Minimal curved surface structure and manufacturing method thereof

A technology of extremely small curved surface and surface structure, which is applied in the field of extremely small curved surface structure and its production, can solve the problems of complicated process technology, long R&D and production cycle, manual work cannot be ruled out, and achieve the goal of reducing impact load and excellent cushioning performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

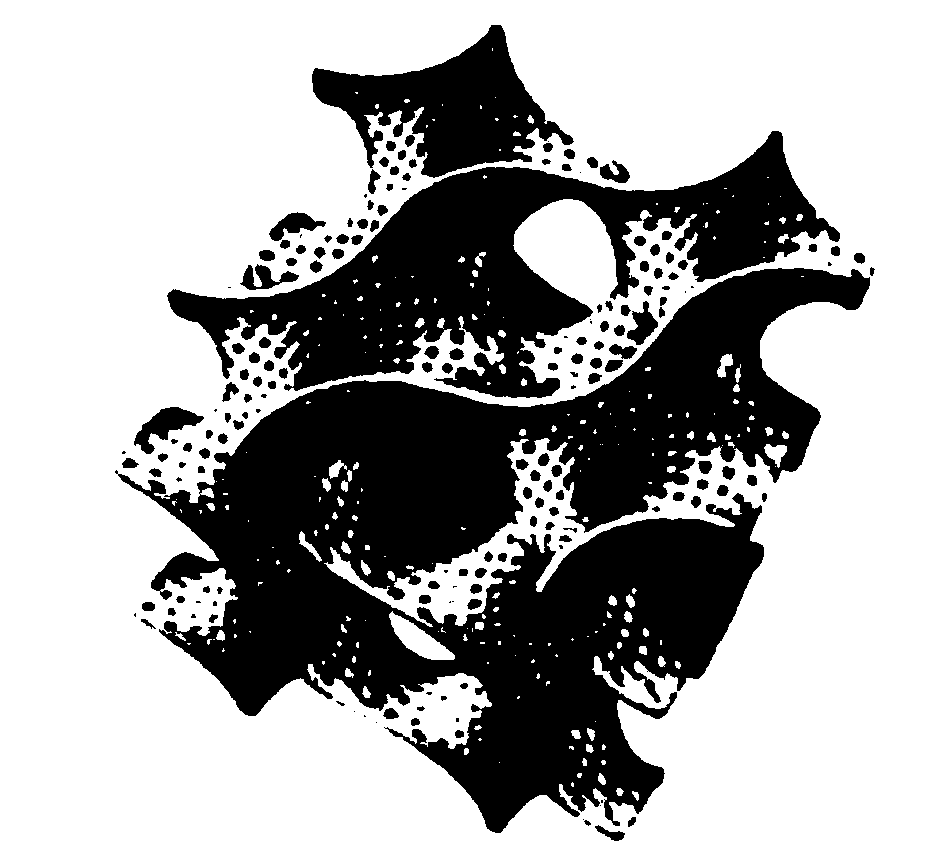

[0041] Such as figure 1 with 2 as shown,

[0042] figure 1 Schematic diagram of the side view structure of the shoe midsole made for the minimal curved surface in the present invention;

[0043] figure 2 Schematic diagram of the isometric view structure of the shoe midsole made for the minimal curved surface in the present invention;

[0044] The invention proposes a very small curved surface structure, the wall thickness of the surface structure of the structure is 0.3mm-4mm, and the side length of the unit structure is 3mm-20mm; the structure is filled and / or spliced and / or spliced by multiple 3D printed units or arrays and / or stages;

[0045]In an optional embodiment: the unit body is formed by filling and / or splicing and / or arraying and / or grading of multiple curved surfaces.

[0046] In an optional embodiment: the curved surface is composed of a curved surface defined by the formula set of cos(x)*sin(y)+cos(y)*sin(z)+cos(z)*sin(x)=0 .

[0047] In an optional ...

Embodiment 2

[0055] The invention also provides a method for making the extremely small curved surface structure;

[0056] Combining with the content of Example 1: the method is based on 3D printing manufacturing, as a preferred technical solution of a 3D printing method of the present invention: various types of 3D printing (or additive manufacturing) technologies can be used;

[0057] 3D printing or "three-dimensional printing" includes various techniques for forming three-dimensional objects by depositing successive layers of material on top of each other;

[0058] Exemplary 3D printing techniques that may be used include, but are not limited to: Fused Filament Fabrication (FFF), Electron Beam Free Forming (EBF), Direct Metal Laser Sintering (DMLS), Electron Beam Melting (EMB), Selective Laser Melting (SLM ), selective heat sintering (SHS), selective laser sintering (SLS), gypsum 3D printing (PP), layered object manufacturing (LOM), stereolithography (SLA), digital light processing (DLP...

Embodiment 3

[0079] The present invention also provides a kind of experimental data;

[0080] The load-bearing of the foot is often considered to be the joint load of the first metatarsophalangeal joint, the fifth metatarsophalangeal joint and the calcaneus. Therefore, the pressure response of the foot is graphically represented, and there are two large pressure-bearing areas of the forefoot and the calcaneus. Stress fractures are the result of bone being subjected to constant impact strain. Therefore, when designing the midsole of the shoe, the above-mentioned 3D printed extremely small curved surface structure is designed correspondingly for the two bearing areas of the forefoot and the backfoot where the plantar pressure is relatively high. When the human body is in motion, under the high impact load condition of the ground's reaction force against the human body, the forefoot and the heel are designed to be compressively deformed, resulting in a relatively short part of the midsole of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com