False tooth 3D printing manufacturing technology and 3D printing device thereof

A 3D printing and manufacturing process technology, applied in the field of 3D printing, can solve the problems of unable to scan and establish denture models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

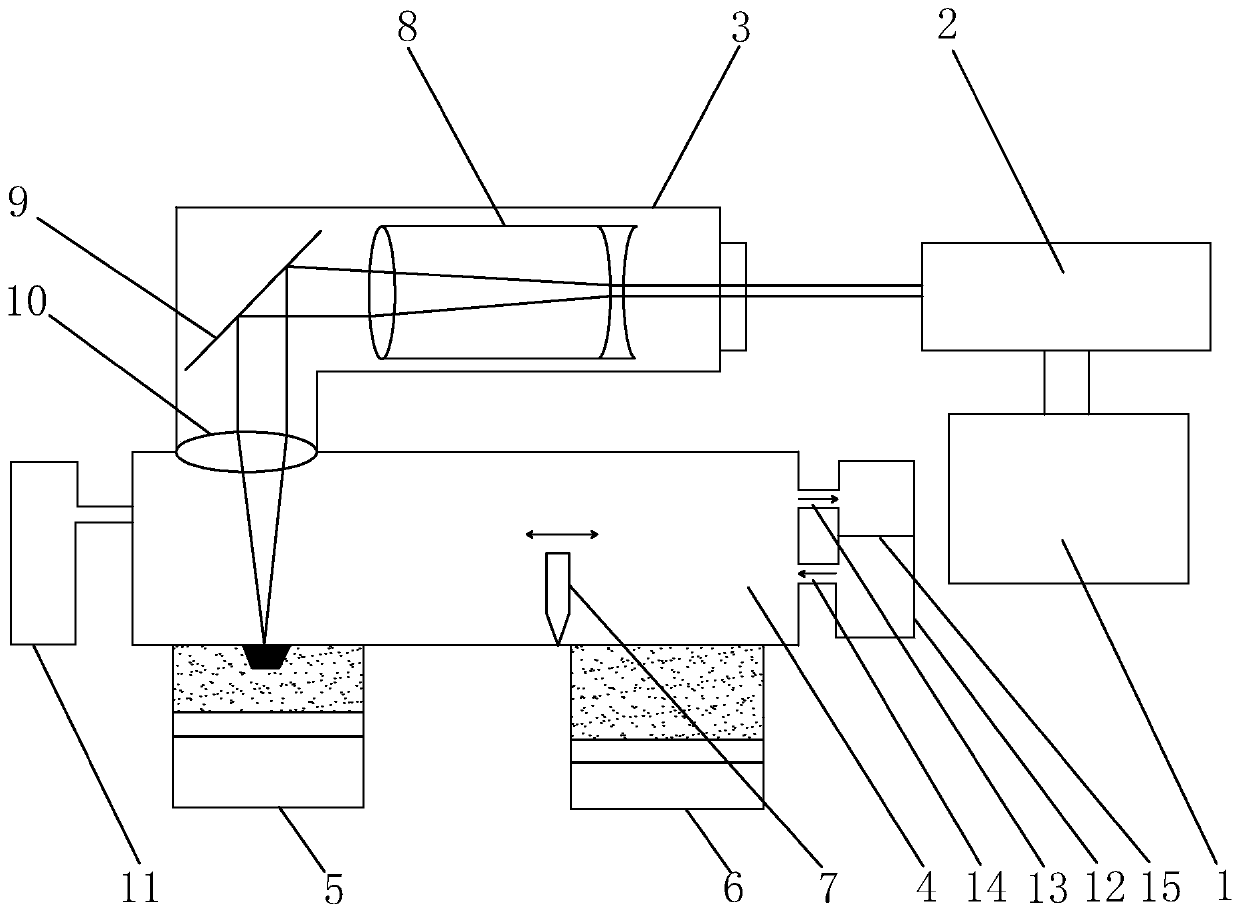

[0026] Example: figure 1 It is a 3D printing device disclosed in the present invention, which includes a computer control system 1 and a molding chamber 4. The computer control system 1 is connected to a fiber laser 2, and the top of the molding chamber 4 is connected to a beam isolator 3. One end of the beam isolator 3 faces the laser light emitted by the fiber laser 2 , and an F-Theta lens 10 is provided at the connection between the other end of the beam isolator 3 and the molding chamber 4 . The beam isolator 3 is L-shaped, and the vibrating mirror 9 and the beam expander 8 are fixed inside the beam isolator 3 , wherein the vibrating mirror 9 is located at a corner of the beam isolator 3 . The laser light passes through the beam expander 8 first, then is refracted by the vibrating mirror 9 , then passes through the F-Theta lens 10 , and finally enters the molding chamber 4 .

[0027] Such as figure 1 As shown, the bottom of the molding chamber 4 is provided with a moldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com