Obstacle avoidance device of front sweeping brush system

A system installation and sweeping technology, which is applied in road cleaning, construction, cleaning methods, etc., can solve problems such as poor obstacle avoidance ability, affecting cleaning ability, and damage to the front sweeping system, so as to improve durability, stability, and operation safety , The effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and concrete implementation, following embodiment is only a part of embodiment of the present invention, rather than all embodiment, based on the embodiment in the present invention, those of ordinary skill in the art All other embodiments obtained under the premise of no creative work belong to the protection scope of the present invention.

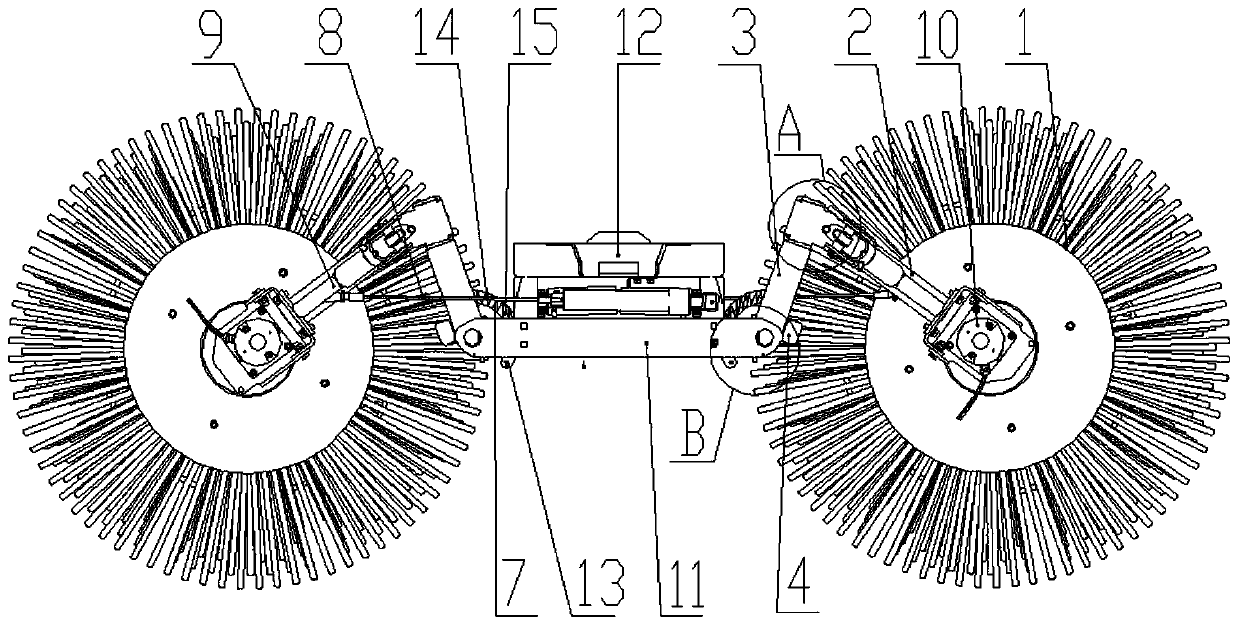

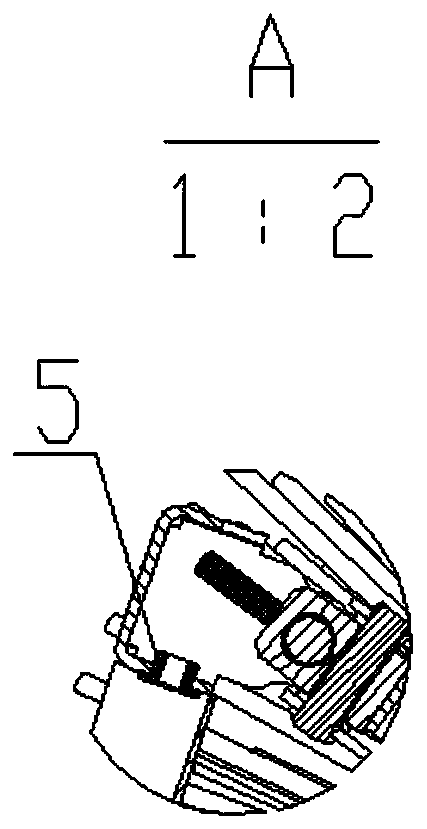

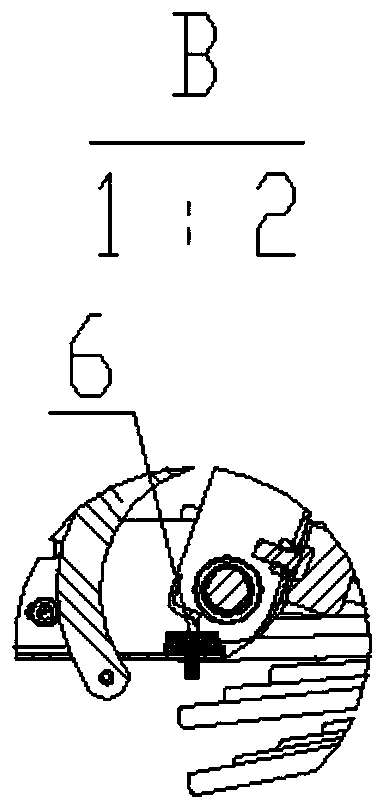

[0030] In the following drawings in the present invention, those with the same numbers have the same descriptions. Among them, 1 is the sweeping brush, 2 is the forearm of the sweeping brush, 3 is the upper arm of the sweeping brush, 4 is the contraction limit block of the forearm brush arm, 5 is the extension limiter of the forearm brush arm, and 6 is the contraction limit of the forearm brush arm. Bit block, 7 is the extension limit device of the sweeping brush arm, 8 is the swing angle control tension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com