Paint viscosity breaker and preparation method thereof

A technology for debonding and painting, applied in the field of environmental pollution control, can solve the problems of insignificant debonding, low slagging efficiency, poor flocculation effect, etc., and achieve the effects of good debonding effect, convenient salvage, and convenient storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

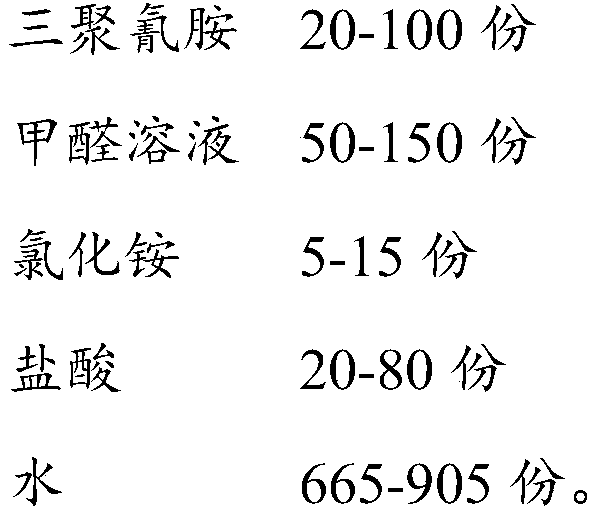

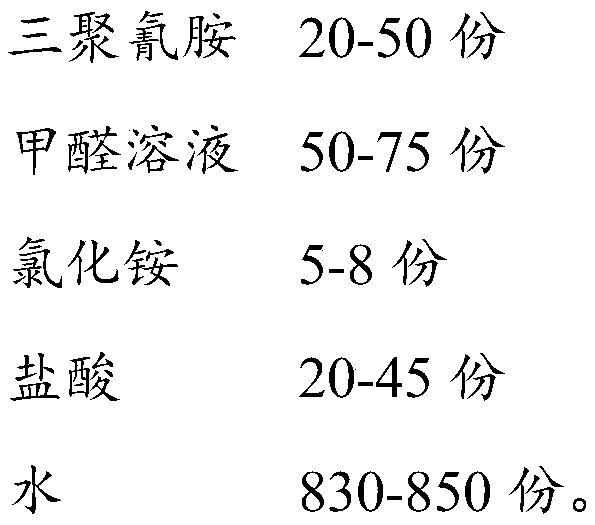

[0025] The raw materials of the paint breaker are: melamine 20kg, formaldehyde solution (concentration is 35%) 50kg, ammonium chloride 5kg, hydrochloric acid (concentration is 30%) 20kg, water 850kg.

[0026] The preparation method of above-mentioned raw material, comprises the following steps: (1) take each raw material according to the parts by weight of above-mentioned raw material, set aside;

[0027] (2) Add raw material water in the reaction kettle to heat up and stir, heat up to 35°C, add melamine and continue stirring for 30 minutes; heat up to 40°C, add formaldehyde solution and ammonium chloride, and keep the temperature at 40°C for 120 minutes until the solution is transparent, stop heating And add hydrochloric acid to react for 300min. After the reaction is completed, a paint breaker with a pH of 1.5-3 is obtained, and the temperature is lowered to 20°C for storage.

Embodiment 2

[0029] The raw materials of the paint breaker are: melamine 100kg, formaldehyde solution (concentration is 38%) 150kg, ammonium chloride 15kg, hydrochloric acid (concentration is 36%) 80kg, water 665kg.

[0030] The preparation method of above-mentioned raw material, comprises the following steps: (1) take each raw material according to the parts by weight of above-mentioned raw material, set aside;

[0031] (3) Add raw material water in the reaction kettle to heat up and stir, heat up to 55°C, add melamine and continue stirring for 30 minutes; heat up to 80°C, add formaldehyde solution and ammonium chloride, and keep the temperature at 80°C for 40 minutes until the solution is transparent, stop heating And add hydrochloric acid to react for 100 minutes. After the reaction is completed, a paint breaker with a pH of 1.5-2 is obtained, and the temperature is lowered to 20°C for storage.

Embodiment 3

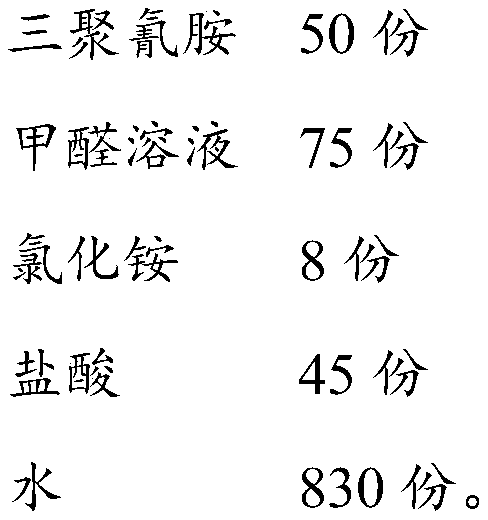

[0033] The raw materials of the paint breaker are: melamine 50kg, formaldehyde solution (concentration is 38%) 75kg, ammonium chloride 8kg, hydrochloric acid (concentration is 36%) 45kg, water 822kg.

[0034] The preparation method of above-mentioned raw material, comprises the following steps: (1) takes each raw material according to the parts by weight of above-mentioned raw material;

[0035] (2) Add raw material water in the reaction kettle to heat up and stir, heat up to 40°C, add melamine and continue stirring for 30 minutes; heat up to 60°C, add formaldehyde solution and ammonium chloride, and keep the temperature at 60°C for 60 minutes until the solution is transparent, stop heating And add hydrochloric acid to react for 180min. After the reaction is completed, a paint breaker with a pH of 1.5-2 is obtained, and the temperature is lowered to 20°C for storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com