Fermentation broth processing method capable of improving final concentration of pullulanase

A pullulanase and treatment method technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, enzymes, etc., can solve the problems that the enzyme concentration cannot be further increased, the viscosity of the pullulanase fermentation broth is high, etc., and achieve improvement Filtration performance, reduction of storage space, effect of increasing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

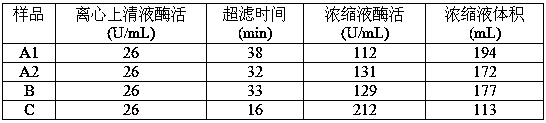

[0021] Embodiment 1: the influence of different processing methods of pullulanase fermented liquid on ultrafiltration concentration

[0022] Take the supernatant of the pullulanase fermentation broth produced by fermentation in a 5 L fermenter, and make four portions of 900 mL each, labeled A1, A2, B, and C, respectively. Add 100 mL of double distilled water to A1 and A2, add 100 mL of 10× citric acid buffer solution to B, and add 100 mL of 10× fermentation broth treatment solution C to C.

[0023] The 10X citric acid buffer added in B contained 200 mM citric acid-sodium citrate, pH 5.4-5.6. The configuration method is: add 800mL deionized water to a 1 L volumetric flask, add citric acid monohydrate ((C 6 h 8 o 7 )·H 2 (2) 12.6 g, sodium citrate monohydrate ((Na 3 C 6 h 5 o 7 )·H 2 (2) 41.2g, if the pH deviates then adjust the pH to 5.5±0.1 with NaOH or HCl, add water to 1 L.

[0024] After mixing, the four mixed solutions are processed as follows:

[0025] A1 was p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com