Optical measurement method for resistivity of semiconductor material

An optical measurement and semiconductor technology, used in measurement devices, analysis materials, measurement of electrical variables, etc., can solve the problems of increasing measurement errors, large probe sampling volume, material surface damage, etc., to improve measurement accuracy and small volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

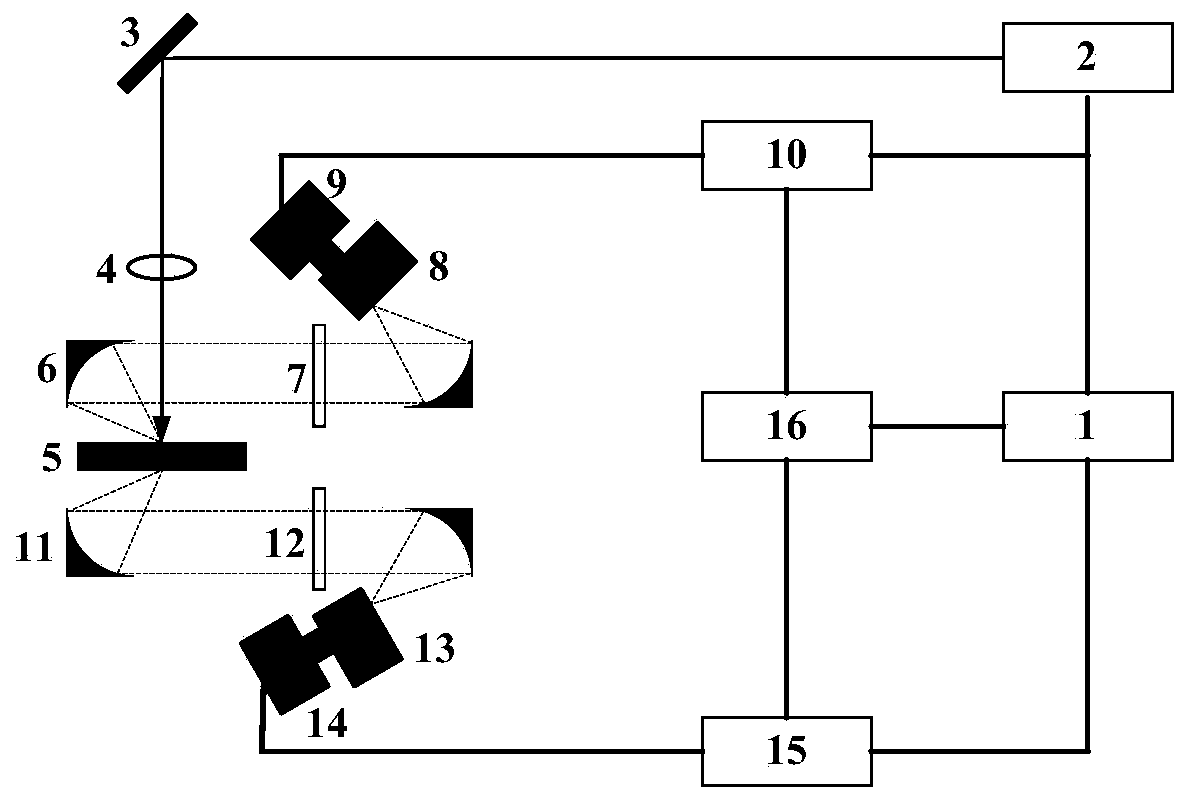

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0024] Principle of the present invention is:

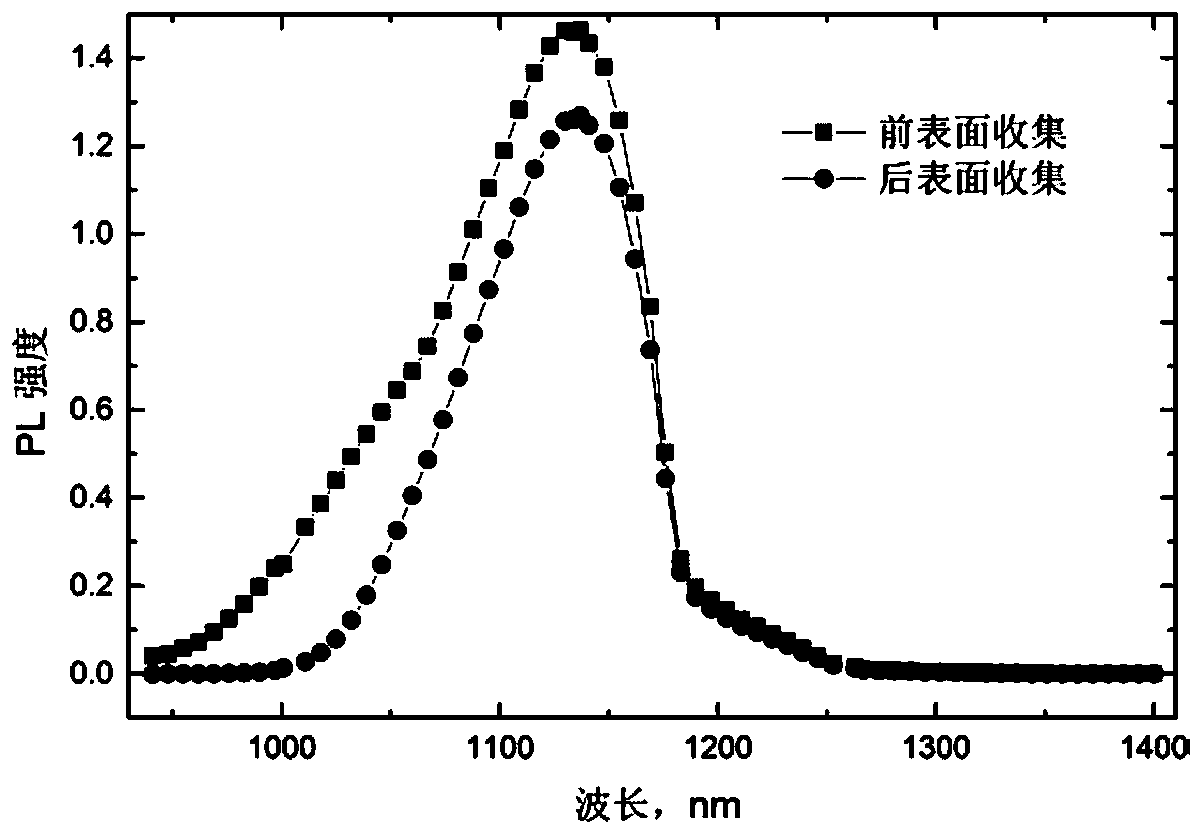

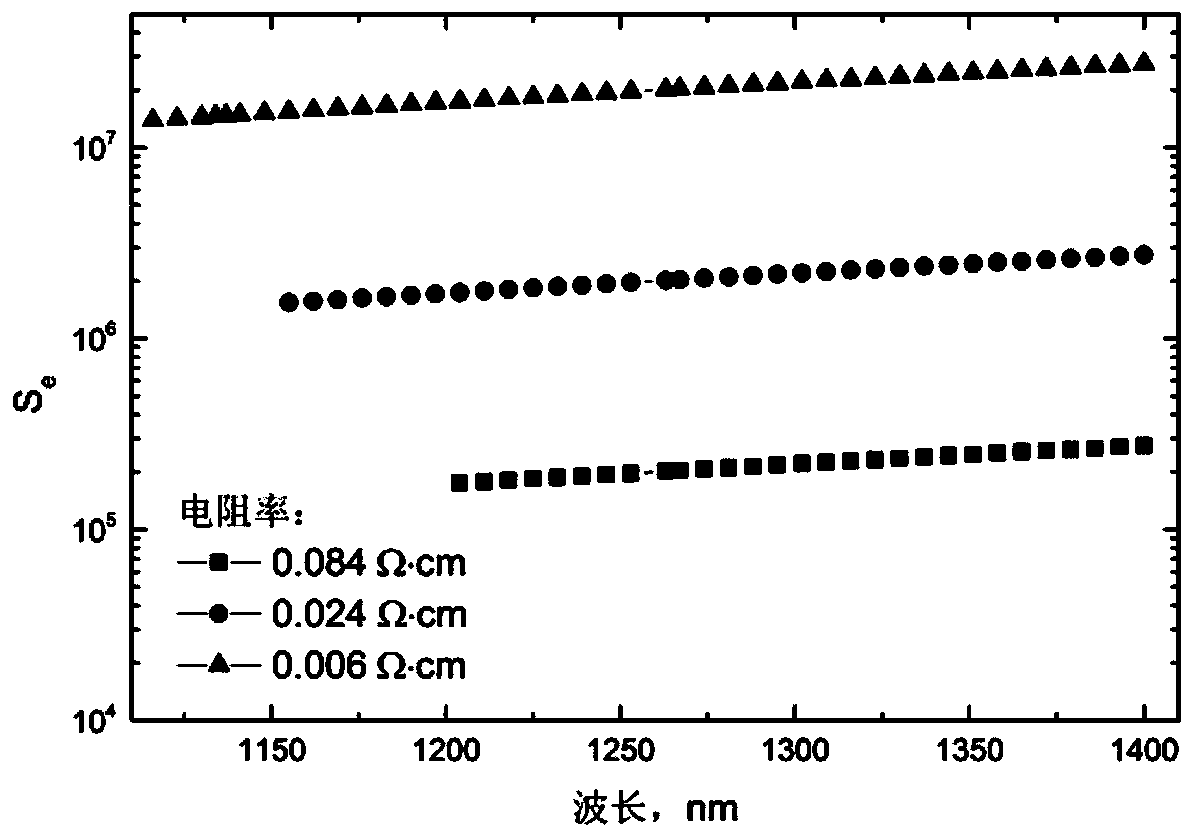

[0025] The semiconductor material absorbs the pump beam with photon energy greater than its forbidden band width to generate excess carriers, and the excess carriers generate photons after radiation recombination, and the photons are reabsorbed by the material during the transmission to the front and back surfaces. The size of the coefficient is related to the photon energy, plus the difference in the photon transmission path, the front and rear surfaces are collected and measured with different photoluminescence spectra. The reabsorption of photons ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com