Suspension system with energy recovery device

An energy recovery device and suspension system technology, which is applied to power plants, jet propulsion devices, internal combustion propulsion devices, etc., can solve the problems of difficulty in popularization and utilization, no recovery, and reduced vibration energy recovery efficiency, so as to improve energy recovery and utilization. Efficiency, reducing energy loss, and facilitating post-maintenance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

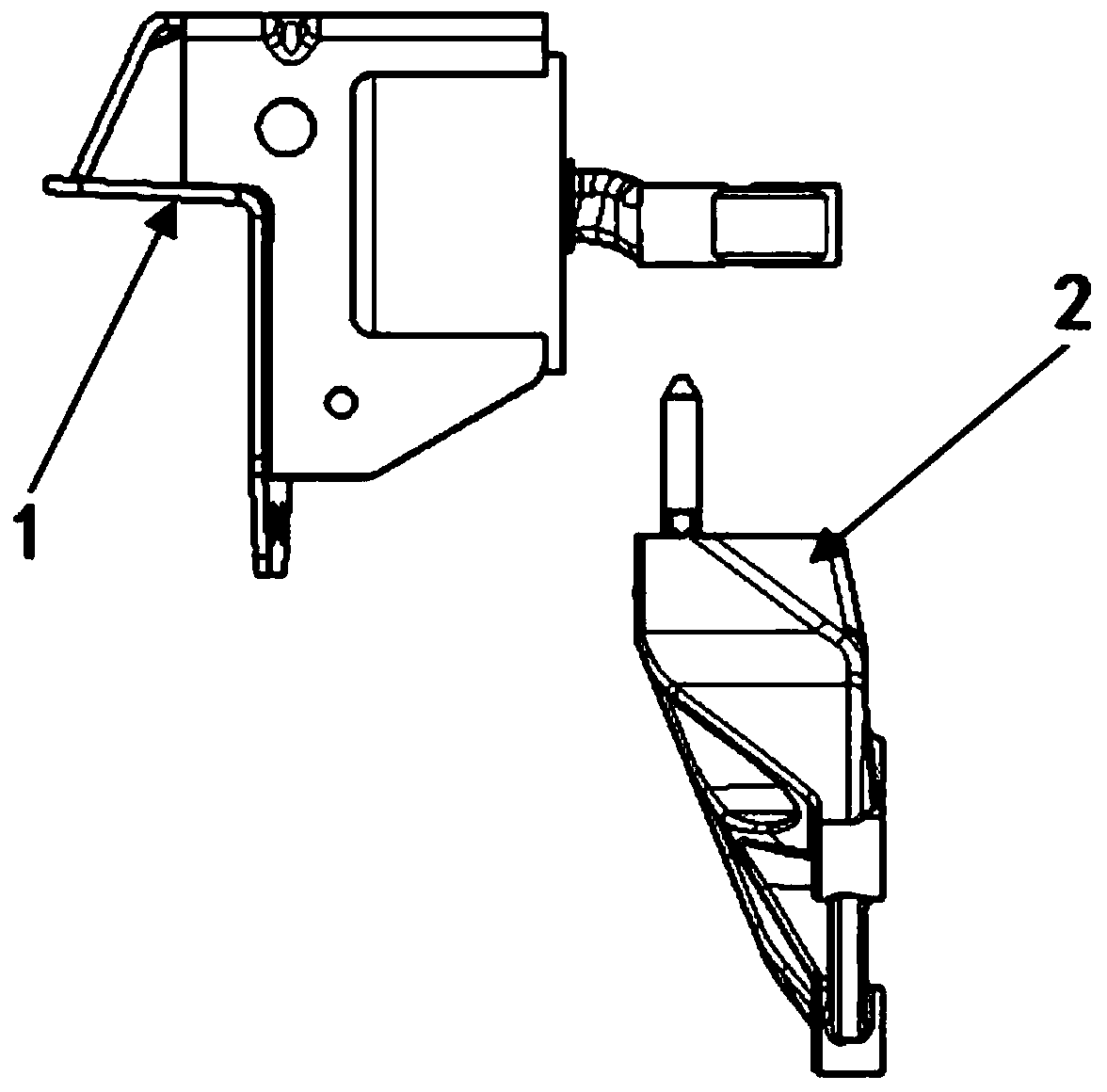

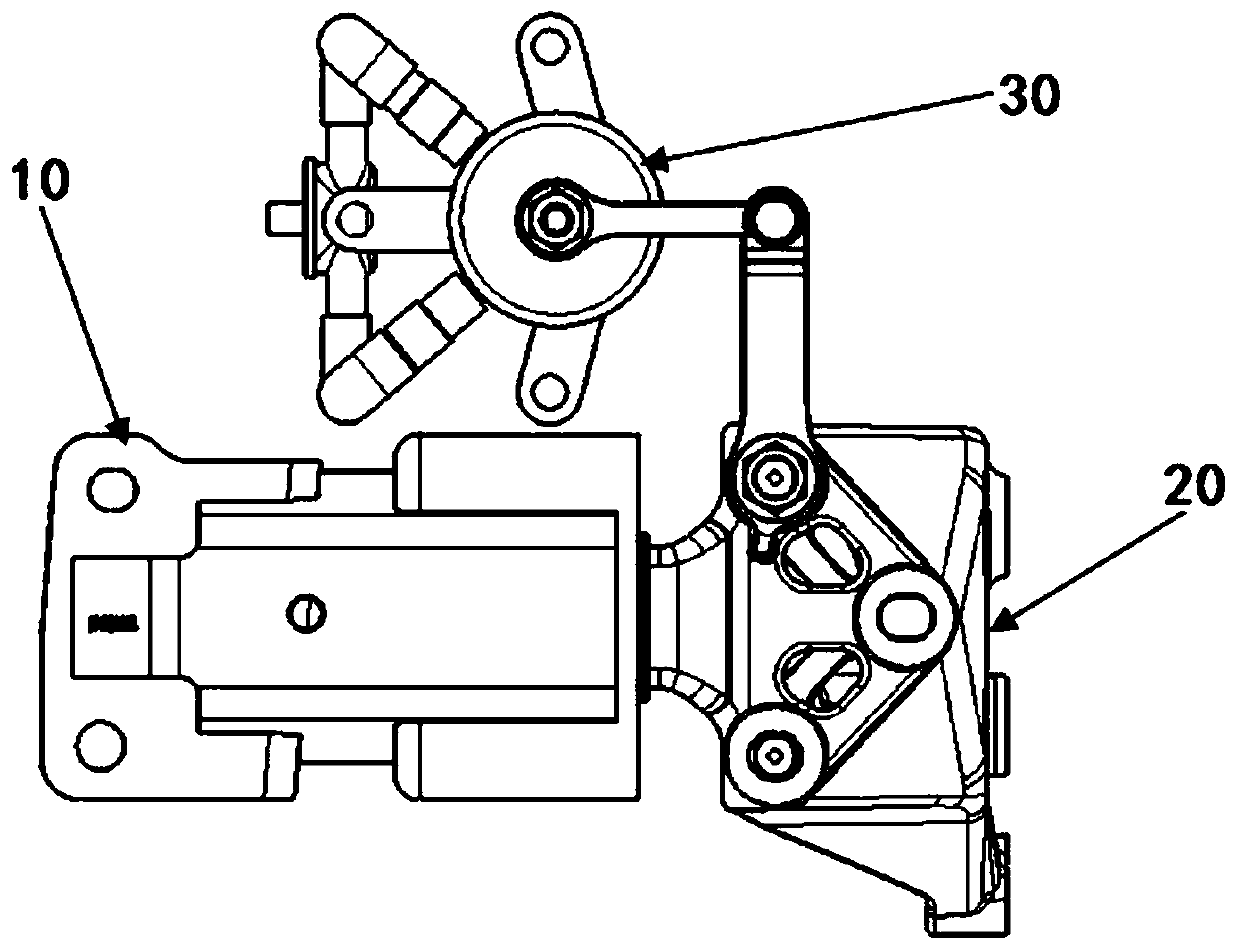

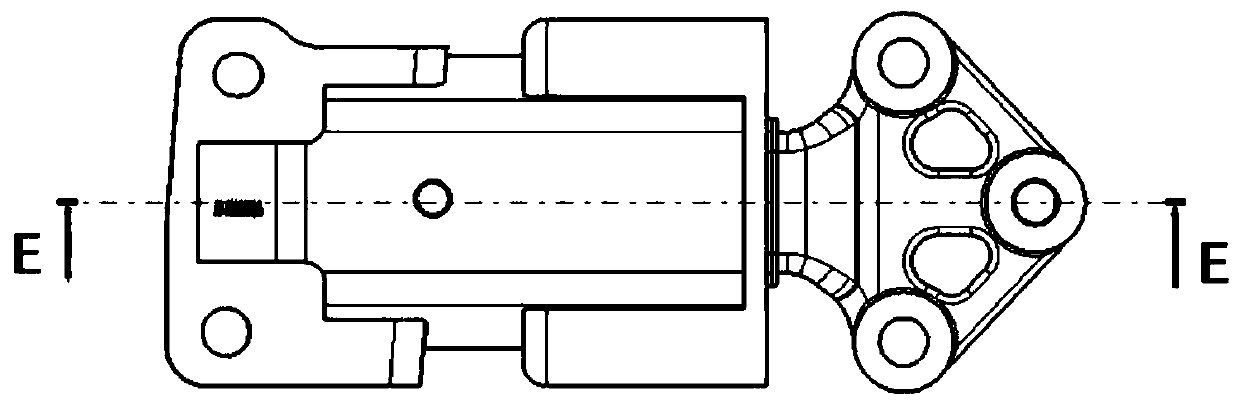

[0036] In order to convert the irregular motion of the power assembly into one-way reciprocating motion, reduce vibration and noise, perform energy recovery, and reduce energy waste, this embodiment provides a method such as Figure 2-14 The suspension system shown includes a suspension cushion 10 and a suspension bracket 20, the suspension cushion 10 is arranged on the powertrain (not shown in the figure), and the suspension bracket 20 is connected with the suspension bracket 20 The suspension cushion 10 is connected, and the suspension bracket 20 is provided with an energy recovery device 30 .

[0037] like Figure 3-4 As shown, the suspension cushion 10 includes an upper bracket 13 and a lower bracket 11, an outer casing 12 is arranged between the upper bracket 13 and the lower bracket 11, and a horizontal bracket 16 is arranged in the middle of the outer casing 12, The outer end of the horizontal support 16 protrudes from the outer casing 12, and the inner end of the hori...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap