Electromagnetic multi-cyclone stirring and casting device

A stirring casting and electromagnetic device technology, applied in the field of casting, can solve the problems of inability to achieve internal and external temperature and composition exchange, failure to meet temperature and composition exchange requirements, radial penetration depth exchange of magnetic field, etc., to eliminate columnar crystals and Effects of coarse dendrites, reduction of macro-segregation and micro-segregation, reduction of delayed solidification and shell deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

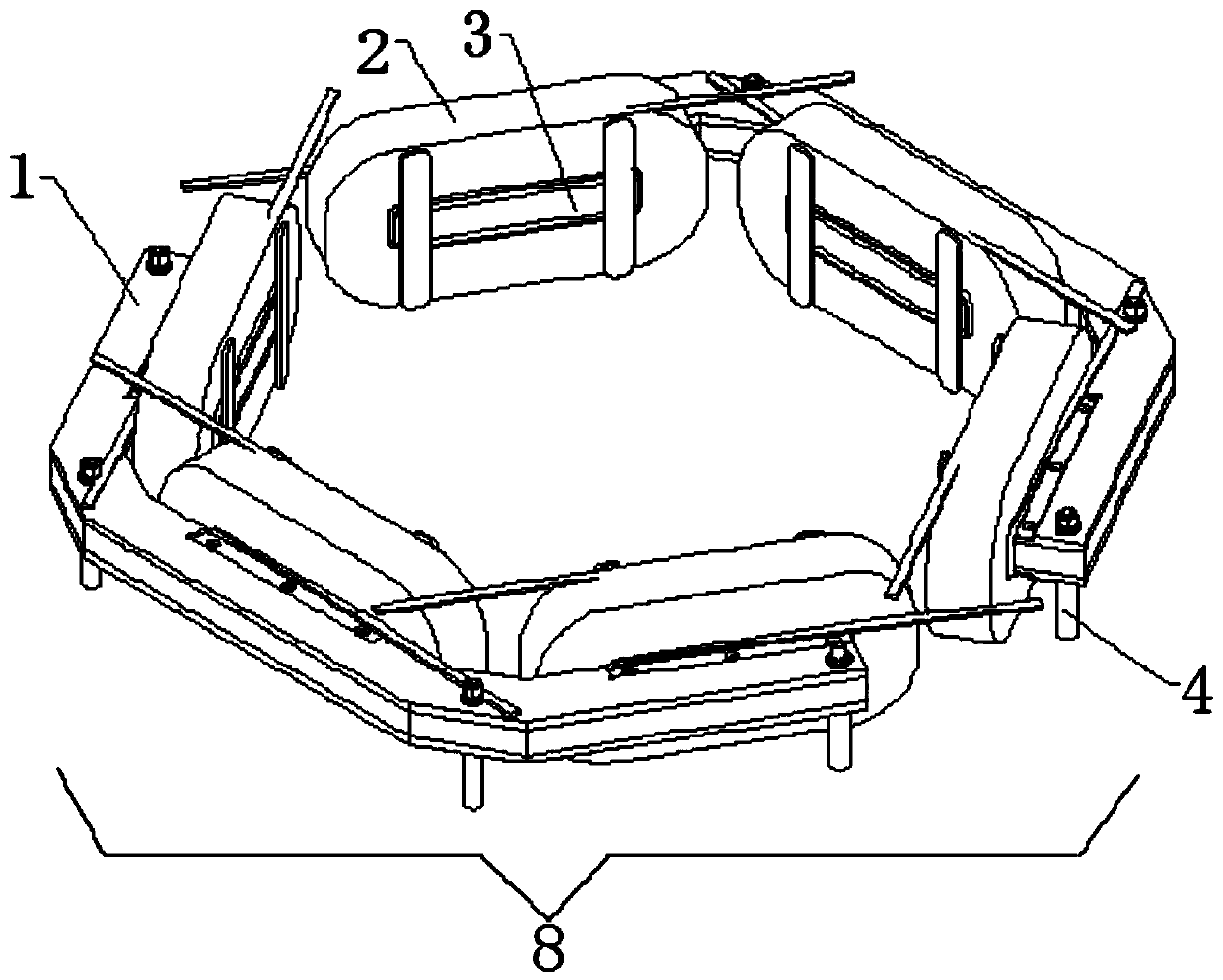

[0027] Embodiment 1: refer to figure 1 , the present invention provides a technical solution: an electromagnetic multi-swirl stirring casting device, including a water tank 7, a crystallizer 6 is installed inside the water tank 7, an electromagnetic device body 8 is installed outside the crystallizer 6, and the electromagnetic device body 8 includes a fixed rod 4. There are multiple fixed rods 4, which are divided into multiple groups. The top of each group of four fixed rods 4 is fixed with an iron core assembly 1 by screws, and the outer surface of the iron core assembly 1 is fixed with three reinforced salient poles. 3. The outer surfaces of the three reinforced salient poles 3 are wound with electromagnetic stirring coils 2, the outer surfaces of the reinforced salient poles 3 are wound with the same material and the same number of electromagnetic stirring coils 2, the electromagnetic device body 8 includes the iron core assembly 1, and the electromagnetic stirring coils C...

Embodiment 2

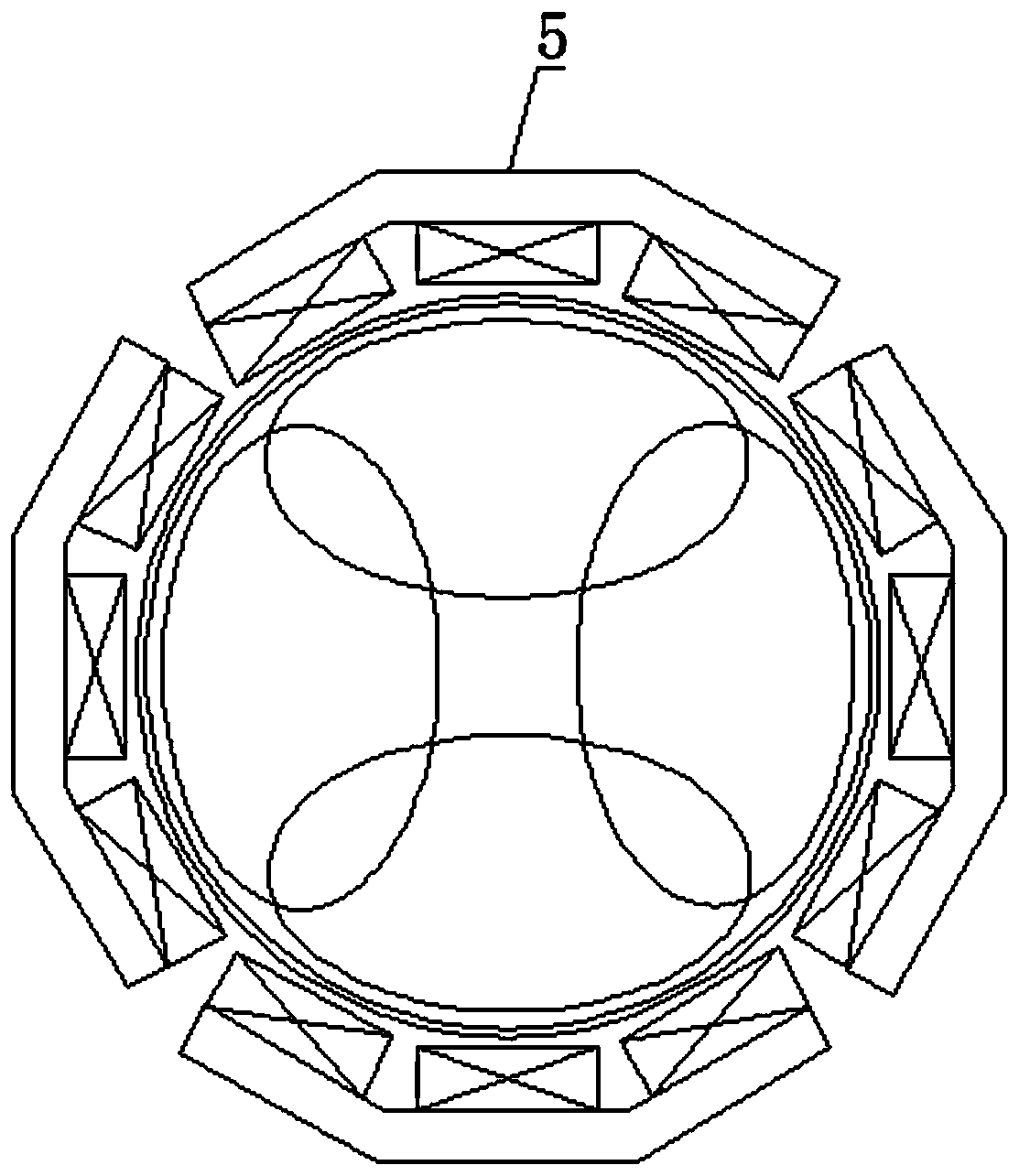

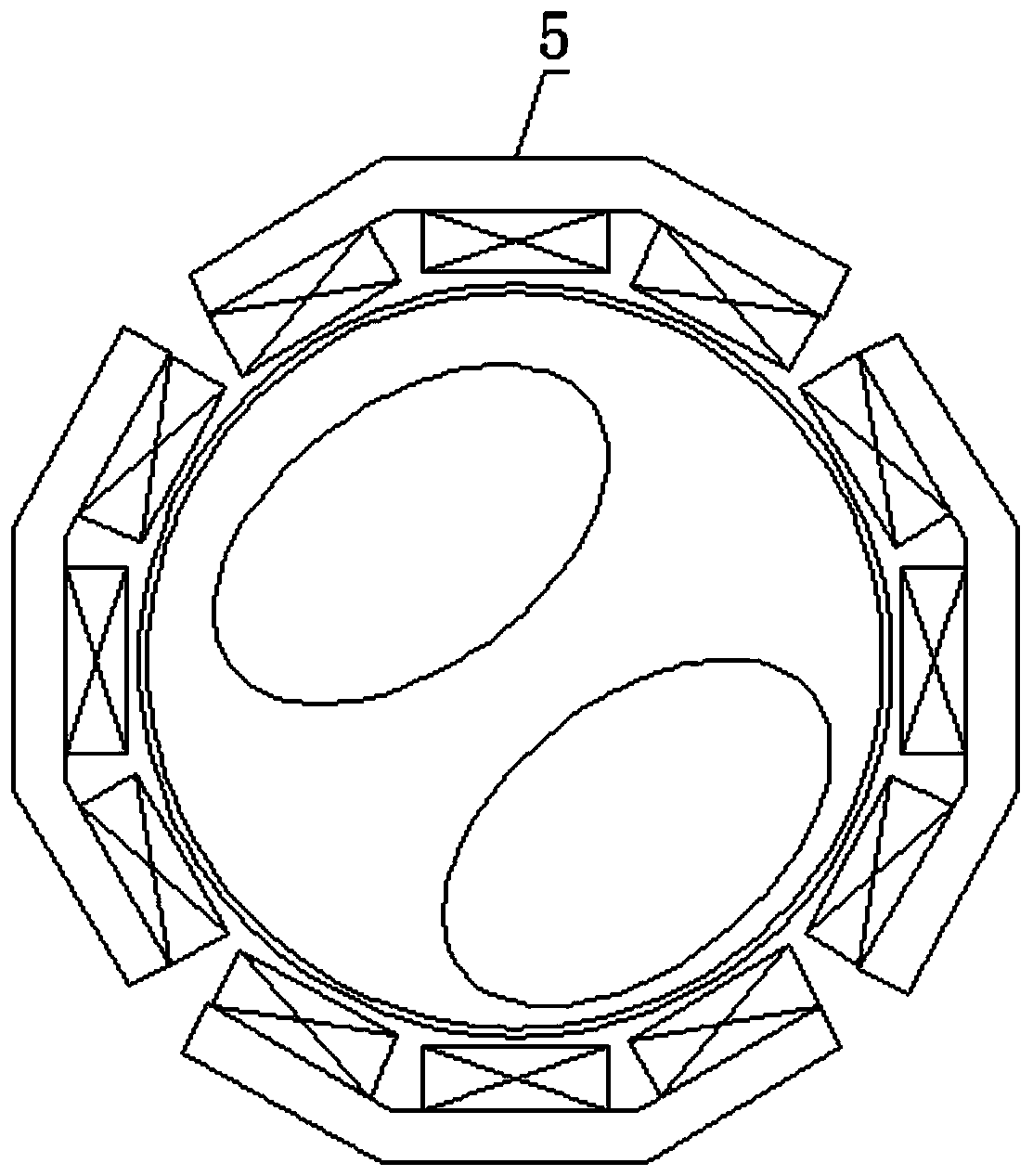

[0028] Embodiment 2: refer to Figure 2-4 , the electromagnetic stirring coil 2 is provided with a plurality, and is divided into multiple groups, and each group of three electromagnetic stirring coils 2 forms a C-type electromagnetic inductor 5, and a C-type electromagnetic inductor 5 is provided with a plurality, and each C-type The electromagnetic inductor 5 itself can form a complete swirling magnetic field. When the electromagnetic device body 8 is in use, the molten metal is subjected to the action of electromagnetic force to form a motion track. Every three coils of this device constitute a C-type electromagnetic inductor 5. Each C-type electromagnetic inductor 5 can form a complete swirl magnetic field by itself, and the C-type electromagnetic inductor 5 serves as a subunit swirl magnetic field. N C-type electromagnetic inductors form N swirl magnetic fields. Every two adjacent C-type The electromagnetic inductor 5 can synthesize a large swirling magnetic field, and al...

Embodiment 3

[0029] Embodiment 3: refer to Figure 5-6 , the electromagnetic device body 8 is installed in the lower part of the liquid cavity of the crystallizer 6, and is connected with the upper part of the water tank 7 by bolts. The electromagnetic device body 8 can also be installed below the crystallizer 6. When using the electromagnetic device body 8, the casting crystal The device 6 is installed in the water tank 7, the electromagnetic device body 8 is installed in the middle and lower part of the crystallizer 6 liquid cavity, and is connected with the upper part of the water tank 7 by bolts, and the water in the water tank 7 cools the electromagnetic stirring coil 2 while cooling the crystallizer 6 , when the crystallizer 6 is a short crystallizer 6, it can also be hung with the bottom of the crystallizer 6 according to actual conditions.

[0030] When in use, since each reinforced salient pole 3 of the stirrer is wound with the same material and the same number of electromagnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com