A kind of low-gloss body matting water-based polyurethane resin and preparation method thereof

A water-based polyurethane, matting technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of synthetic leather matte surface treatment agent easy to drop powder, hand feeling additives easy to precipitate, poor leveling, etc., to achieve Save manpower and equipment costs, improve storage stability, and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

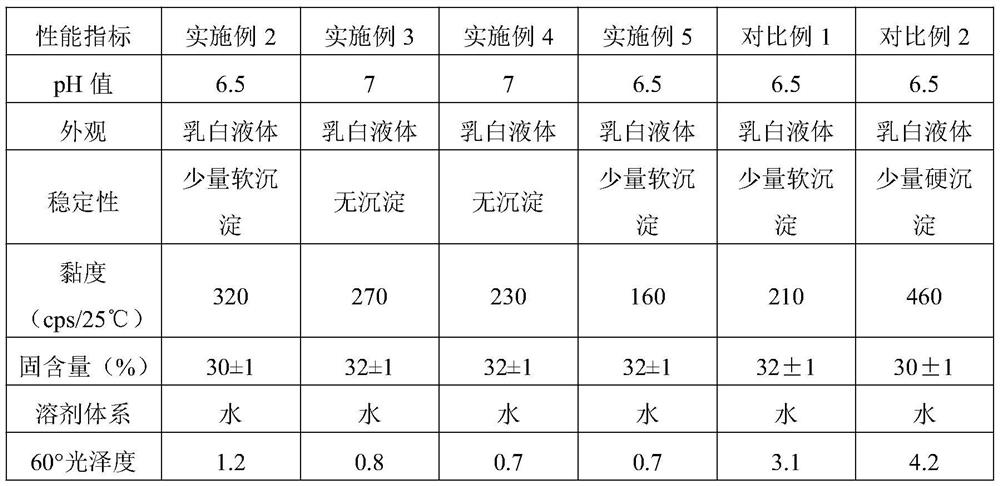

Examples

Embodiment 1

[0043] A low-gloss body matting water-based polyurethane resin, made of the following raw materials in parts by weight: 30-70 parts of polymerized polyol, 5-15 parts of self-made sulfonate-type polymerized polyol, 0-10 parts of polyether modified silicone oil 2-8 parts of hydrophilic chain extender, 15-45 parts of isocyanate, 1-5 parts of crosslinking agent, 1-5 parts of diol chain extender, and 2-8 parts of diamine chain extender.

[0044] Preferably, the low-gloss body matting water-based polyurethane resin is made of the following raw materials in parts by weight: 45-65 parts of polymerized polyol, 7-12 parts of self-made sulfonate-type polymerized polyol, 5 parts of polyether-modified silicone oil ~8 parts, 3-5 parts of hydrophilic chain extender, 25-35 parts of isocyanate, 1-3 parts of crosslinking agent, 3-5 parts of diol chain extender, and 2-6 parts of diamine chain extender.

[0045]Preferably, the polymer polyol is polyester type polyethylene adipate diol (PEA), poly...

Embodiment 2

[0068] Add 28 parts of PNA 2000, 14 parts of PTMG 1000, 5 parts of self-made sulfonate polymer polyol, 3 parts of polyether modified silicone oil 1000, 7 parts of PEG 1000, and 3 parts of MPEG 750 into a four-necked flask for 110~ Dehydration under reduced pressure at 120°C for 1 hour; then lower the temperature to about 70°C, add 32 parts of IPDI, then raise the temperature to 85-90°C, add a small amount of organic bismuth catalyst and keep it at this temperature for 2 hours to measure the NCO content; after the NCO content reaches the standard, Cool down to about 50°C, add 2 parts of neopentyl glycol and 1.5 parts of TMP, keep warm at 75-80°C, and measure the NCO content; after the NCO content reaches the standard, add acetone to dilute and reduce the viscosity. IPDA (diluted in acetone first), emulsified and dispersed with deionized water under a high-speed shearing machine, and after it is completely dispersed, add 3 parts of IPDA (diluted in water first) dropwise for post-...

Embodiment 3

[0071] Add 14 parts of PCD2000, 14 parts of PTMG1000, 5 parts of self-made sulfonate polymer polyol, 5 parts of polyether modified silicone oil 2000, and 6 parts of YmerN120 into a four-necked flask for dehydration under reduced pressure at 110-120°C for 1 hour; then lower the temperature to At about 70°C, add 25 parts of IPDI and 10 parts of HDI, then raise the temperature to 80-90°C, add a small amount of organic bismuth catalyst and keep it warm at this temperature for 2 hours to measure the NCO content; after the NCO content reaches the standard, cool down to about 50°C, Add 2 parts of BDO and 1 part of TMP, keep warm at 75-80°C, and measure the NCO content; after the NCO content reaches the standard, add acetone to dilute and reduce the viscosity, and at the same time cool down to below 50°C, add 1 part of IPDA dropwise (dilute in acetone first) , emulsify and disperse with deionized water under a high-speed shearing machine, and after it is completely dispersed, add 2.5 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com