Electromagnetic self-balance dry-friction damper with elastic bearing and used for rotor bearing structure of rotary machine

A technology of dry friction damper and elastic support, which is applied in the direction of mechanical equipment, rotation vibration suppression, spring/shock absorber, etc. It can solve the problem of inability to work in high temperature environment, complex structure of dry friction damper, and small friction adjustment range and other problems, to achieve the effect of small axial size of the structure, meeting the requirements of vibration and stability control, and a wide range of changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

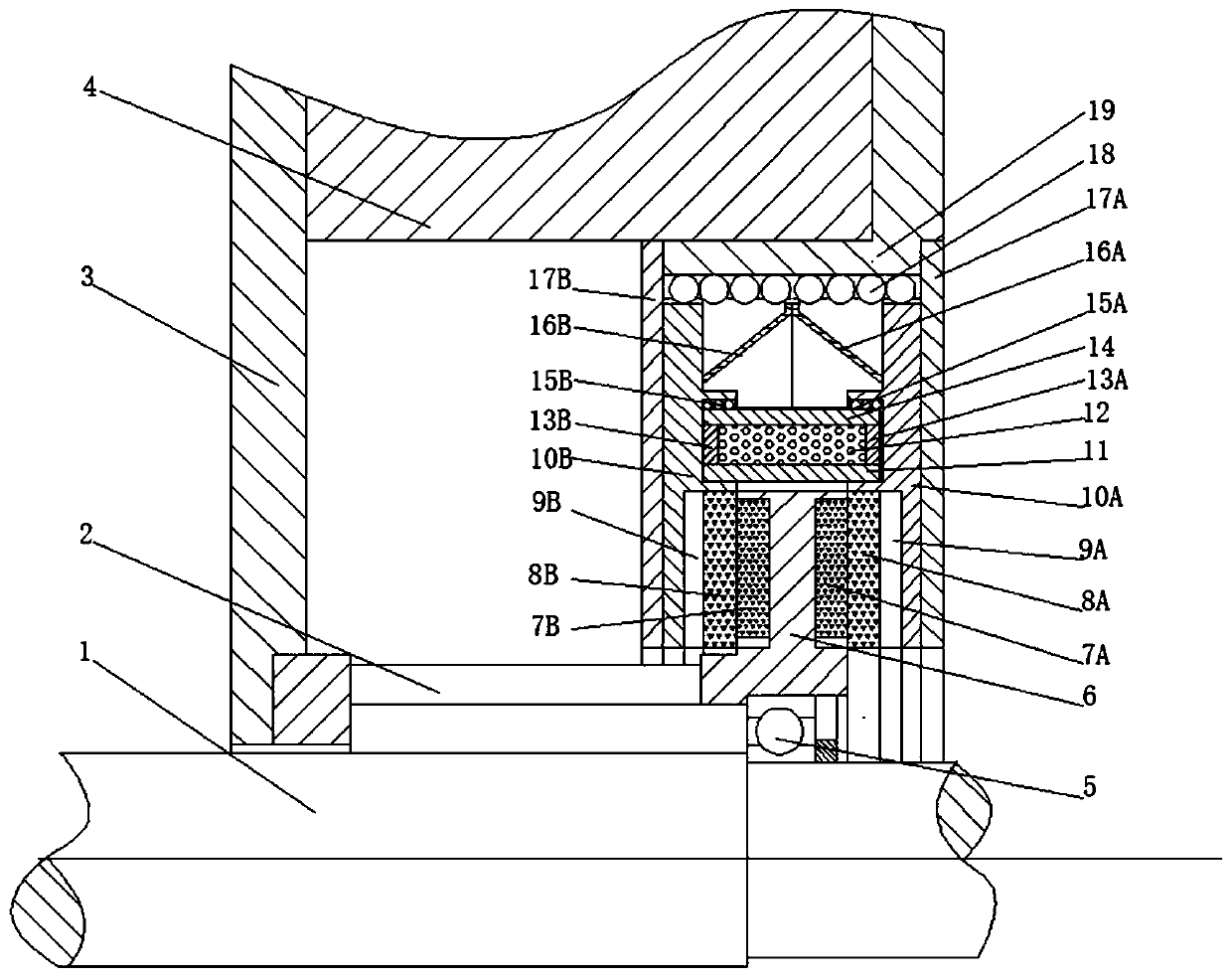

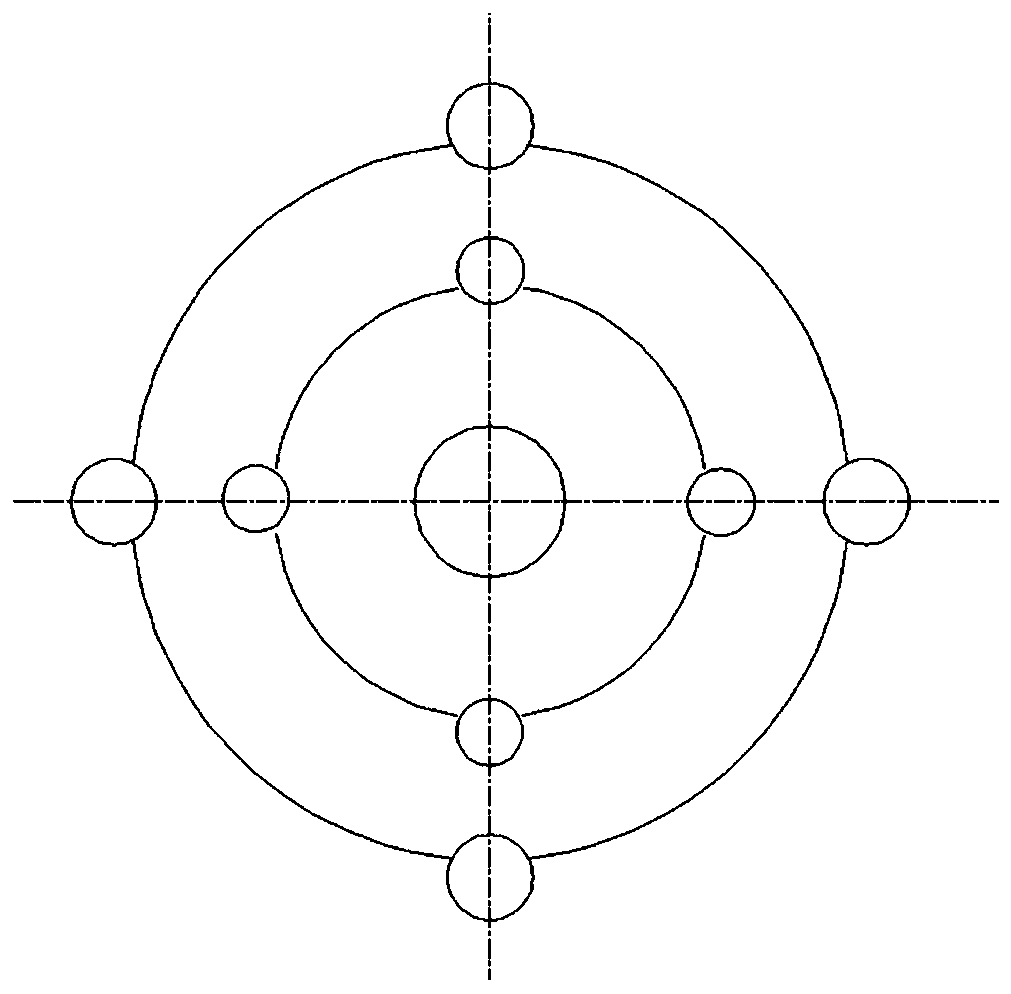

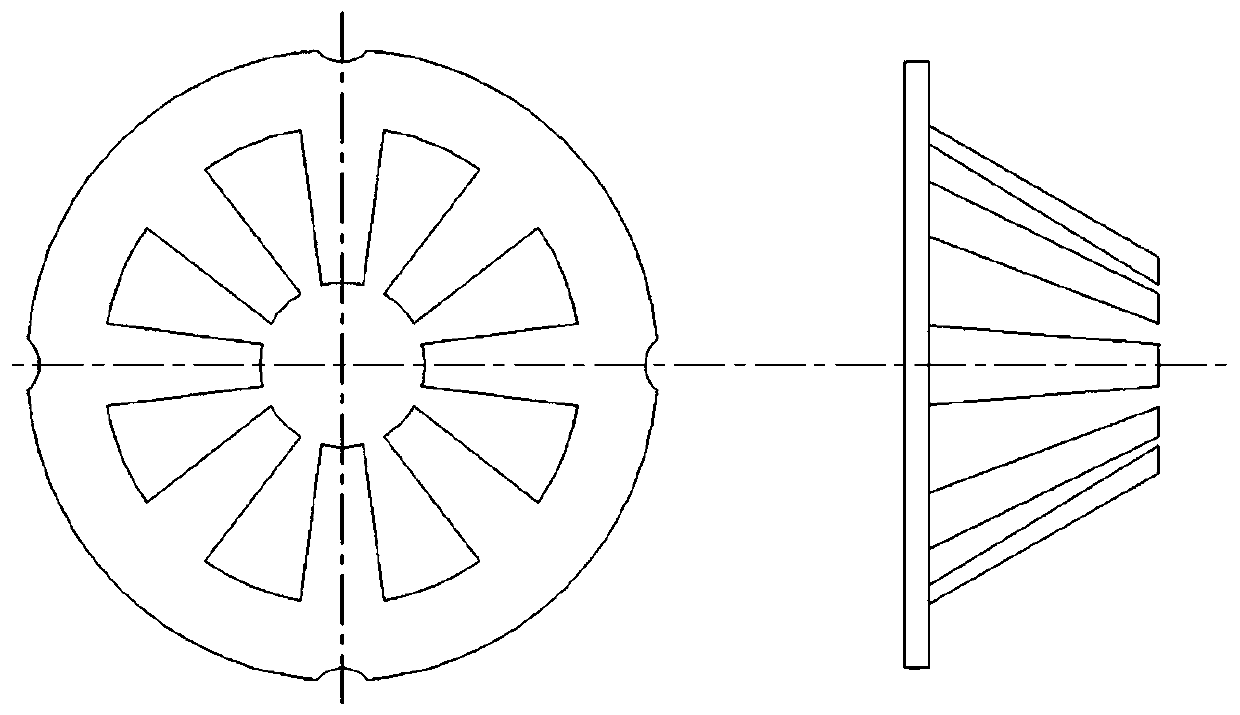

[0021] Such as figure 1 As shown, the electromagnetic self-balancing elastic support dry friction damper of a rotating machinery rotor support structure provided by the present invention includes a rotating shaft 1; an elastic support 2; an elastic support bracket 3; a bearing seat 4; a bearing 5; Right dynamic friction plate 7A; Left dynamic friction plate 7B; Right static friction plate 8A; Left static friction plate 8B; Right force sensor 9A; Left force sensor 9B; Right static friction plate support 10A; Coil 12; right coil support 13A; left coil support 13B; electromagnet outer magnetic ring 14; right inner positioning ball 15A; left inner positioning ball 15B; right axial preload butterfly spring 16A; left axial preload butterfly spring 16B; right preload adjustment plate 17A; left preload adjustment plate 17B; outer position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com