary only and are not intended to limit the scope of the invention. Also, in the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concepts of the present invention.

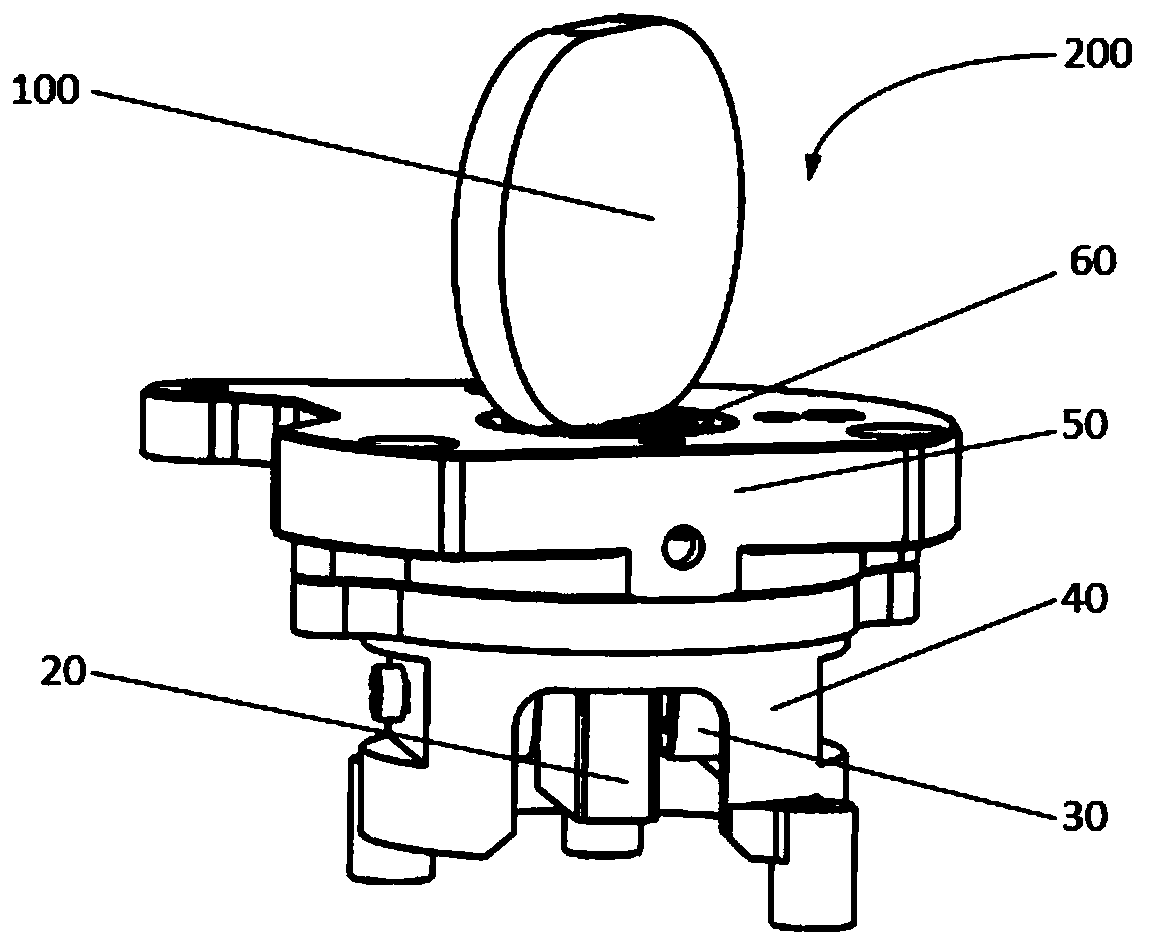

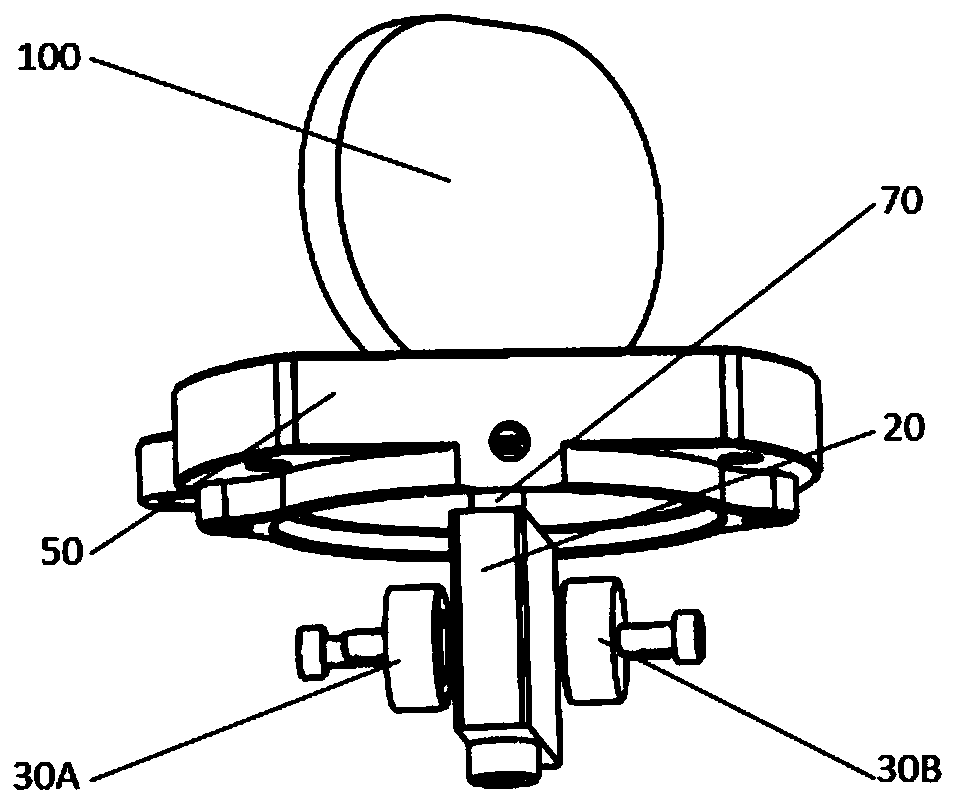

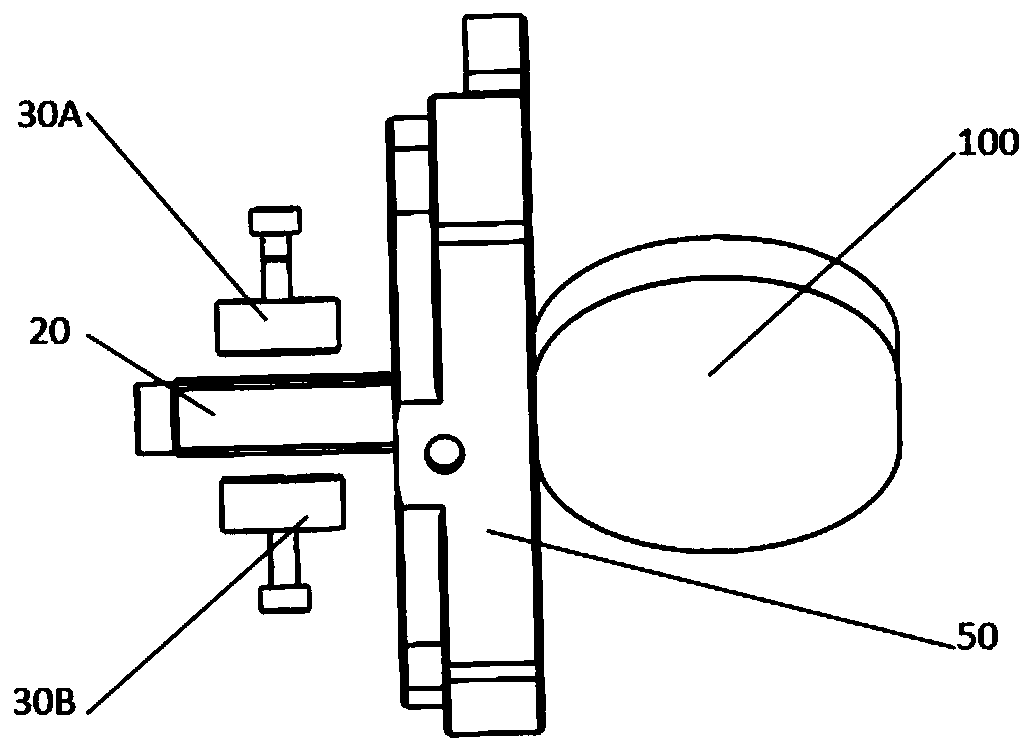

[0031] figure 1 is the three-dimensional view of the one-dimensional rotation angle measuring device based on the eddy current of the present invention, figure 2 Yes figure 1 A perspective view of the rotation angle measuring device shown with the sensor holder removed. from figure 1 and figure 2It can be seen that the rotation angle measuring device 200 mainly includes a fixed part and a rotating part, wherein the fixed part mainly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com