Universality and stability verification method for model specific to frying oil polar component detection

A technology of polar components and verification methods, which is applied in biological neural network models, material excitation analysis, Raman scattering, etc. Unknown and other problems, to achieve the effect of high accuracy and accurate evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The present invention will be described in further detail below in conjunction with the accompanying drawings.

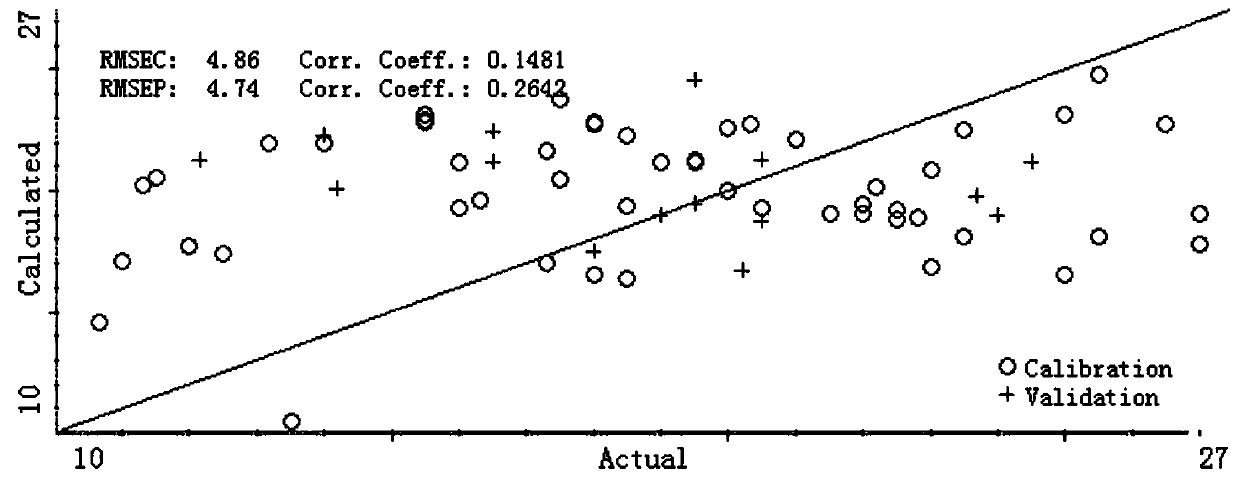

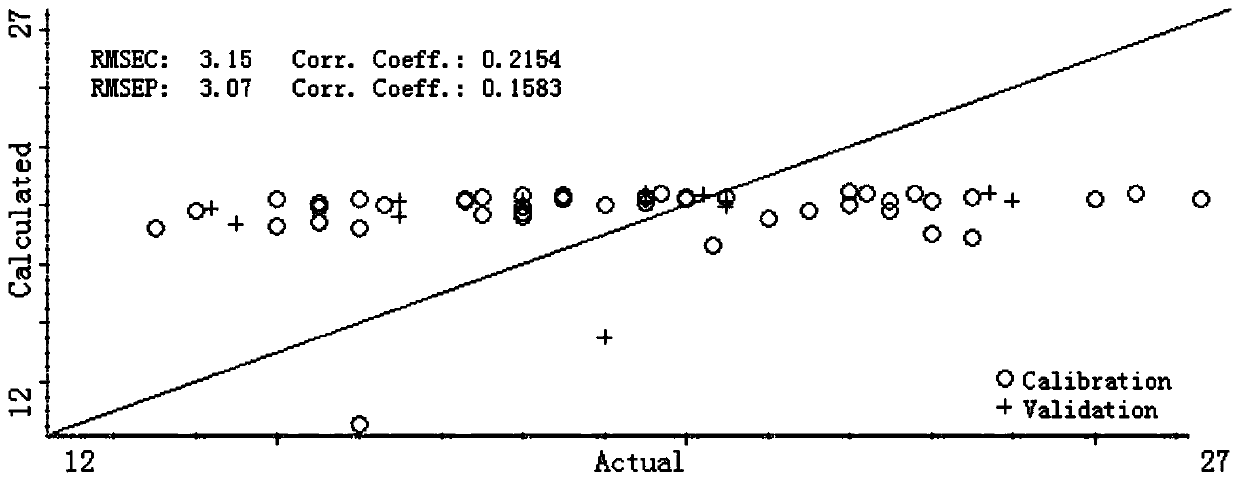

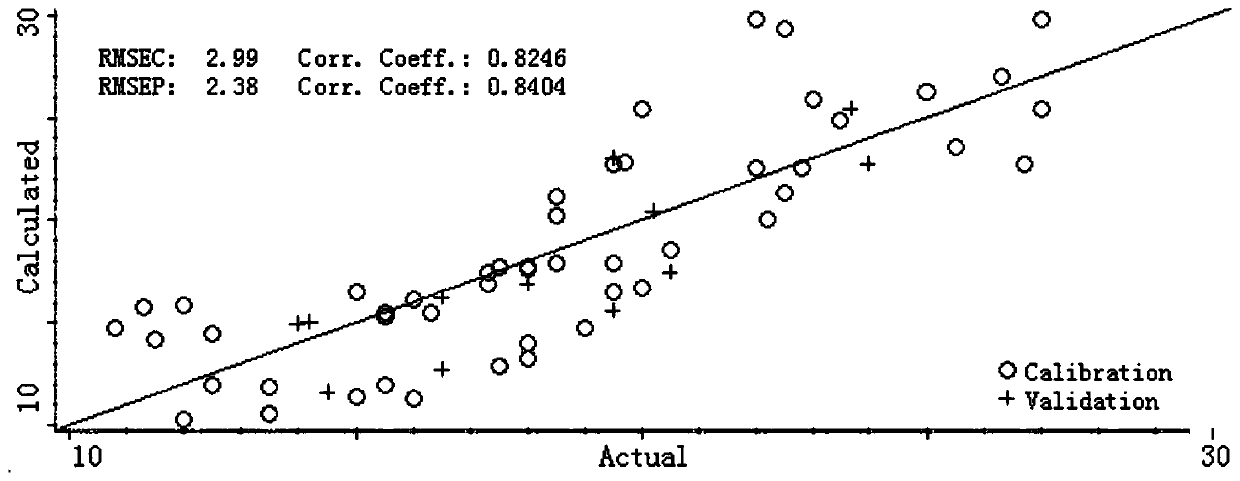

[0076] refer to Figure 45 As shown, it is a model versatility and stability verification method for the detection of frying oil polar components disclosed by the present invention, which includes the following steps:

[0077] Firstly, 83 kinds of oil samples were prepared to fry the same frying objects under the same frying conditions, and samples were collected under the same sampling conditions; among them:

[0078] The 83 kinds of oil samples are all made of cottonseed oil, soybean oil, rapeseed oil and palm oil as raw materials for frying, and are formed by selecting different oil types and ratios.

[0079] The object of frying is quick-frozen French fries.

[0080] The same frying condition is to heat the oil sample to the same oil temperature, fry with the same frying frequency (eg 4 times / hour) and the same single frying time (eg 4min).

[0081] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com