Open-type lithium bromide unit for synchronous cooling and heating

A lithium bromide unit, refrigeration and heating technology, which is applied in the field of lithium bromide units, can solve the problems of high airtightness requirements of lithium bromide units, complex processes of lithium bromide units, and high manufacturing costs, and achieves the advantages of reducing airtight requirements, improving vacuum degree, and improving energy-saving efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

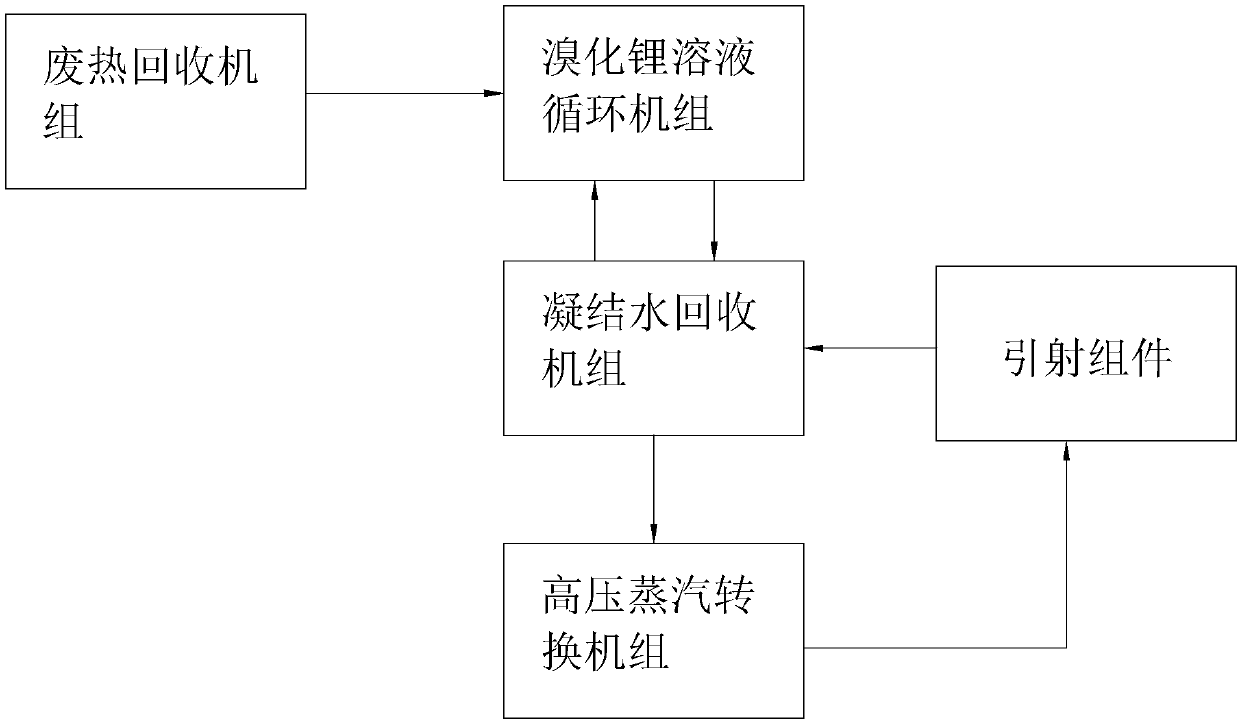

[0041] Example: An open-type lithium bromide unit with synchronous cooling and heating, such as figure 1 As shown, it includes a lithium bromide solution circulation unit used for refrigeration, a waste heat recovery unit used to recover waste heat and used in a lithium bromide solution circulation unit, a condensate recovery unit used to recover steam condensate, and a flash tank for ejection The ejector components for low-pressure steam, and the high-pressure steam conversion unit for converting steam condensate into high-pressure steam.

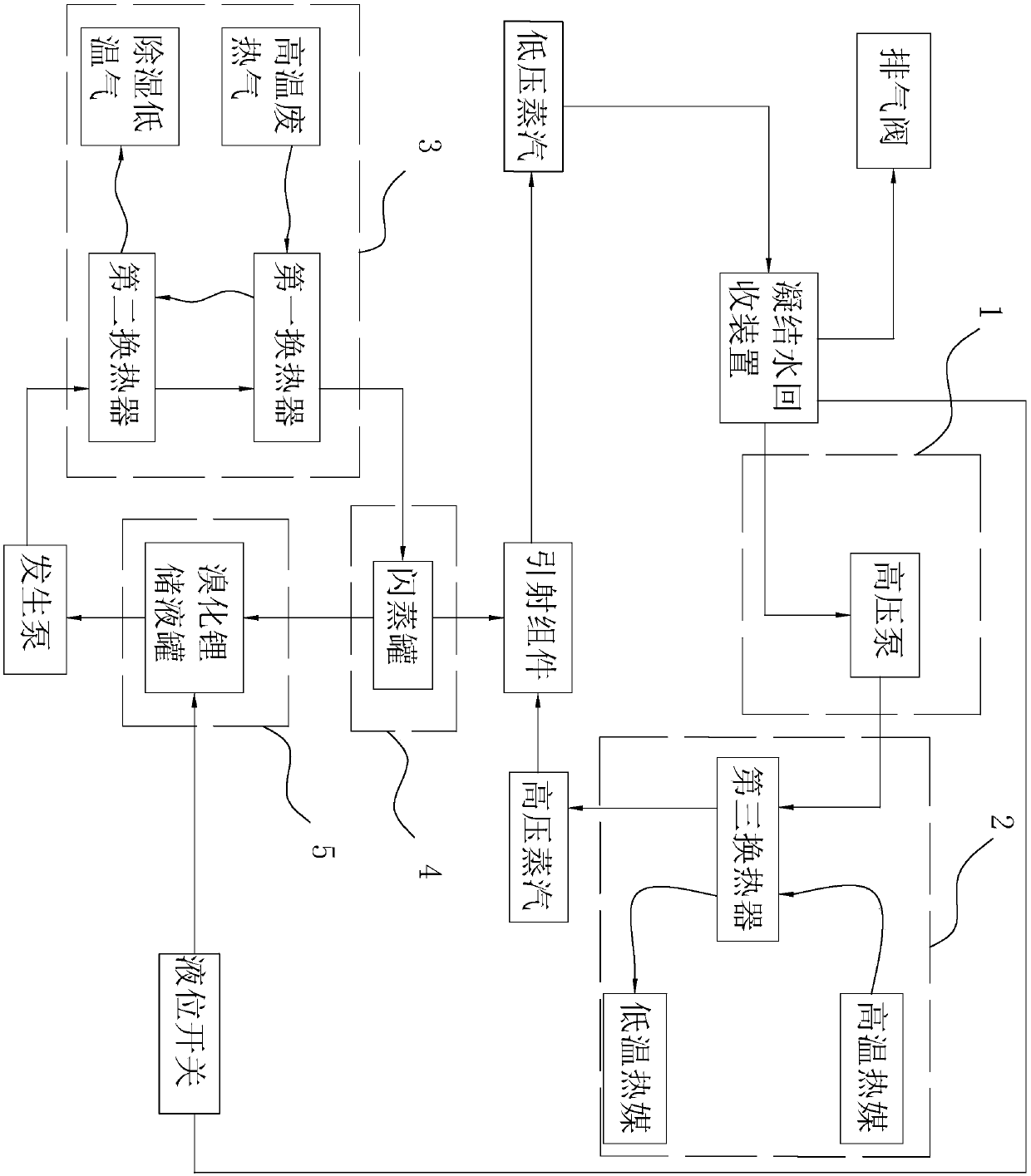

[0042] Reference figure 2 As shown, the lithium bromide solution circulation unit includes a low-pressure flash evaporation device 4 for low-pressure evaporation of the lithium bromide solution, a liquid storage device 5 for storing the lithium bromide solution, a heat exchange component 3 for heating the lithium bromide solution, and a The lithium bromide solution in the device 5 is transferred to the generating pump in the heat exchange as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com