Process for preparing soybean protein isolate with heat stability

A technology of soybean protein isolate and thermal stability, applied in the field of vegetable protein, can solve the problems of destroying nutritional value and affecting taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

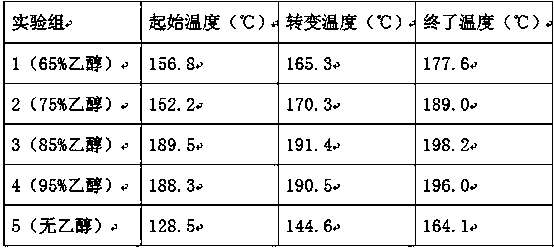

Image

Examples

Embodiment 1

[0026] A preparation process of heat-stable soybean protein isolate, comprising the following steps:

[0027] S1. Take the defatted soybean meal, grind it and pass it through an 80-mesh sieve to obtain the sieve, add 85% ethanol to the sieve according to the mass ratio of 1:4, and leaching for 30 minutes;

[0028] S2, performing solid-liquid separation on the solid-liquid mixture leached from S1 to obtain semi-finished soybean meal;

[0029] S3. Washing the semi-finished soybean meal obtained in S2, and then separating the solid from the liquid. The obtained solid is suction-filtered into a cake shape, and dried naturally to obtain alcohol-modified soybean meal;

[0030] S4, crushing the alcohol-modified soybean meal and passing it through an 80-mesh sieve, extracting with alkali solution, centrifuging to obtain supernatant, acid precipitation, centrifuging to obtain curd, pH correction, freeze-drying and crushing to obtain soybean protein isolate;

[0031] S5. Add modified s...

Embodiment 2

[0042] A preparation process of heat-stable soybean protein isolate, comprising the following steps:

[0043] S1. Take the defatted soybean meal, crush it and pass it through an 80-mesh sieve to obtain the sieve, add 95% ethanol to the sieve according to the mass ratio of 1:8, and leaching for 60 minutes;

[0044] S2, performing solid-liquid separation on the solid-liquid mixture leached from S1 to obtain semi-finished soybean meal;

[0045] S3. Washing the semi-finished soybean meal obtained in S2, and then separating the solid from the liquid. The obtained solid is suction-filtered into a cake shape, and dried naturally to obtain alcohol-modified soybean meal;

[0046] S4, crushing the alcohol-modified soybean meal and passing it through an 80-mesh sieve, extracting with alkali solution, centrifuging to obtain supernatant, acid precipitation, centrifuging to obtain curd, pH correction, freeze-drying and crushing to obtain soybean protein isolate;

[0047] S5. Add modified s...

Embodiment 3

[0058] A preparation process of heat-stable soybean protein isolate, comprising the following steps:

[0059] S1. Take the defatted soybean meal, grind it and pass it through an 80-mesh sieve to obtain the sieve, add 90% ethanol to the sieve according to the mass ratio of 1:6, and leaching for 45 minutes;

[0060] S2, performing solid-liquid separation on the solid-liquid mixture leached from S1 to obtain semi-finished soybean meal;

[0061] S3. Washing the semi-finished soybean meal obtained in S2, and then separating the solid from the liquid. The obtained solid is suction-filtered into a cake shape, and dried naturally to obtain alcohol-modified soybean meal;

[0062] S4, crushing the alcohol-modified soybean meal and passing it through an 80-mesh sieve, extracting with alkali solution, centrifuging to obtain supernatant, acid precipitation, centrifuging to obtain curd, pH correction, freeze-drying and crushing to obtain soybean protein isolate;

[0063] S5. Add modified s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com