Capacitive elastic strain sensor, preparation method thereof and application

An elastic strain and capacitive technology, applied in the direction of sensors, chemical instruments and methods, applications, etc., can solve the problems of poor elastic strain, complex process, poor human body fit, etc., achieve low thickness, improve performance stability, and improve reliability. The effect of wearability and comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

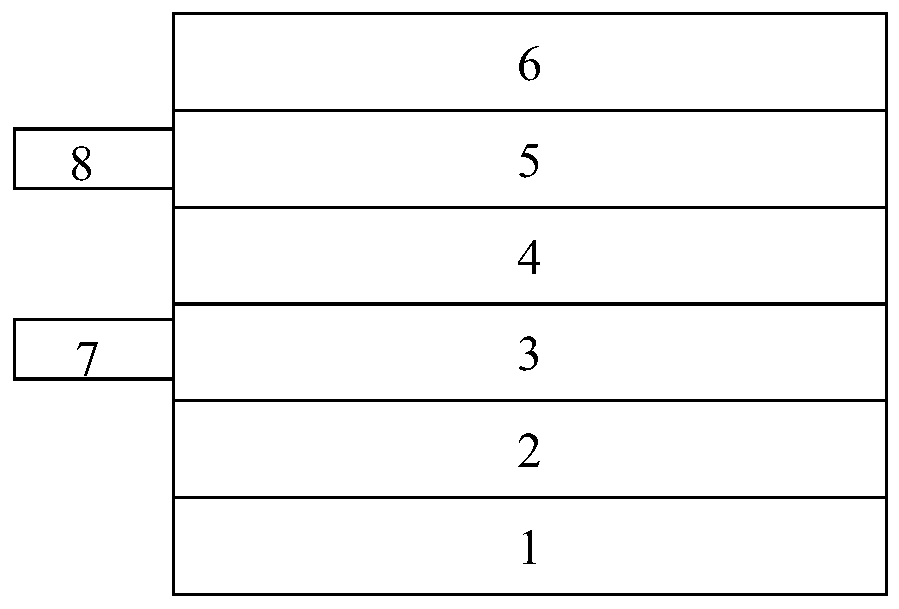

[0047] In this embodiment, the structure of the capacitive elastic strain sensor is as follows figure 1 As shown, the elastic textile material is used as the matrix, and is composed of an elastic bonding layer, a first conductive layer, a second conductive layer, an elastic dielectric layer and an elastic encapsulation layer. The elastic bonding layer is conductive and insulating, and is located on the surface of the substrate; the first conductive layer is located on the surface of the elastic body bonding layer, is composed of liquid metal, and is connected to the first external electrode; the elastic dielectric layer is conductive and insulating, and is located on the surface of the first conductive layer ; The second conductive layer is located on the surface of the elastic dielectric layer, is composed of liquid metal, and is connected to the second external electrode; the elastic encapsulation layer is used to encapsulate the first conductive layer and the second conducti...

Embodiment 2

[0061] In this embodiment, the structure of the capacitive elastic strain sensor is the same as that in Embodiment 1, the difference is that the first conductive layer is in a parallel sinusoidal pattern on the surface of the elastic adhesive layer, and the second conductive layer is in a sinusoidal pattern on the surface of the elastic dielectric layer. Parallel sinusoidal graphs.

[0062] In this embodiment, the preparation of the capacitive elastic strain sensor includes the following steps:

[0063] (1) adopt hot pressing process to form elastic adhesive layer on elastic textile material;

[0064] (2) Place a hollow template on the surface of the elastic adhesive layer; then, fill the template with liquid metal GaInSn by printing; then, remove the template material to obtain the first conductive layer in a juxtaposed sinusoidal pattern;

[0065] (3) the two ends of the liquid metal in each of the sinusoidal patterns obtained in step (2) are pasted with thin copper sheets ...

Embodiment 3

[0072] In this embodiment, the structure of the capacitive elastic strain sensor is as follows figure 1 As shown, the elastic textile material is used as the matrix, and is composed of an elastic bonding layer, a first conductive layer, a second conductive layer, an elastic dielectric layer and an elastic encapsulation layer. The elastic bonding layer is conductive and insulating, and is located on the surface of the substrate; the first conductive layer is located on the surface of the elastic body bonding layer, is composed of liquid metal, and is connected to the first external electrode; the elastic dielectric layer is conductive and insulating, and is located on the surface of the first conductive layer ; The second conductive layer is located on the surface of the elastic dielectric layer, is composed of liquid metal, and is connected to the second external electrode; the elastic encapsulation layer is used to encapsulate the first conductive layer and the second conducti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com