Shaft repair device under complex stress conditions

A technology with complex stress and conditions, applied in the direction of maintenance and safety accessories, metal processing machinery parts, other manufacturing equipment/tools, etc., can solve problems such as cumbersome operation, poor health of staff, poor repair accuracy, etc., and achieve reasonable structure Simplicity, prevention of environmental pollution, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

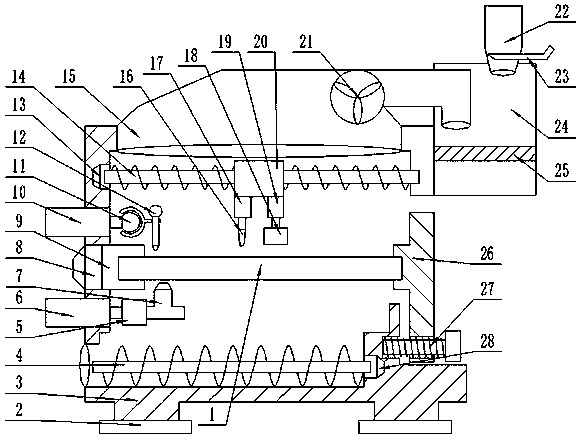

[0020] Such as figure 1 As shown, this specific embodiment adopts the following technical solutions: a shaft repair device under complex stress conditions, including a shaft 1, a base 2, a device casing 3, a screw transmission rod 4, an air pump 5, a first telescopic air rod 6, Air nozzle 7, first motor 8, fixture 9, second telescopic air rod 10, universal joint 11, lever gauge 12, second motor 13, screw mandrel 14, air suction hood 15, laser emitter 16, first cylinder 17. Dust suction grinding wheel 18, second cylinder 19, slider 20, first suction fan 21, water injection cylinder 22, valve 23, filter box 24, filter screen 25, support tailstock 26, regulating valve 27 and third motor 28 ; The bottom of the device shell 3 is fixedly connected with several bases 2; the top of the device shell 3 is provided with a suction cover 15; Net 25; the upper end of the filter box 24 is provided with a water injection cylinder 22, and a valve 23 is slidably connected to the water injectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com