Filling liquid for stabilizing adsorption performance of adsorbent and application thereof

A technology of adsorption performance and adsorbent, which is applied in the direction of selective adsorption, other chemical processes, ion exchange, etc., can solve the problems of unstabilized adsorption performance of adsorbent, loss of adsorption performance, and decrease of adsorption efficiency, so as to achieve excellent effect and adsorption The effect of reducing the performance degradation rate and improving the adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

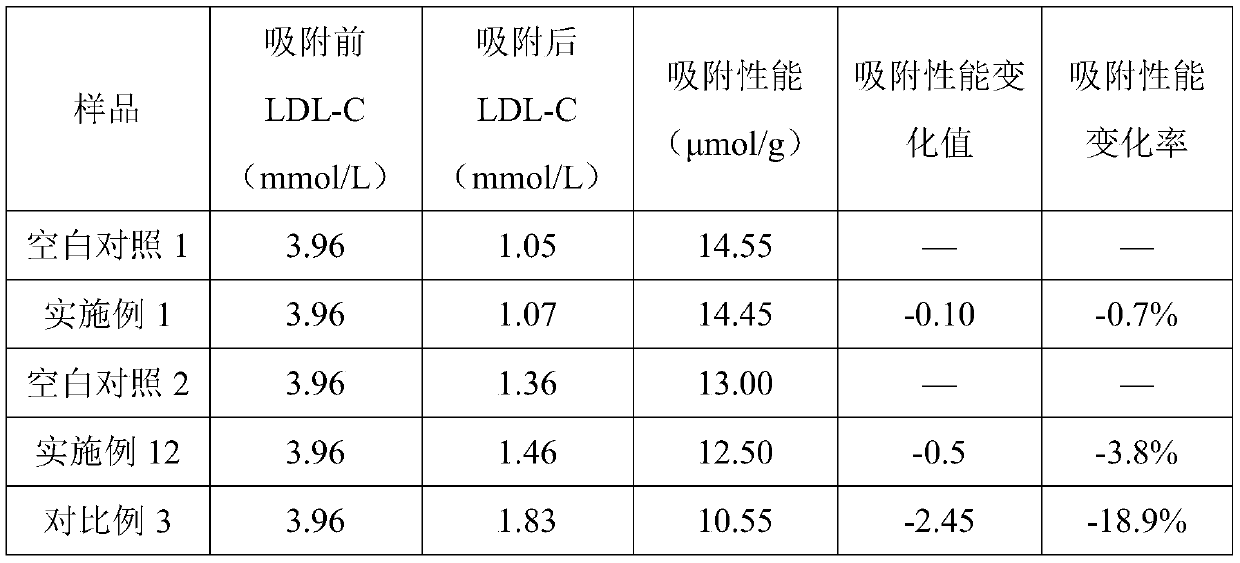

Embodiment 1

[0019] A filling solution for stabilizing the adsorption performance of the adsorbent, consisting of dextran 40 and phosphate buffer, wherein the mass-to-volume ratio of the amount of dextran 40 added to the phosphate buffer is 0.8g:100mL, the phosphate buffer The pH is 6.5.

[0020] The selected adsorbent is a low-density lipoprotein adsorbent whose ligand is dextran sulfate. After the adsorbent is soaked in the above-mentioned filling solution and sealed, it is sterilized by high-pressure steam. The sterilization conditions under pressure are 121°C and 30min. The adsorbent before and after sterilization was taken, washed with water and dried, and the low-density lipoprotein content was detected with a low-density lipoprotein cholesterol detection kit, and the adsorption performance was calculated.

Embodiment 2

[0022] A filling solution for stabilizing the adsorption performance of the adsorbent, consisting of dextran 70 and phosphate buffer, wherein the mass volume ratio of the amount of dextran 70 added to the phosphate buffer is 0.8g:100mL, the phosphate buffer The pH is 6.5.

[0023] The selected adsorbent is a low-density lipoprotein adsorbent whose ligand is dextran sulfate. After the adsorbent is soaked in the above-mentioned filling solution and sealed, it is sterilized by high-pressure steam. The sterilization conditions under pressure are 121°C and 30min. The adsorbent before and after sterilization was taken, washed with water and dried, and the low-density lipoprotein content was detected with a low-density lipoprotein cholesterol detection kit, and the adsorption performance was calculated.

Embodiment 3

[0025] A filling solution for stabilizing the adsorption performance of the adsorbent, consisting of dextran 20 and phosphate buffer, wherein the mass volume ratio of the amount of dextran 20 added to the phosphate buffer is 0.8g:100mL, the phosphate buffer The pH is 6.5.

[0026] The selected adsorbent is a low-density lipoprotein adsorbent whose ligand is dextran sulfate. After the adsorbent is soaked in the above-mentioned filling solution and sealed, it is sterilized by high-pressure steam. The sterilization conditions under pressure are 121°C and 30min. The adsorbent before and after sterilization was taken, washed with water and dried, and the low-density lipoprotein content was detected with a low-density lipoprotein cholesterol detection kit, and the adsorption performance was calculated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com