Electric-arc scale-welding fine welding device for steel tube

A technology of fish scales and steel pipes, which is applied in arc welding equipment, welding equipment, welding accessories, etc., can solve the problems of substandard strength accuracy, long time consumption, and great personal hazards, so as to achieve firm and smooth fish scale weld patterns, avoid solder shortage, and impurities little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

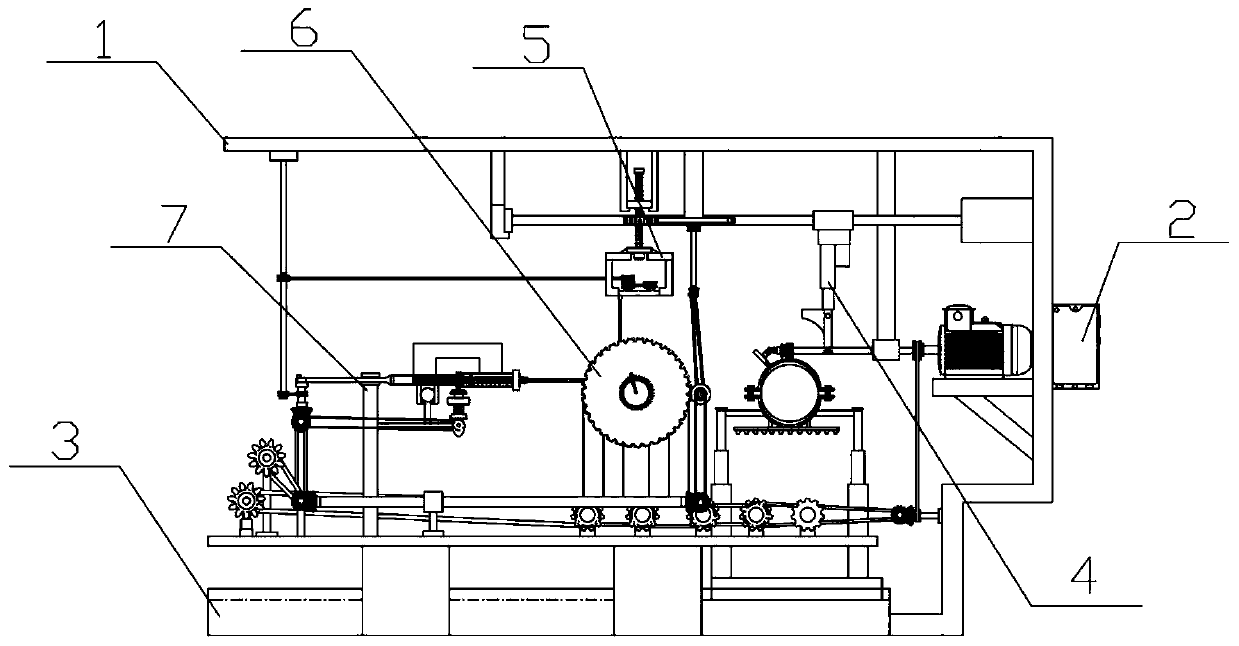

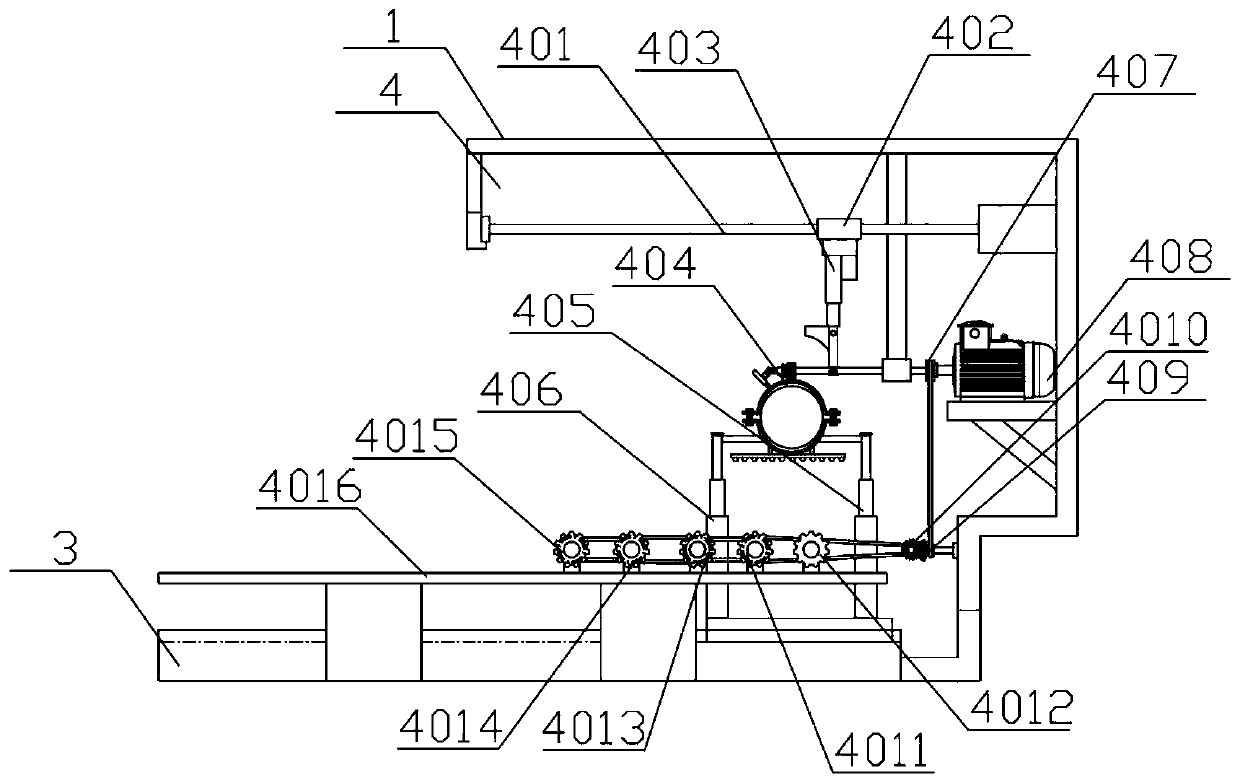

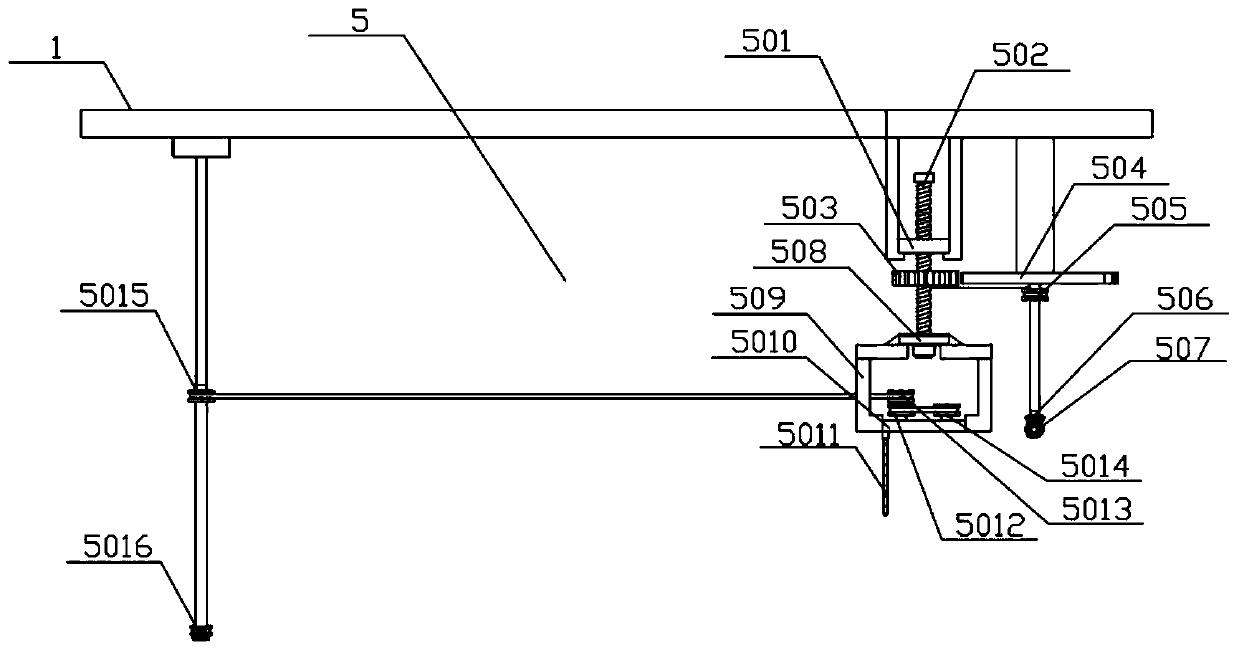

[0031] In this technical solution:

[0032] Welding seam outer surface treatment mechanism-4, fish scale welding weld pattern cooked welding mechanism-5, steel pipe clamping and retarding mechanism-6, fish scale welding weld pool forming mechanism-7, electric slide rail-401, electric slider-402, bolts Elastic device-403, steel pipe weld processing device-404, first electric push rod-405, second electric push rod-406, first transmission wheel-407, motor-408, first bevel gear-409, second cone Gear-4010, first transmission gear-4011, second transmission gear-4012, third transmission gear-4013, fourth transmission gear-4014, fifth transmission gear-4015, transmission gear support plate-4016, grinding wheel-40401 , Second transmission wheel-40402, universal joint-40403, special-shaped runner-40404, shaking frame-40405, telescopic fitting steel brush-40406, upper fixing hoop-40407, first bolt-40408, second bolt-40409 , Lower fixing hoop-404010, first gear rod-404011, internal threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com