Full-automatic material detection equipment

A material detection, fully automatic technology, applied in thin material handling, loading/unloading, winding strips, etc., can solve problems such as inability to perform automatic processing, material clogging or sticking, and inability to meet user needs, etc. The effect of reducing labor costs and error rates, reducing waste, and improving inspection efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to the accompanying drawings and embodiments.

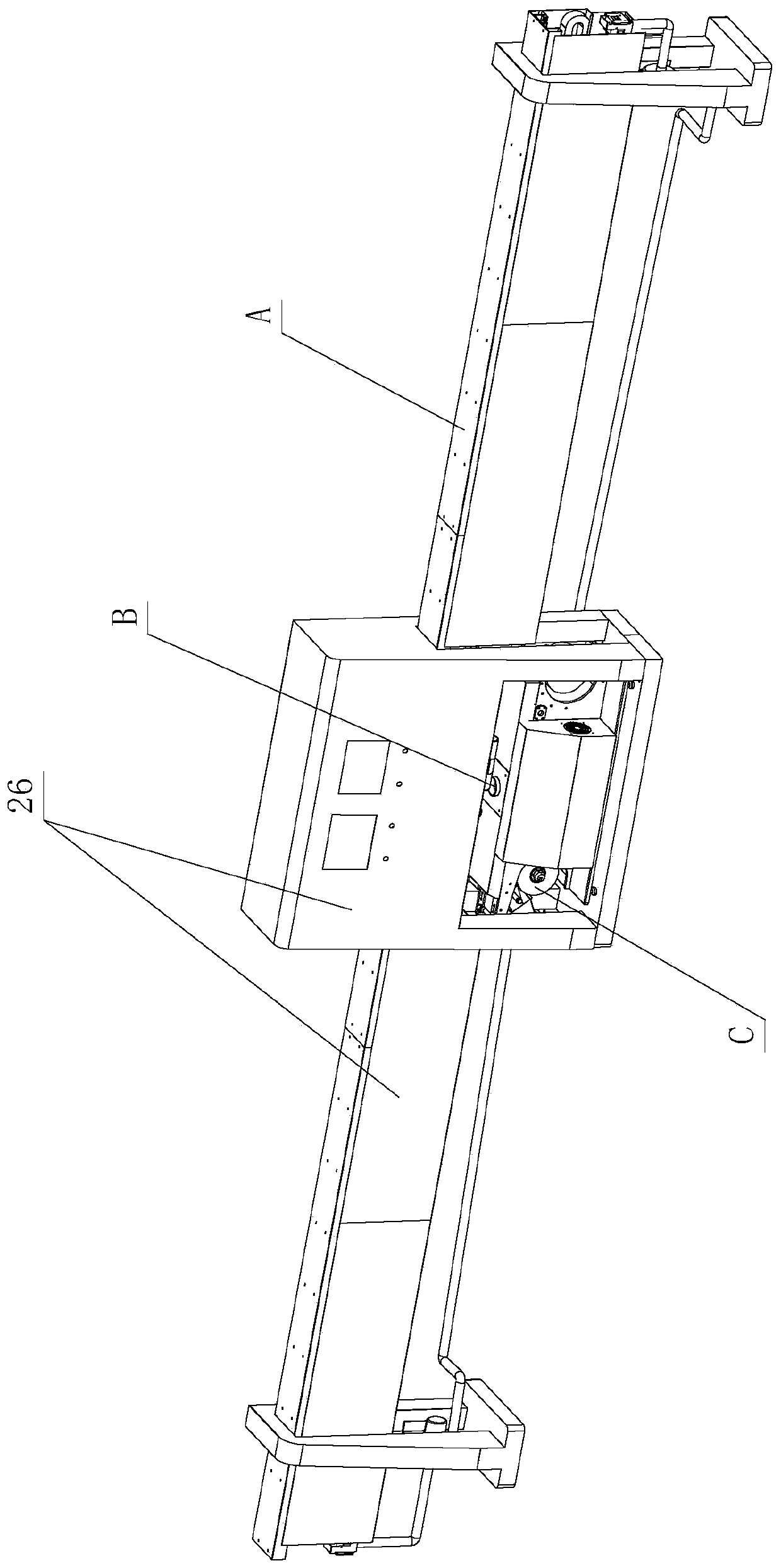

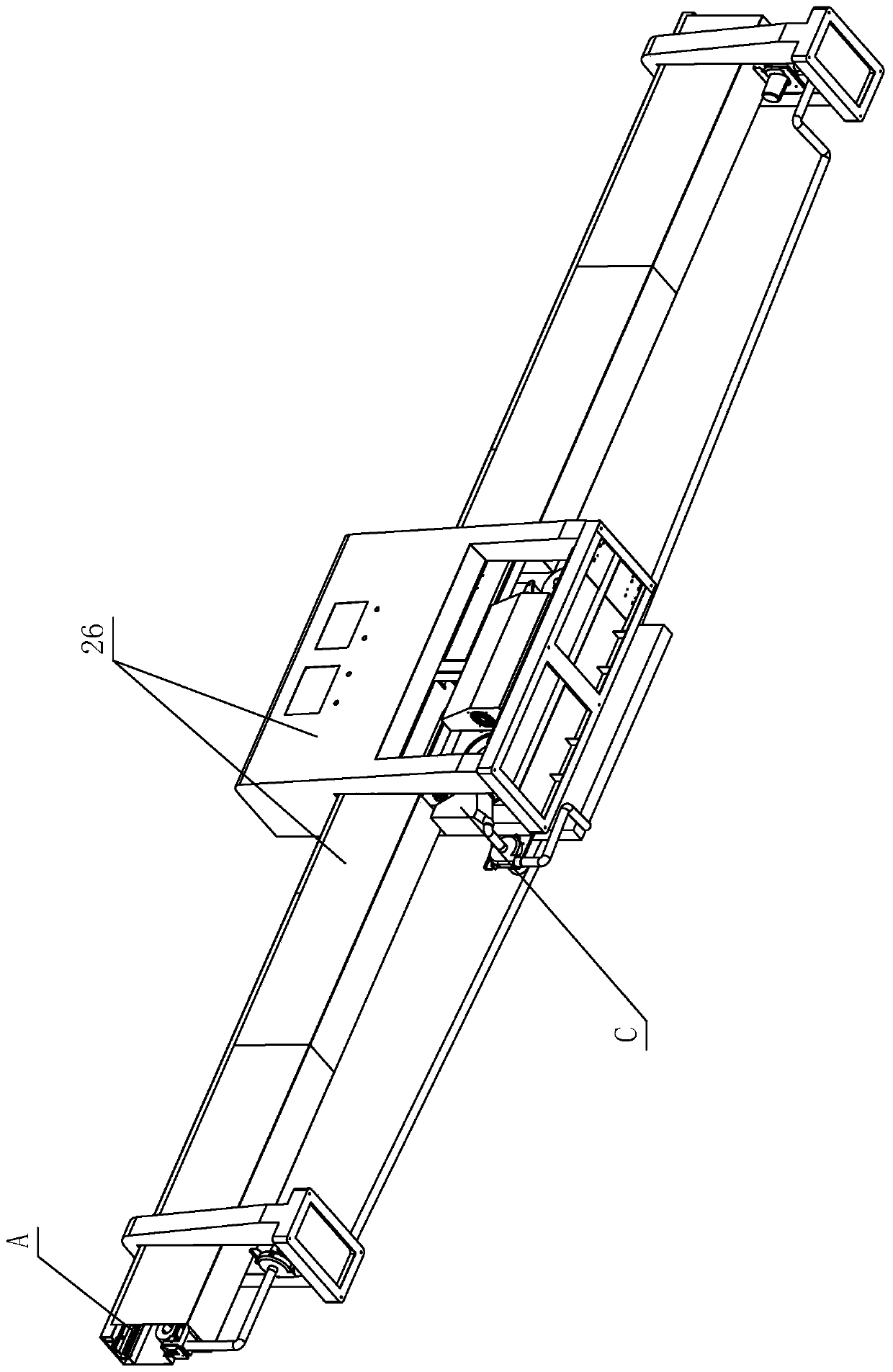

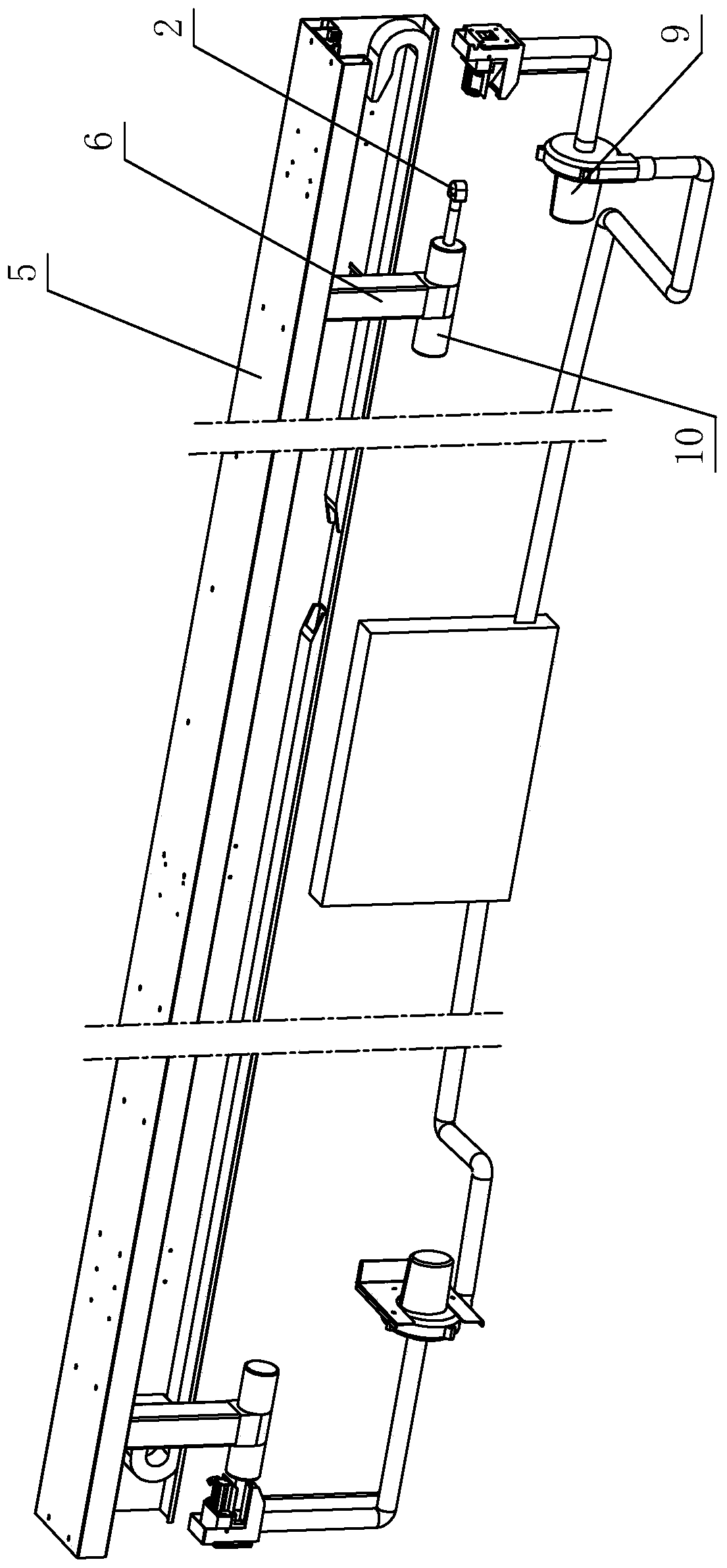

[0030] see Figure 1-Figure 8 , This fully automatic material detection equipment includes a spectrum detector 1, a reclaiming device A, a collecting device B and a film conveying device C; wherein, the reclaiming device A at least includes a reclaiming hopper 2 and a reclaiming drive assembly that are connected to each other in a driving manner, The collection device B at least includes a collection funnel 3 and a funnel driving component that are drivingly connected to each other, and the film conveying device C at least includes a material-carrying film 4 and a film driving component that are drivingly connected to each other.

[0031] The reclaiming hopper 2 is arranged above the collecting device B, and is reciprocated between the spectrum detector 1 and the reclaiming end by the driving of the reclaiming drive assembly; the collecting hopper 3 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com