Method of evaluating base number retention of clearing agents

A detergent and retention technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of evaluation of base value retention without detergent, etc., and achieve the effect of easy implementation of evaluation means, simple operation, and simplified design process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

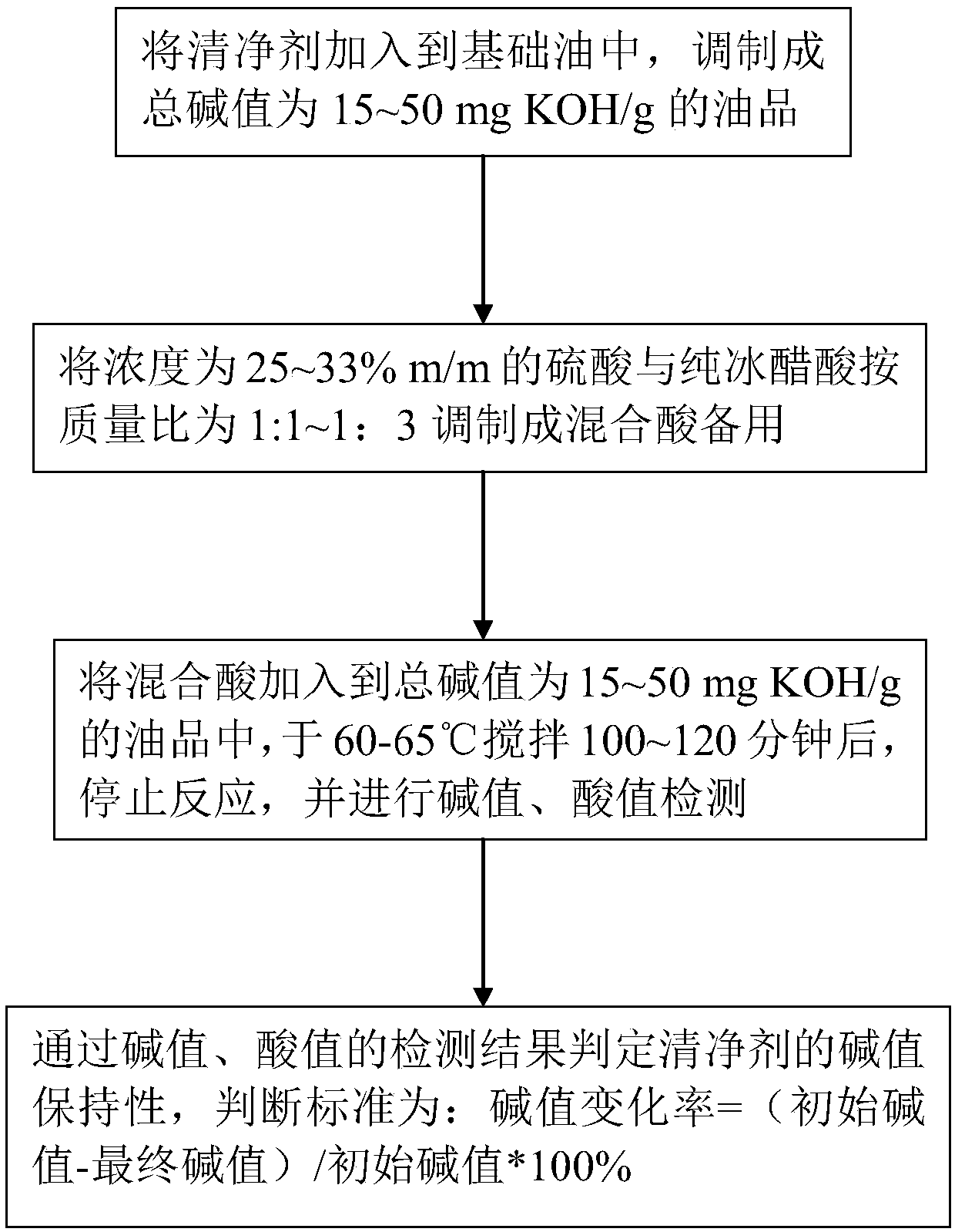

Method used

Image

Examples

Embodiment 1

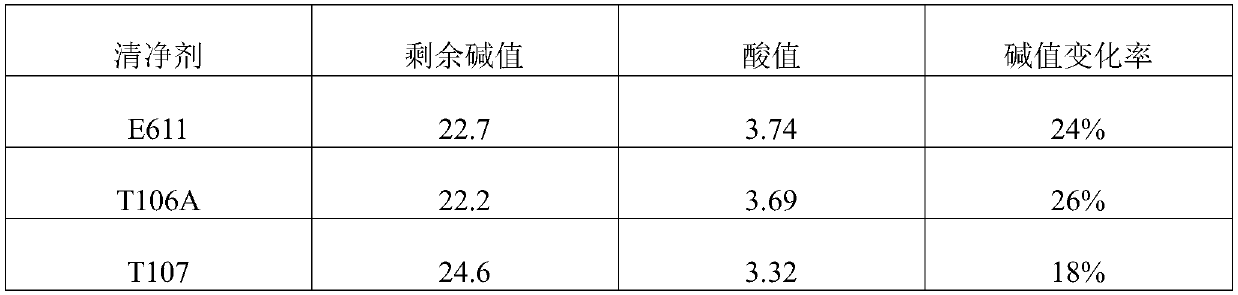

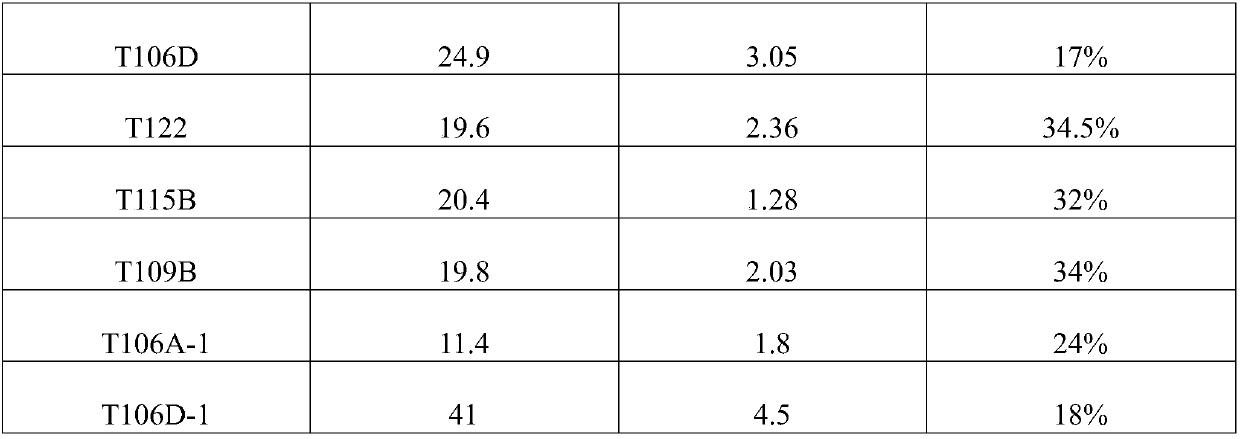

[0064] The present embodiment provides a method for evaluating the alkalinity retention of detergent, comprising the following steps:

[0065] Take 10g of alkylsulfonate detergent E611 with a base value of 300mg KOH / g, add it to 90g of HVI400SN base oil, stir at 60°C for 30 minutes, stop stirring after fully mixing, and prepare a mixed oil with TBN of 30mg KOH / g Taste.

[0066] Place a 250mL single-necked flask in a water bath with a magnetic stirrer and heating function, add 100g of the above-mentioned mixed oil into the flask, place a magnetic stirrer, set the temperature of the water bath to 60°C, and start stirring .

[0067] Mix sulfuric acid (33%m / m) and glacial acetic acid (pure) at a ratio of 1:3 to make a mixed acid. And take 4mL of the above mixed acid and add it to the dropping funnel, then add it dropwise to the mixed oil, and complete the dropwise addition within 30 minutes.

[0068] Keep stirring for 120 minutes, and it can be observed that there is continuous...

Embodiment 2

[0071] The present embodiment provides a method for evaluating the alkalinity retention of detergent, comprising the following steps:

[0072] Take 10g of alkylsulfonate detergent T106A with a base value of 300mg KOH / g, add it to 90g of HVI400SN base oil, stir at 60°C for 30 minutes, stop stirring after fully mixing, and prepare a mixed oil product with TBN 30mg KOH / g .

[0073] Place a 250mL single-necked flask in a water bath with a magnetic stirrer and heating function, add 100g of the above-mentioned mixed oil into the flask, place a magnetic stirrer, set the temperature of the water bath to 60°C, and start stirring .

[0074] Mix sulfuric acid (25% m / m) and glacial acetic acid (pure) at a ratio of 1:1 to make a mixed acid. And take 4mL of the above mixed acid and add it to the dropping funnel, then add it dropwise to the mixed oil, and complete the dropwise addition within 30 minutes.

[0075] Keep stirring for 120 minutes, and it can be observed that there is continuo...

Embodiment 3

[0078] The present embodiment provides a method for evaluating the alkalinity retention of detergent, comprising the following steps:

[0079] Take 7.5g of alkyl sulfonate detergent T107 with a base value of 400mg KOH / g, add it to 92.5g of HVI400SN base oil, stir at 60°C for 30 minutes, stop stirring after fully mixing, and prepare a mixture of TBN30mg KOH / g Oil.

[0080] Place a 250mL single-necked flask in a water bath with a magnetic stirrer and heating function, add 100g of the above-mentioned mixed oil into the flask, place a magnetic stirrer, set the temperature of the water bath to 65°C, and start stirring .

[0081] Mix sulfuric acid (33%m / m) and glacial acetic acid (pure) at a ratio of 1:3 to make a mixed acid. And take 4mL of the above mixed acid and add it to the dropping funnel, then add it dropwise to the mixed oil, and complete the dropwise addition within 30 minutes.

[0082] Keep stirring for 120 minutes, and it can be observed that there is continuous gas p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com