Well-sinking vertical tunnelling machine

A technology of roadheader and caisson, which is applied in the direction of earth mover/shovel, construction, etc., can solve the problems of pollution, uneven settlement of caisson, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

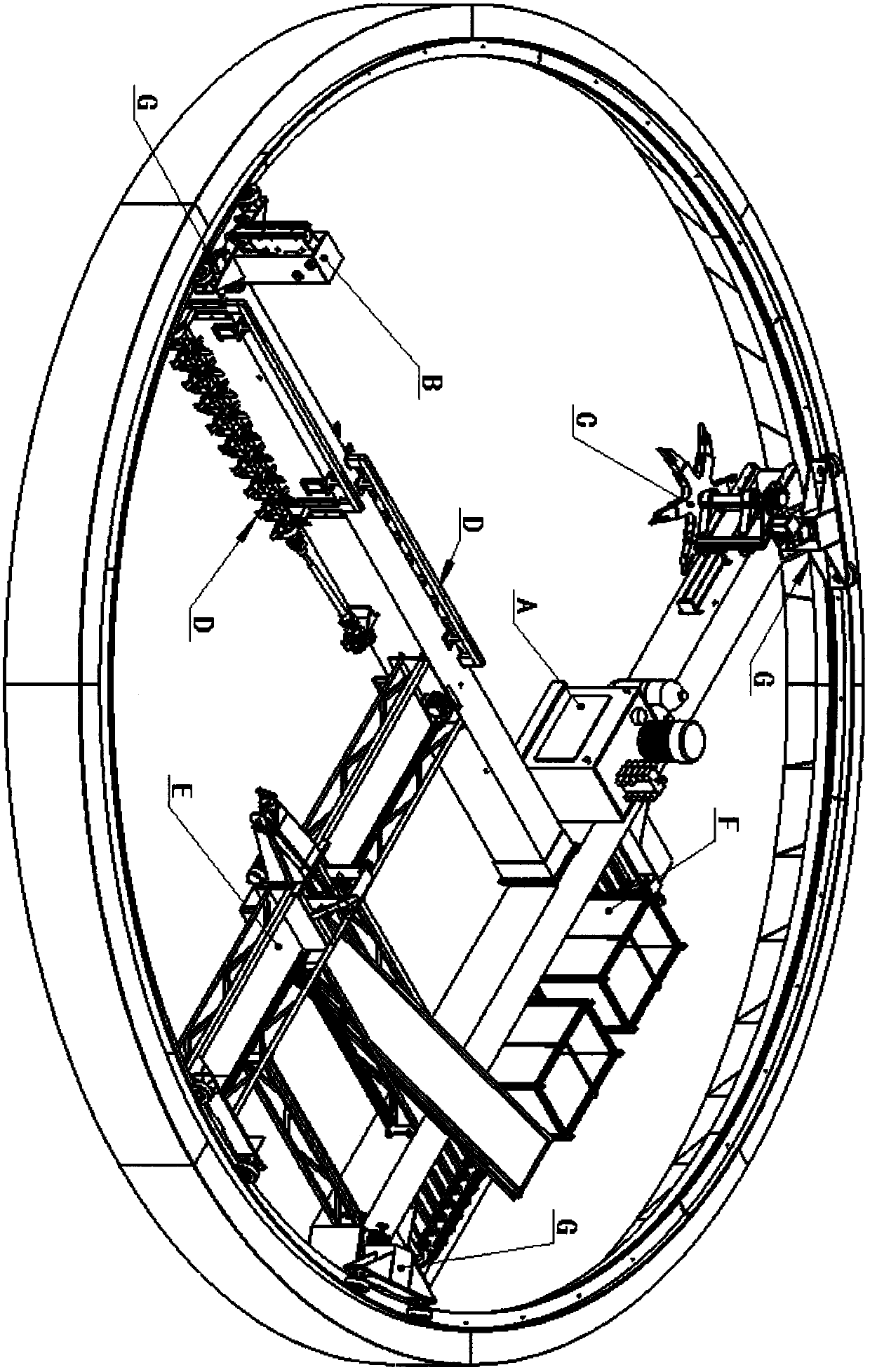

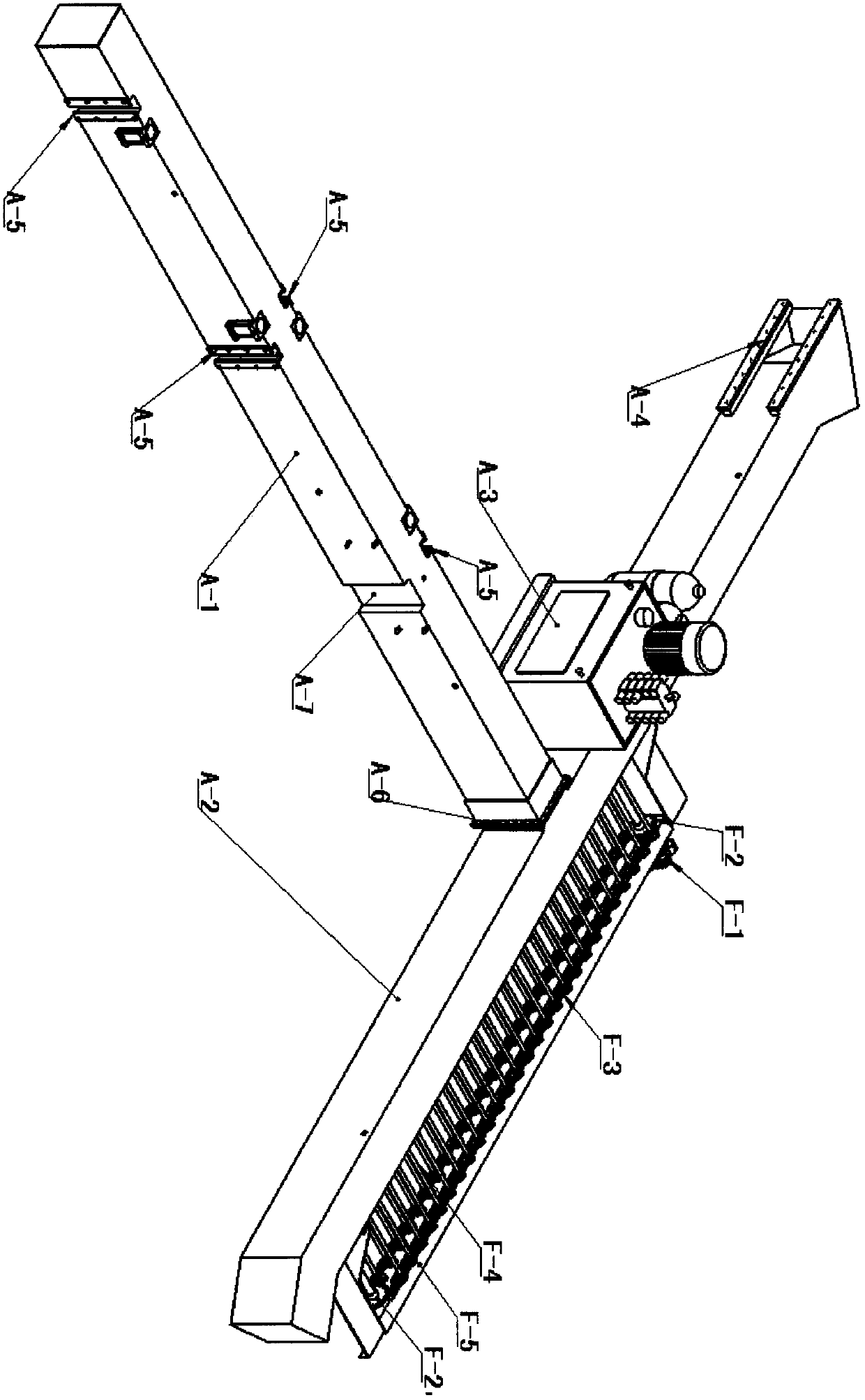

[0030] The main structure welded with steel plates, including; longitudinal steel box girder (A-1), horizontal steel box girder (A-2), left and right hob milling cutters (D) are installed on the longitudinal steel box girder, and Nitrogen hydraulic impact hammer (B) and walking power system (G) are installed, hydraulic station (A), disc milling cutter (C) and walking power system (G) are installed on the horizontal steel box girder, and the horizontal steel box girder is additionally One side is equipped with a muck box transfer chain row (F).

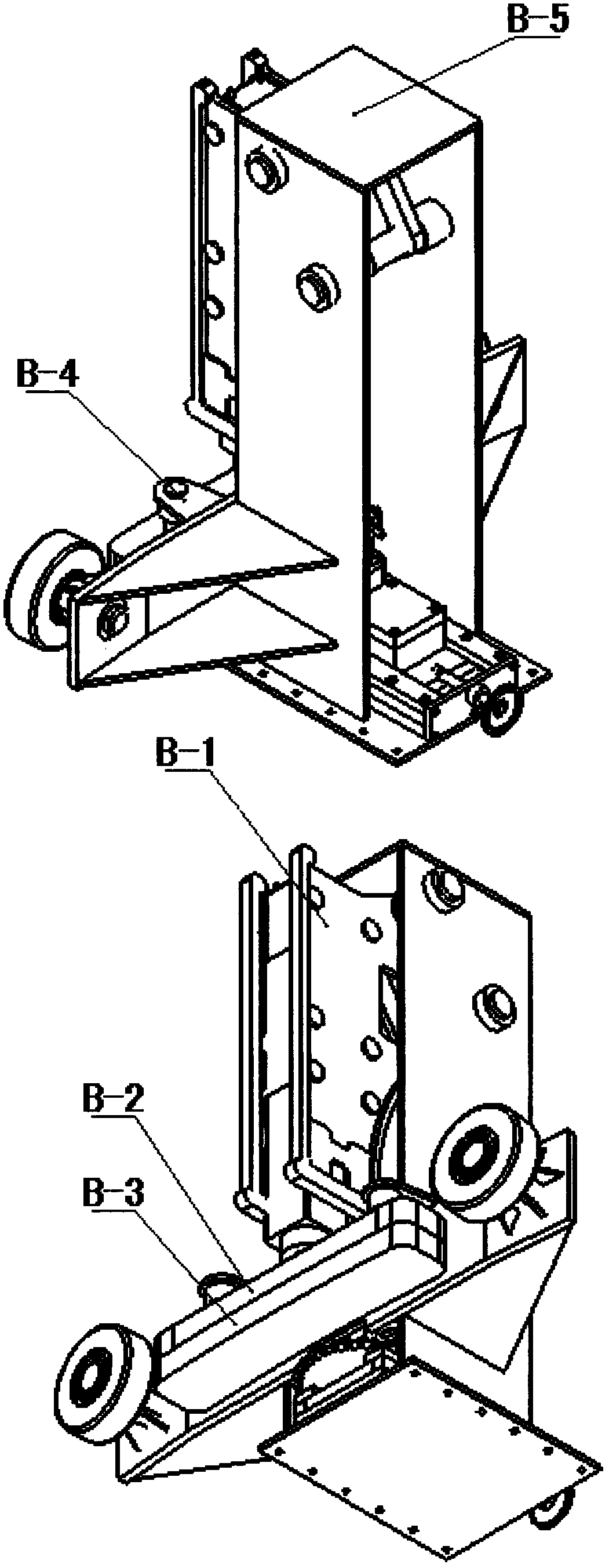

[0031] The construction deviation correcting system of the present invention adopts a general-purpose nitrogen gas hydraulic impact hammer for an excavator. (B-1) The nitrogen gas hydraulic impact hammer is installed on the end of the longitudinal steel box girder, but the impact head is replaced by a rubber pad (B-3) Vibration block (B-2) If there is a deviation in the horizontal state of the blade foot steel enclosure during the cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com