Synthesis method of aluminum sulfide

A synthesis method, aluminum sulfide technology, applied in the direction of aluminum sulfide, aluminum sulfur compounds, etc., to achieve the effects of reducing costs, low reaction temperature, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

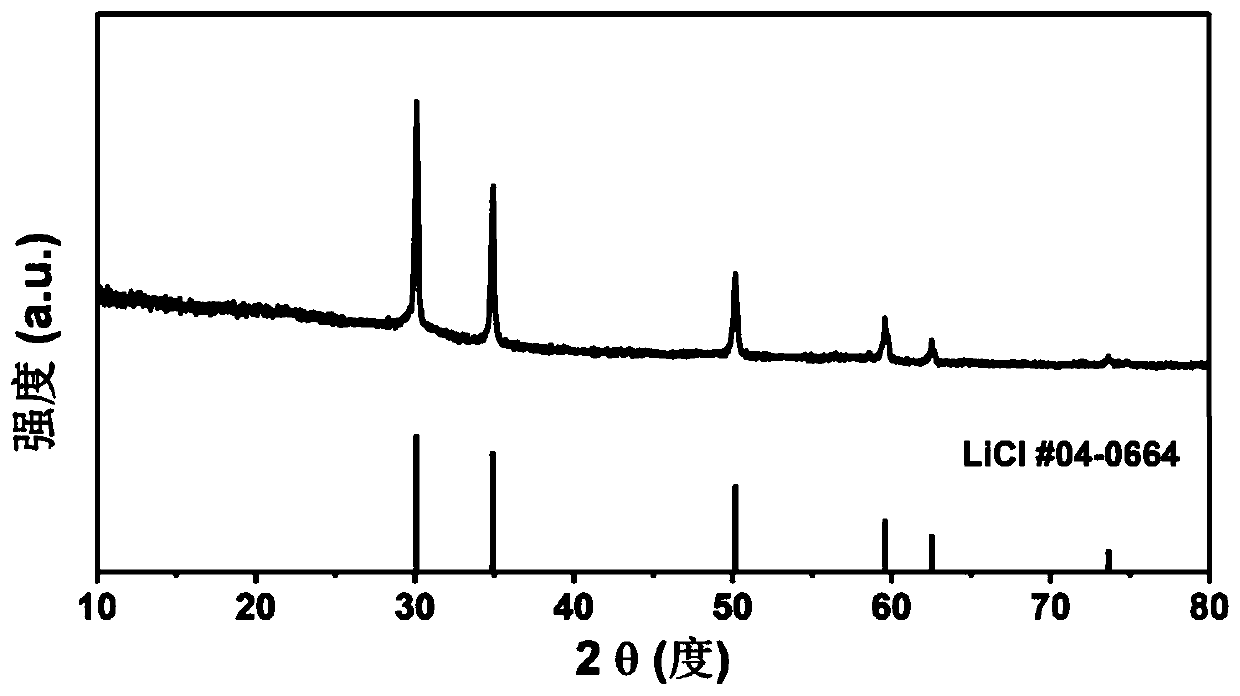

[0025] Take 0.58g of aluminum chloride and 0.3g of lithium sulfide powder, grind and disperse evenly, move them into a stainless steel reactor lined with a cylindrical corundum crucible, heat to 150°C, and keep warm for 3 hours. After the reaction is completed and cooled, pour the obtained solid powder into Put it into absolute ethanol, separate the solid and liquid after washing, and finally dry the solid at 80°C to obtain aluminum sulfide powder. figure 1 It is the XRD pattern of the reaction product of Example 1. There is only the XRD peak of LiCl in the reaction product, and no XRD peaks of other substances are observed. According to the type and number of atoms before and after the chemical reaction, there must be Al in the product. 2 S 3 produce. XRD picture as shown figure 1 shown.

Embodiment 2

[0027] Take 0.58g of aluminum chloride and 0.3g of lithium sulfide powder, grind and disperse evenly, move them into a stainless steel reactor lined with a cylindrical corundum crucible, heat to 400°C, and keep warm for 50h. After the reaction is completed and cooled, pour the obtained solid powder into Put it into absolute ethanol, separate the solid and liquid after washing, and finally dry the solid at 80°C to obtain aluminum sulfide powder.

Embodiment 3

[0029] Take 0.58g of aluminum chloride and 0.3g of lithium sulfide powder, grind and disperse evenly, move them into a stainless steel reactor lined with a cylindrical corundum crucible, heat to 300°C, and keep warm for 100h. After the reaction is completed and cooled, pour the obtained solid powder into Put it into absolute ethanol, separate the solid and liquid after washing, and finally dry the solid at 80°C to obtain aluminum sulfide powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com