Patents

Literature

35 results about "Aluminium sulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum sulfide or aluminium sulphide is a chemical compound with the formula Al₂S₃. This colorless species has an interesting structural chemistry, existing in several forms. The material is sensitive to moisture, hydrolyzing to hydrated aluminium oxides/hydroxides. This can begin when the sulfide is exposed to the atmosphere. The hydrolysis reaction generates gaseous hydrogen sulfide (H₂S).

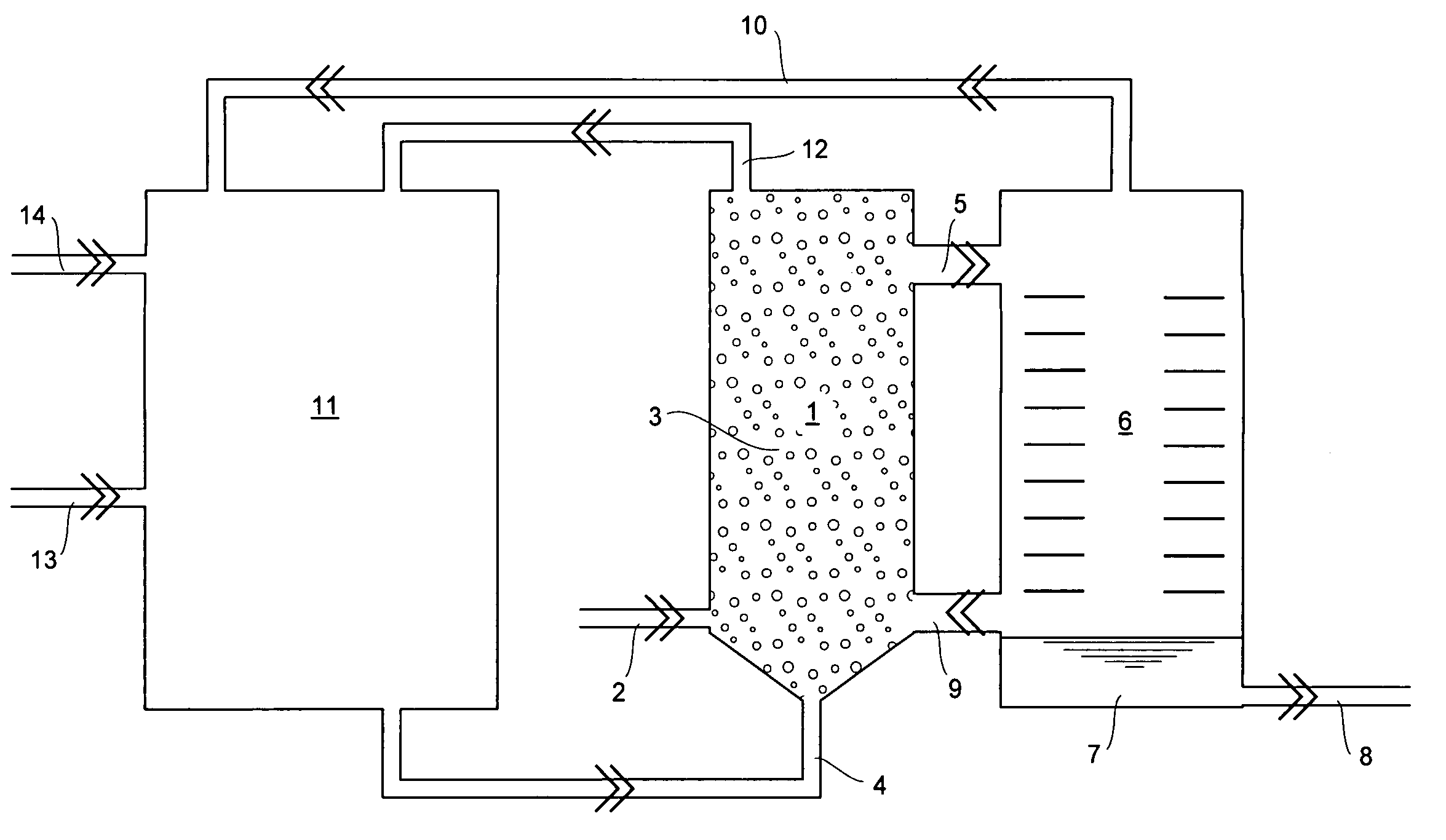

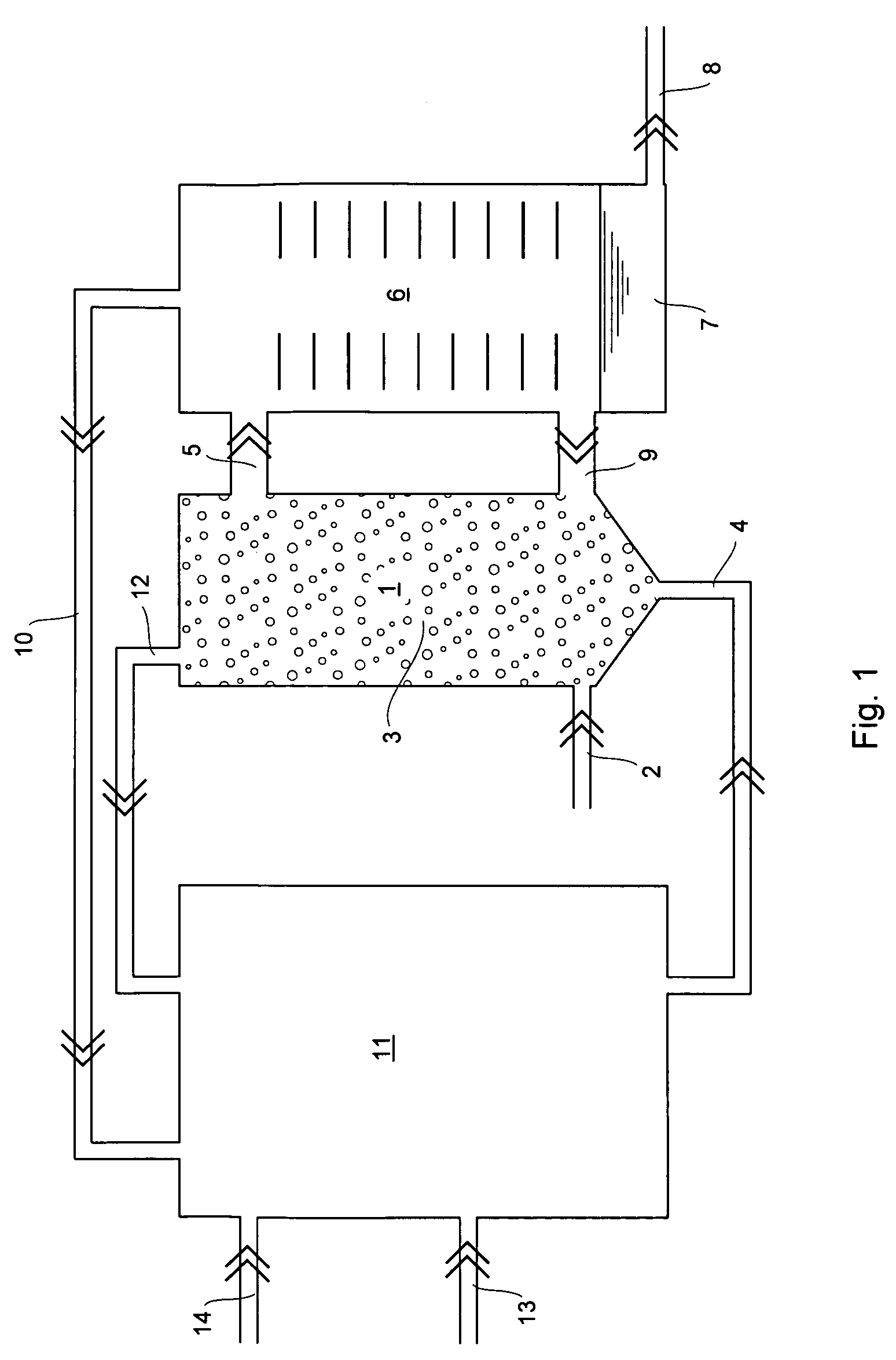

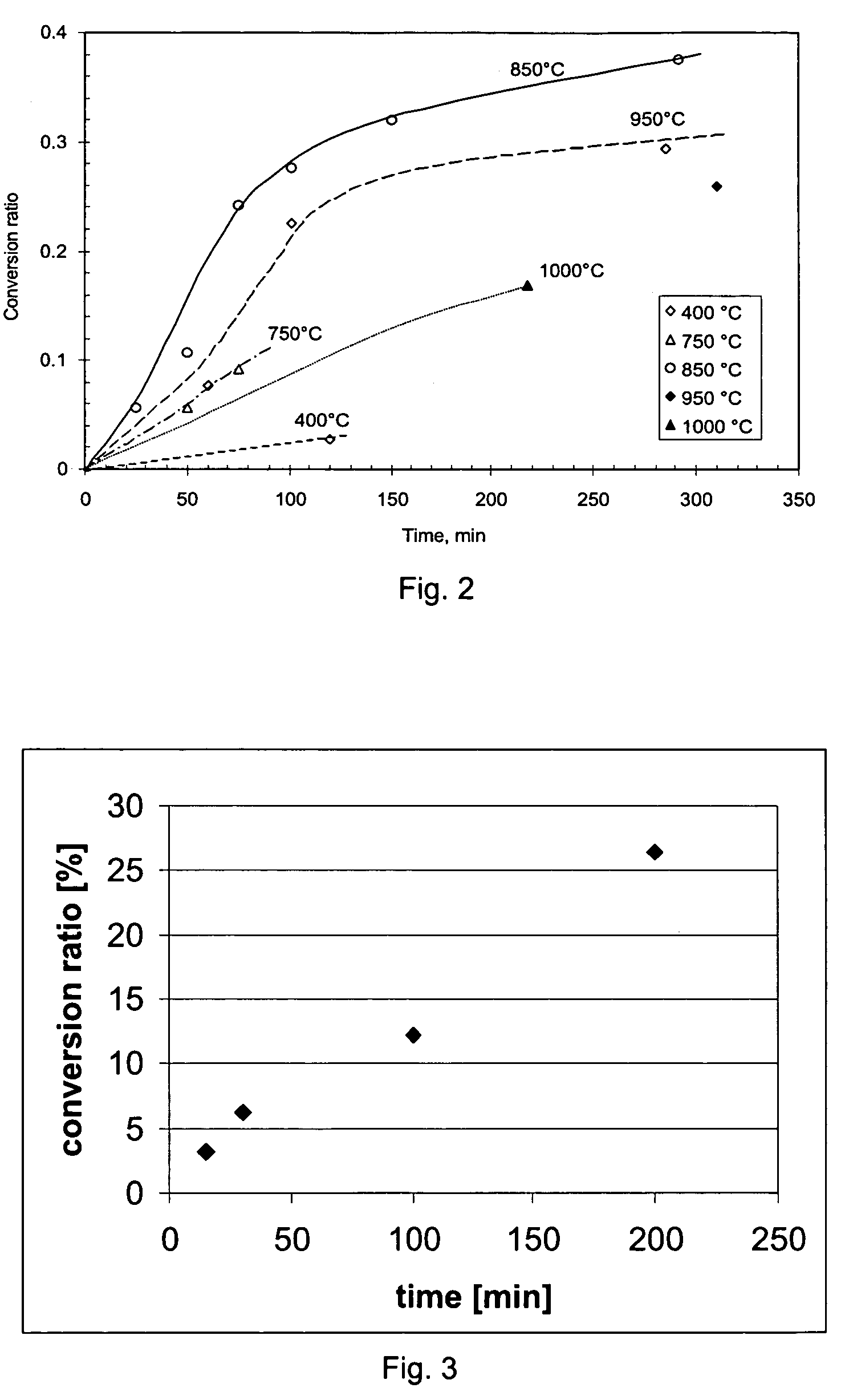

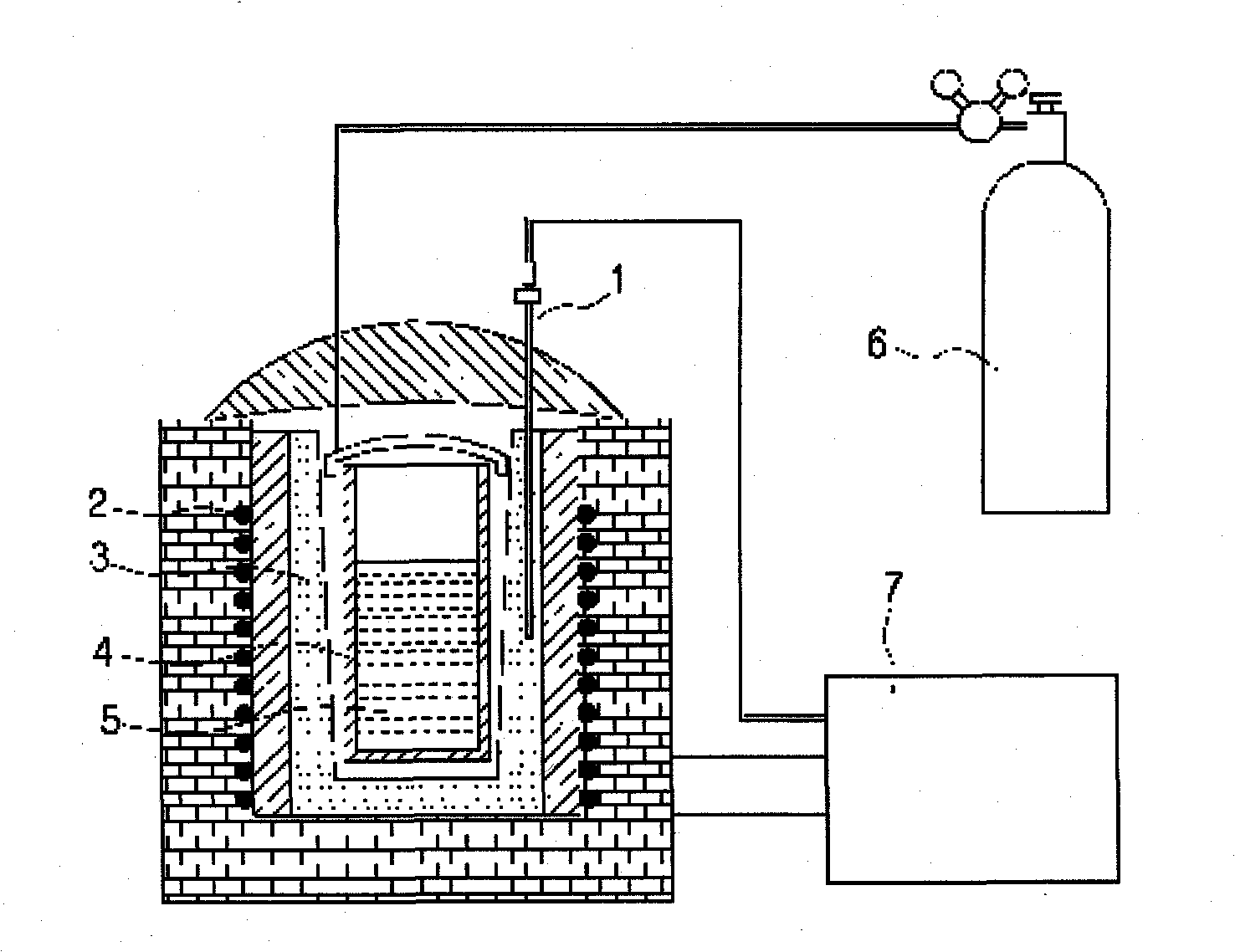

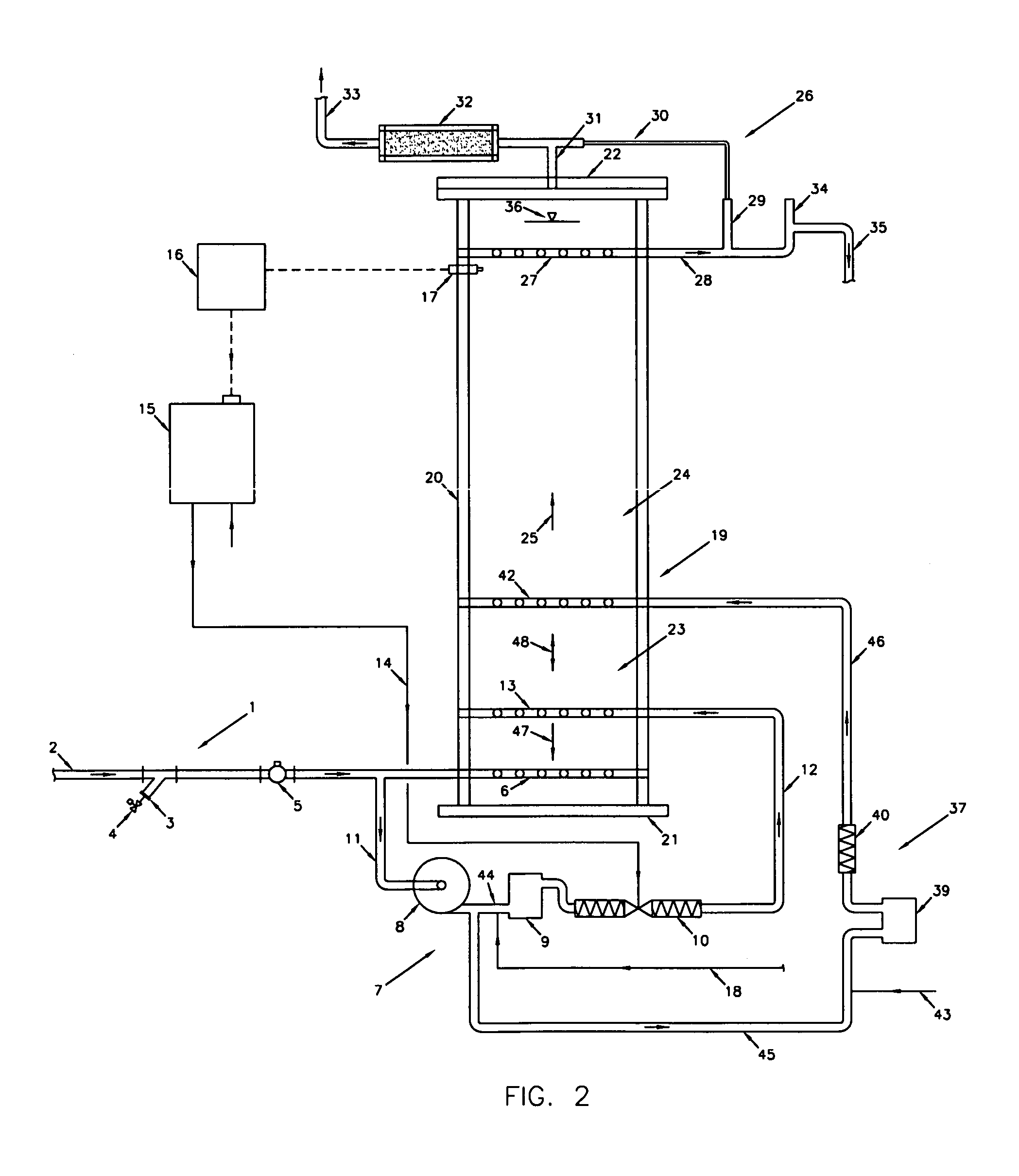

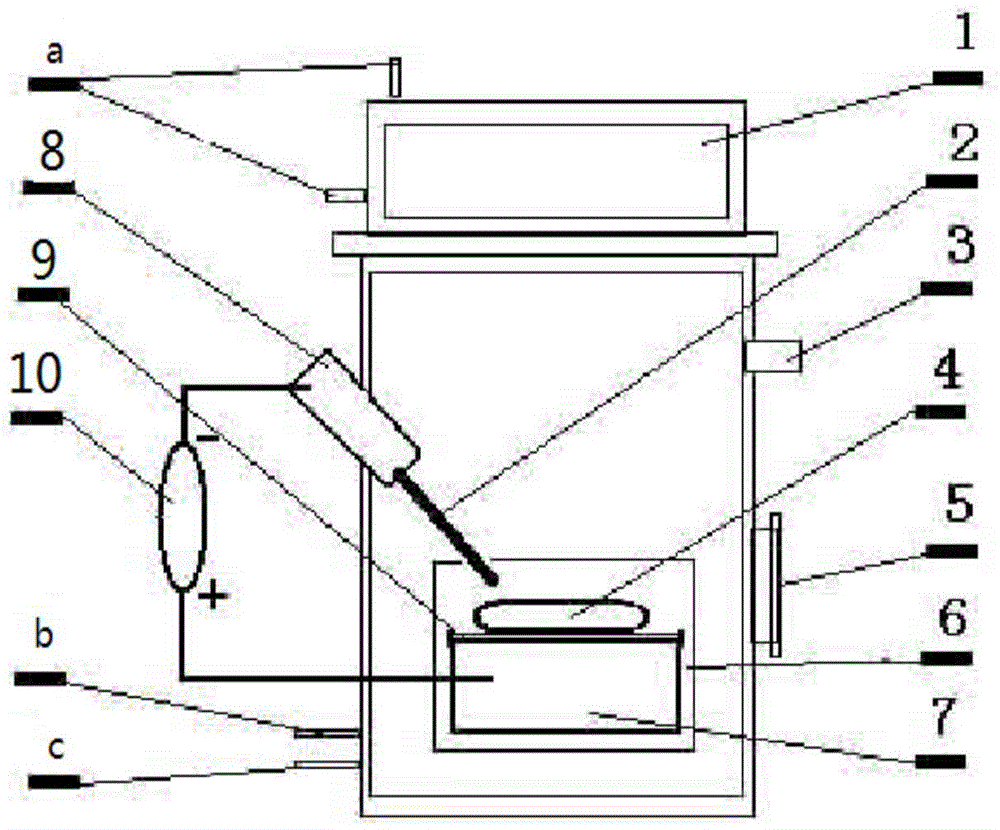

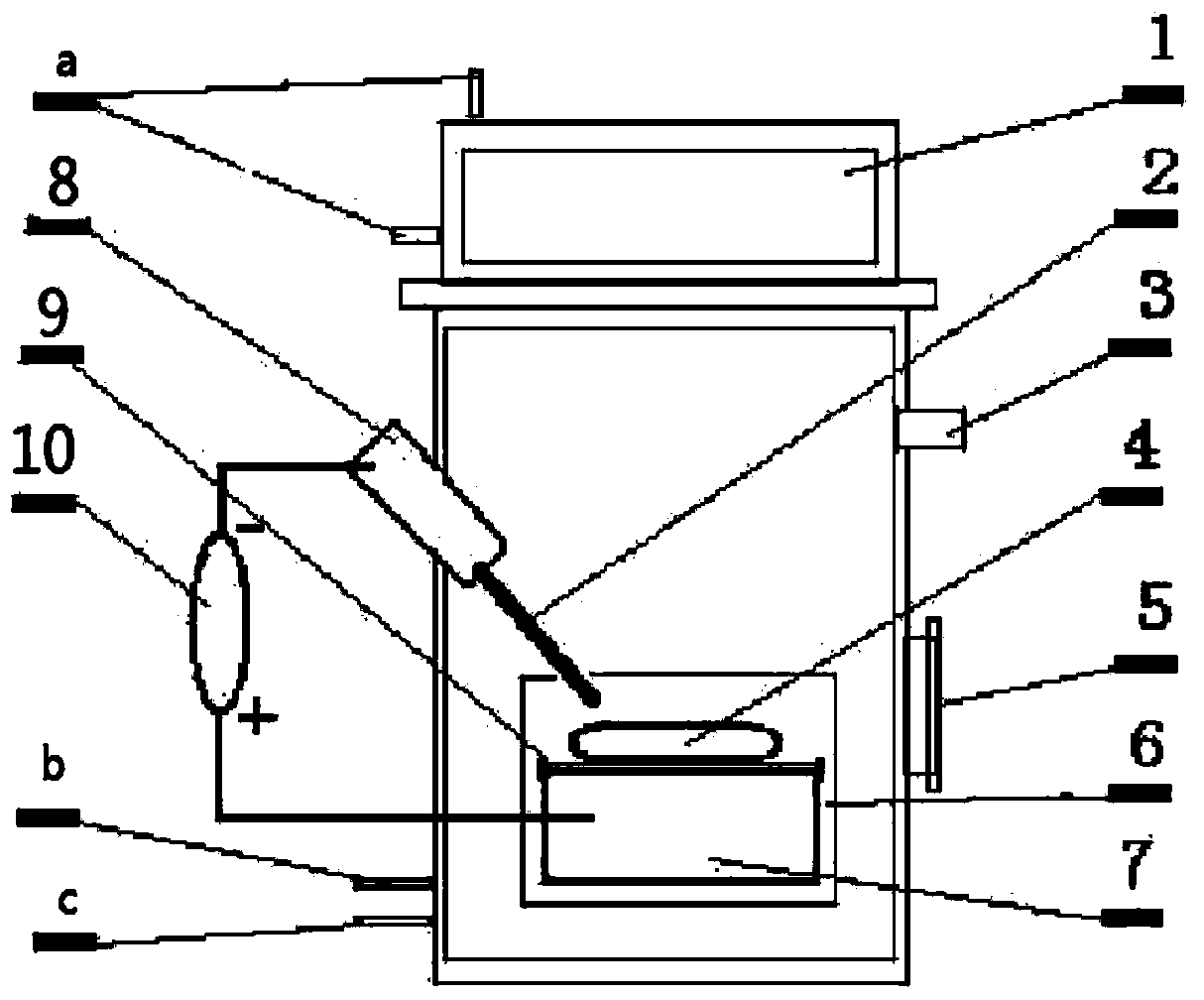

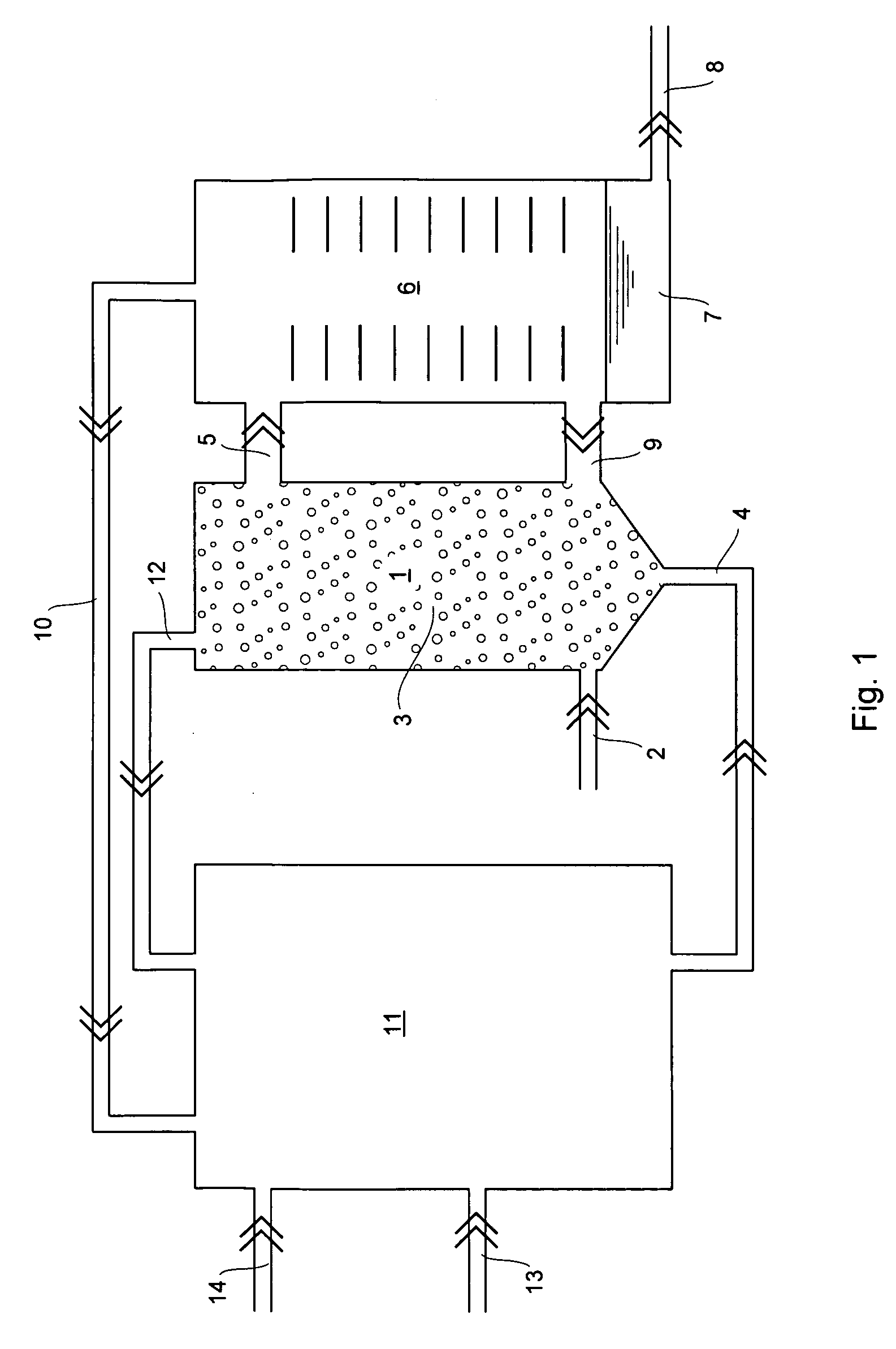

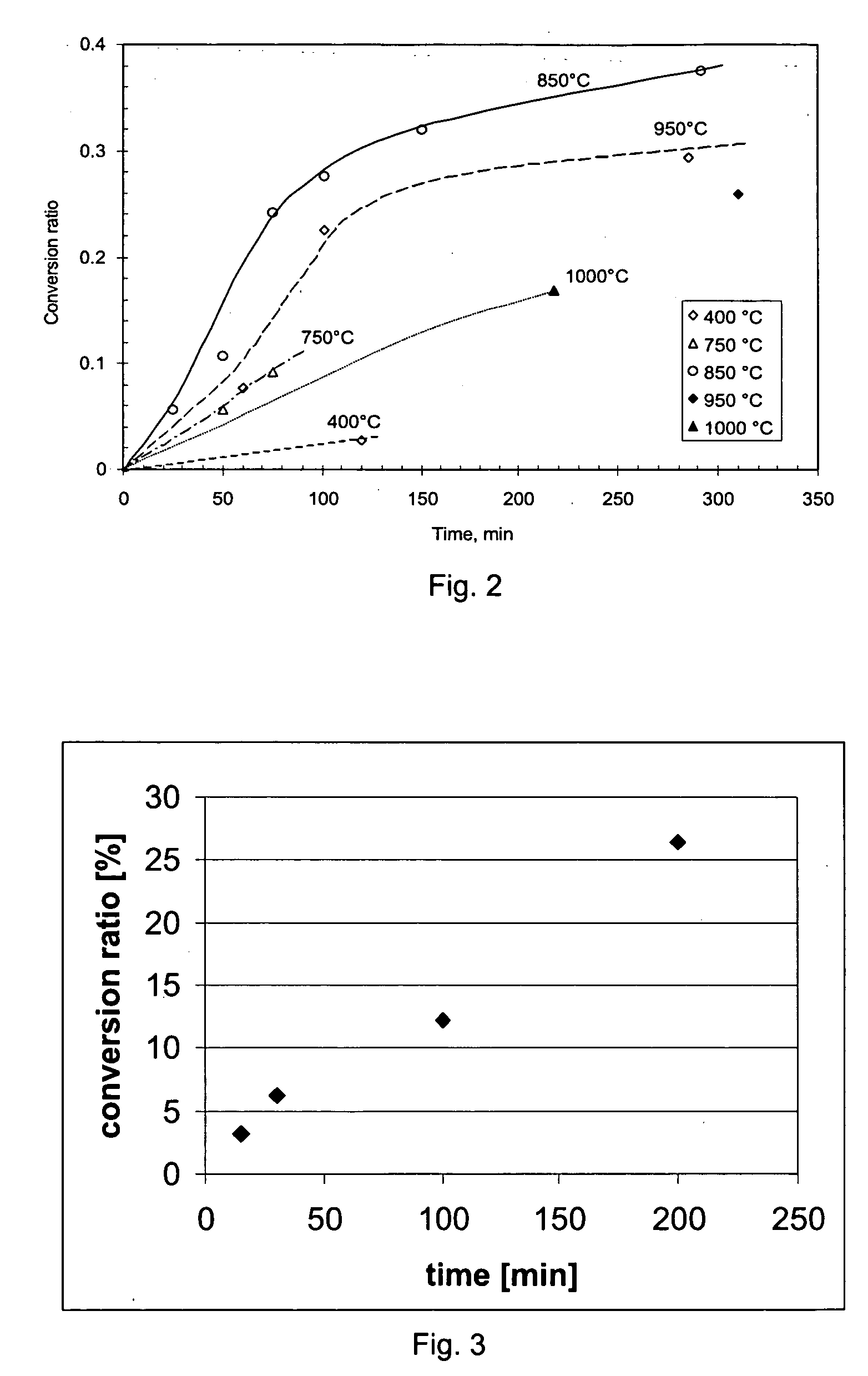

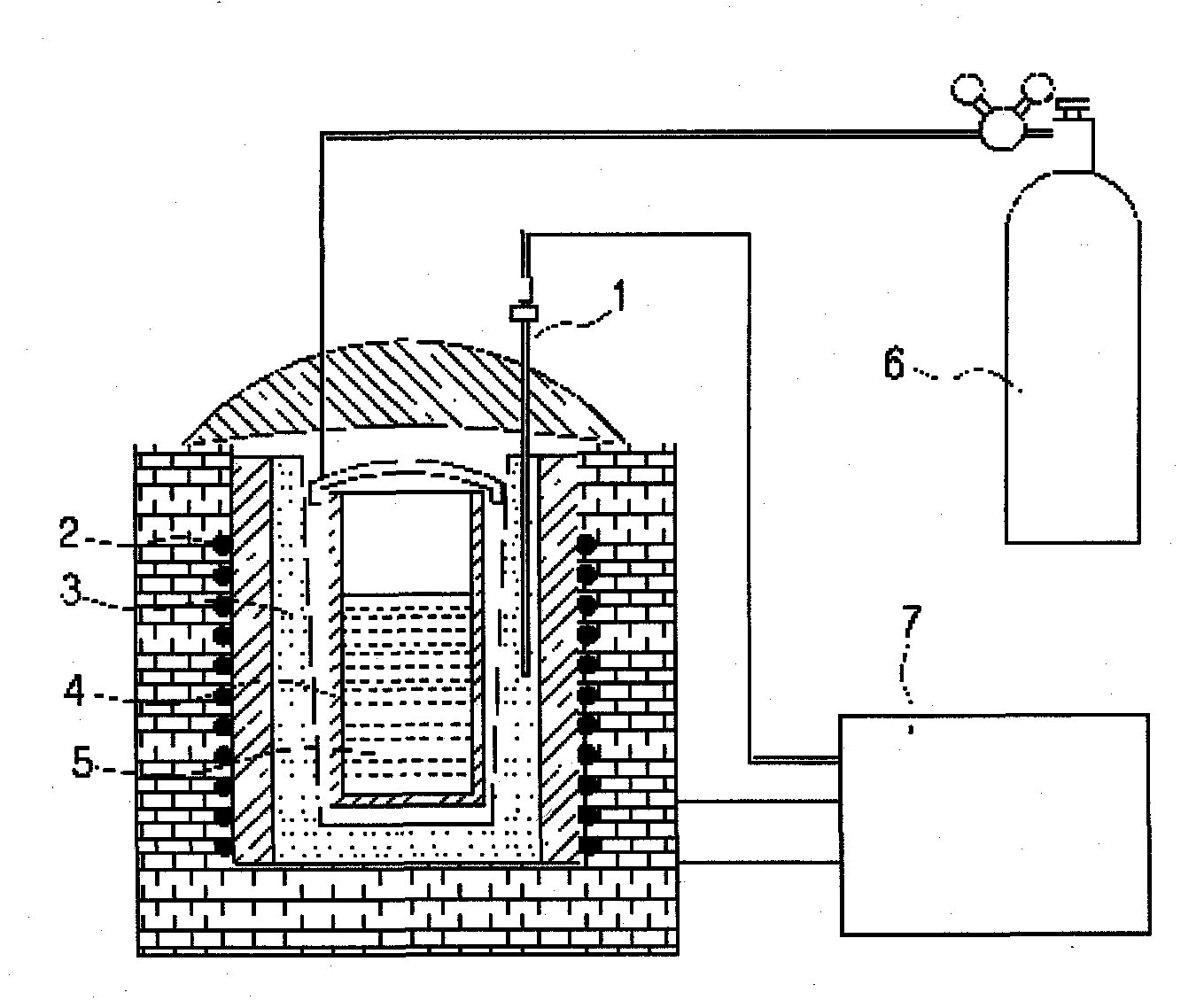

Method and apparatus for the production of aluminum

InactiveUS7867373B2Improve efficiencySpeed up the conversion processPolycrystalline material growthElectrolysis componentsMolten saltAluminium sulfide

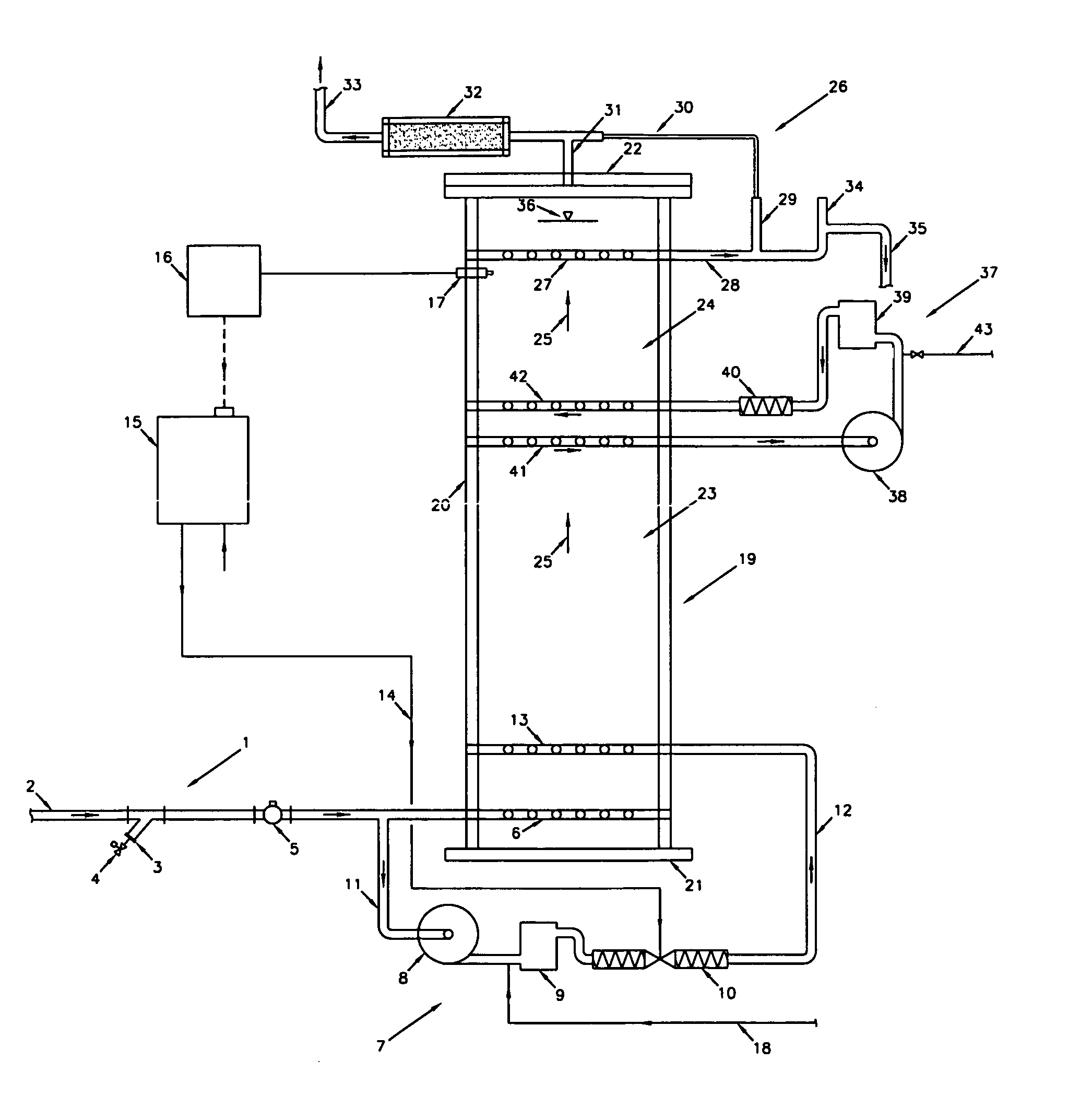

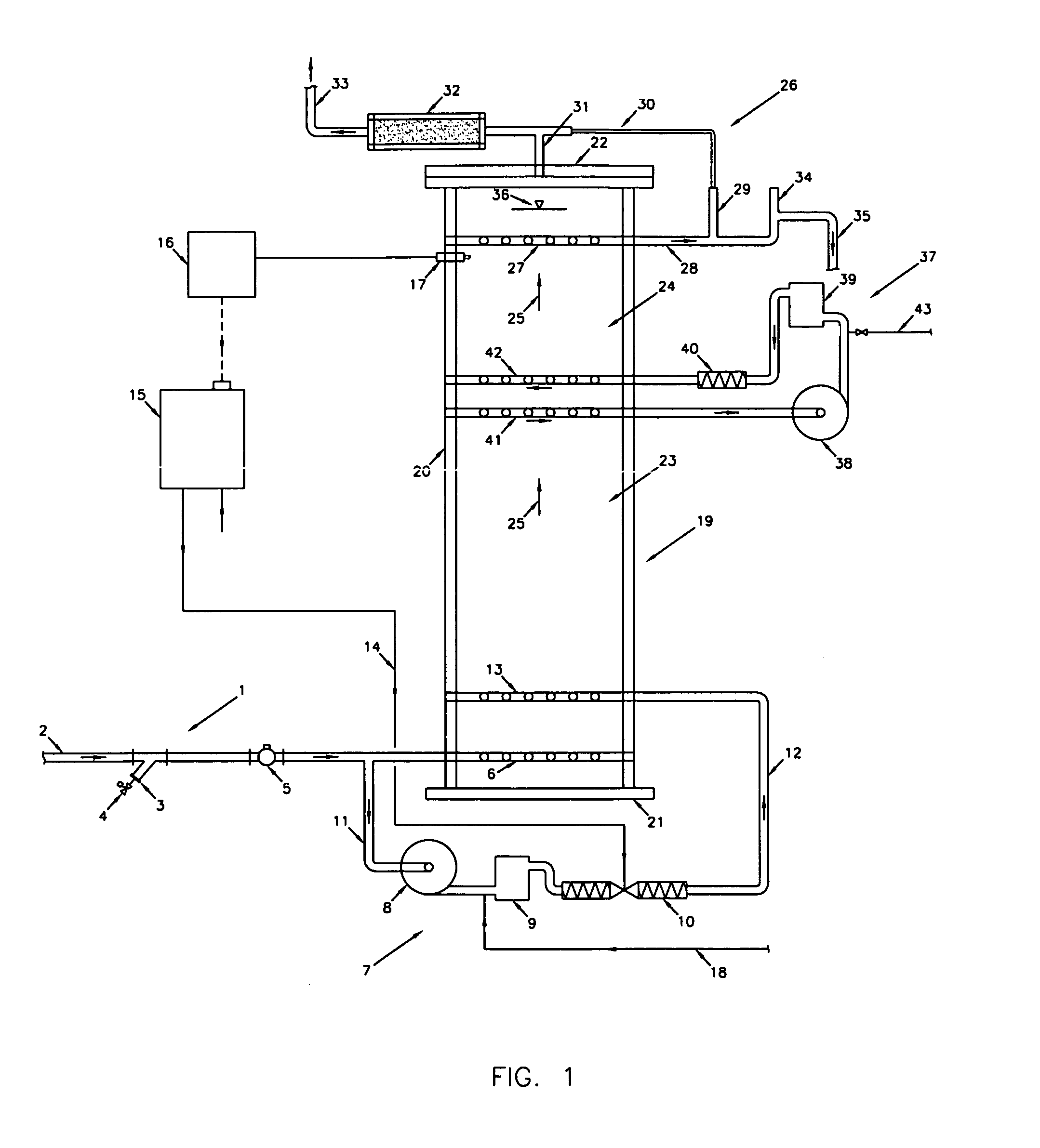

Disclosed is a method for the continuous production of aluminum from alumina including a first step of converting alumina (Al2O3) into aluminum sulfide (Al2S3) and a second step of separation of aluminum from aluminum sulfide in a separating reactor. Wherein in the first step in a conversion reactor alumina is dissolved in a molten salt to form a melt and a sulfur containing gas is fed through the melt whereby the sulfur containing gas acts as a reagent to convert at least part of the alumina into aluminum sulfide and at least part of the melt is used in the second step. Further the invention relates to an apparatus for operating the method.

Owner:ALERIS ALUMINUM KOBLENZ GMBH

Carbon fiber reinforced aluminum-based composite material and preparation method thereof

The invention discloses a carbon fiber reinforced aluminum-based composite material and a preparation method thereof. The composite material comprises the following components in percentage by mass: 1-10% of graphite powder with grain size not greater than 120 mu m, 4-9% of cobalt powder with grain size not greater than 85 mu m, 5-6% of aluminum sulfide with grain size not greater than 100 mu m, 7-9% of zinc oxide with grain size not greater than 75 mu m, 2-6% of iron oxide with grain size not greater than 40 mu m, 1-5% of sodium carboxymethyl cellulose with grain size not greater than 30 mu m, 4-20% of silicon carbide with grain size not greater than 25 mu m, and the balance of aluminum powder with grain size not greater than 60 mu m. The preparation method of the carbon fiber reinforced aluminum-based composite material comprises the following steps: uniformly mixing the components, enabling the mixed components to pass through a 200-mesh sieve specified in GB6003, and then, dry-mixing for at least 1-2 hours; carrying out compression molding under pressure of 700-800 MPa; sintering at 800-1200 DEG C, wherein the sintering pressure is 2-3MPa, the heat preserving time is 30-40 minutes; and cooling. The silicon carbide is added to greatly refine a matrix structure, so that the particle size distribution is uniform, the tensile strength and the yield strength are strengthened, and the hardness is high.

Owner:广州贵宇光电材料科技有限公司 +1

Environment-friendly dyeing agent for textile fabric

An environment-friendly dyeing agent for textile fabric is prepared from raw materials in parts by weight as follows: 5-7 parts of aluminum sulfide, 3-6 parts of polypropylene glycol, 8-16 parts of starch, 3-4 parts of zinc stearate, 4-7 parts of propyl acetate, 5-6 parts of polyvinylpyrrolidone, 7-10 parts of ethyltriethoxysilane, 6-12 parts of sodium hydroxide, 4-7 parts of sodium carbonate, 3-5 parts of ethanol, 6-8 parts of polyvinylpyrrolidone, 20-26 parts of water and 8-17 parts of polyvinyl alcohol. The environment-friendly dyeing agent for the textile fabric has the benefits as follows: with the adoption of the environment-friendly dyeing agent, the color is stable after the fabric is dyed, the fabric is not prone to fading, and the dyeing agent is environment-friendly and cannot cause any damage to a human body and the environment.

Owner:青岛百千川海洋生态科技有限公司

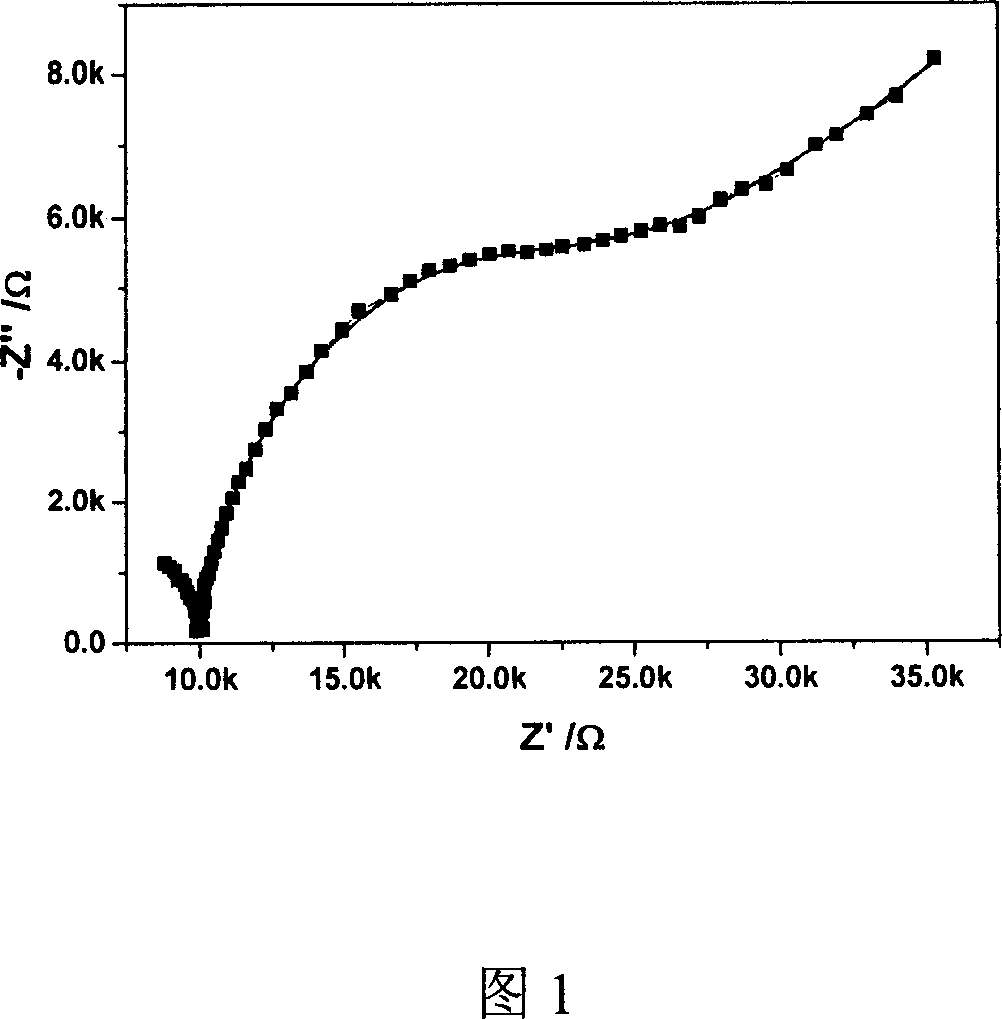

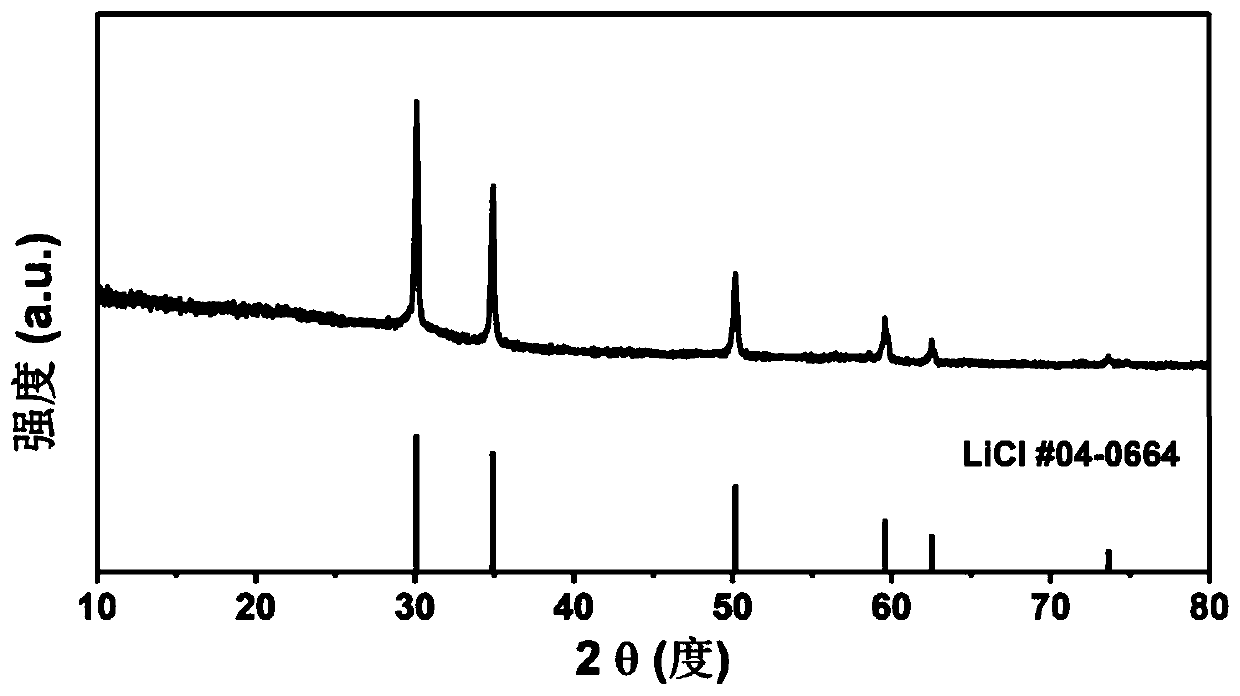

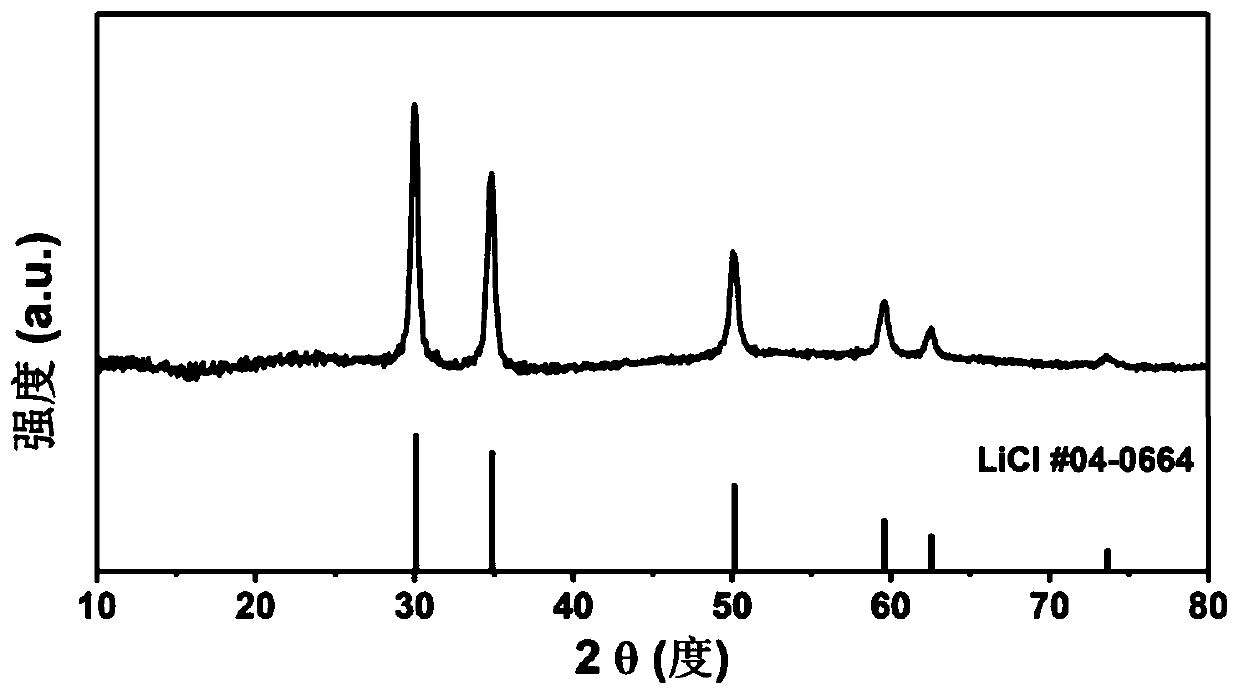

Li2S-Al2S3 solid electrolyte material for secondary lithium cell and its preparing method

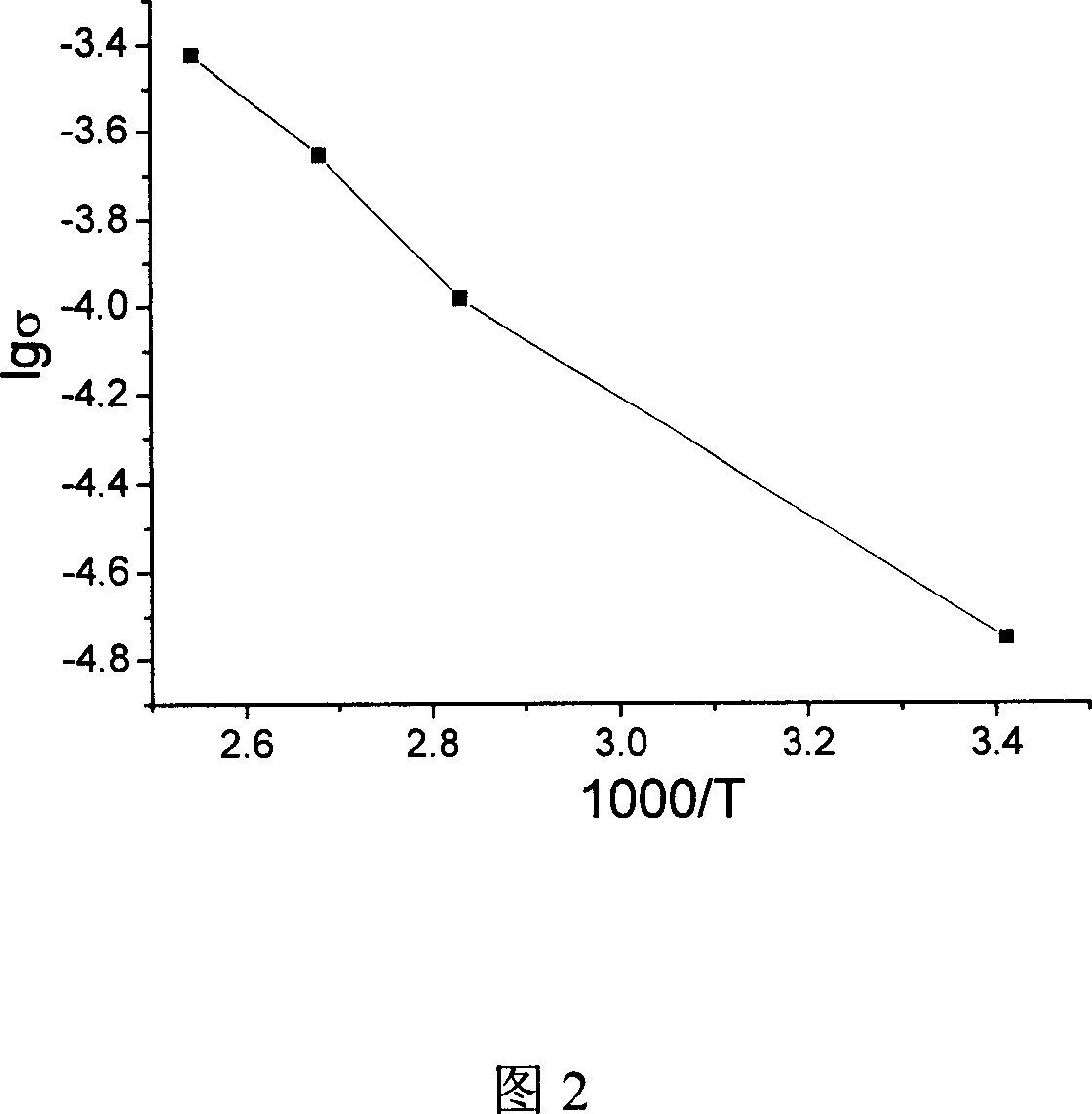

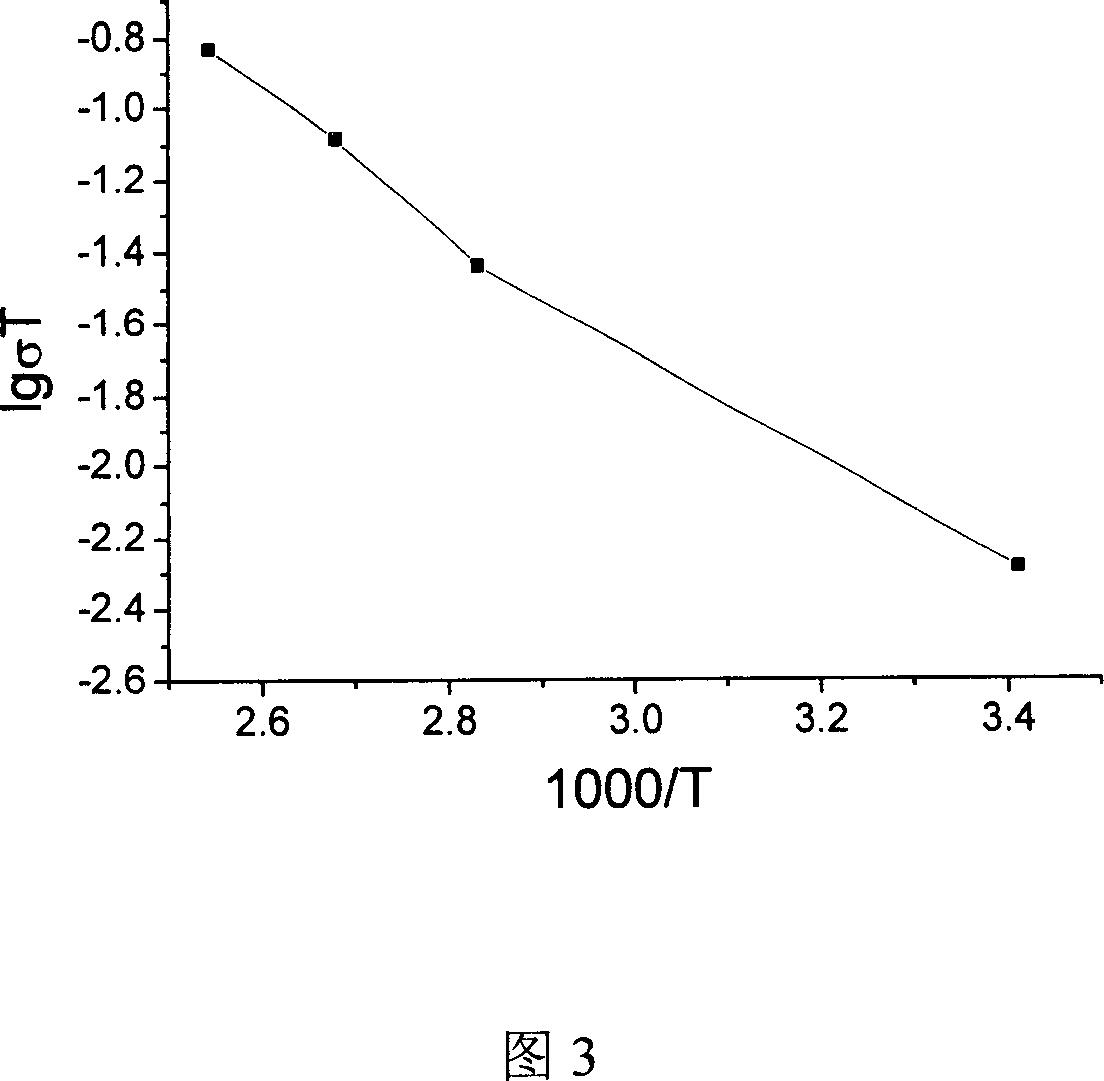

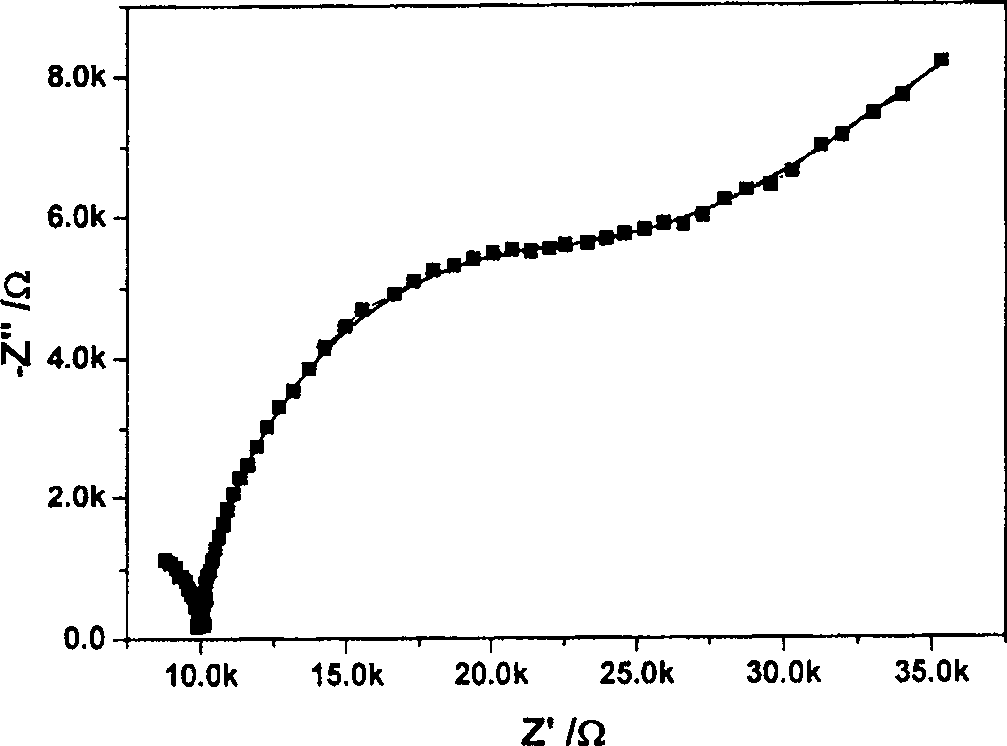

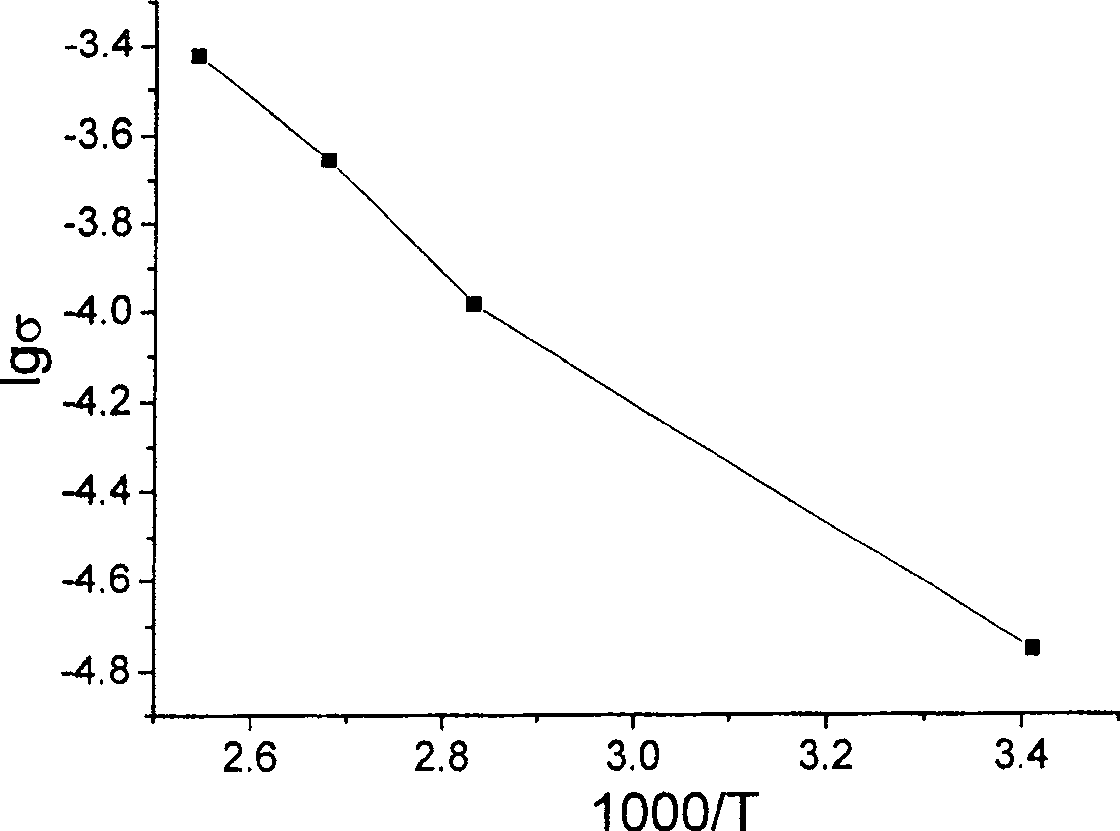

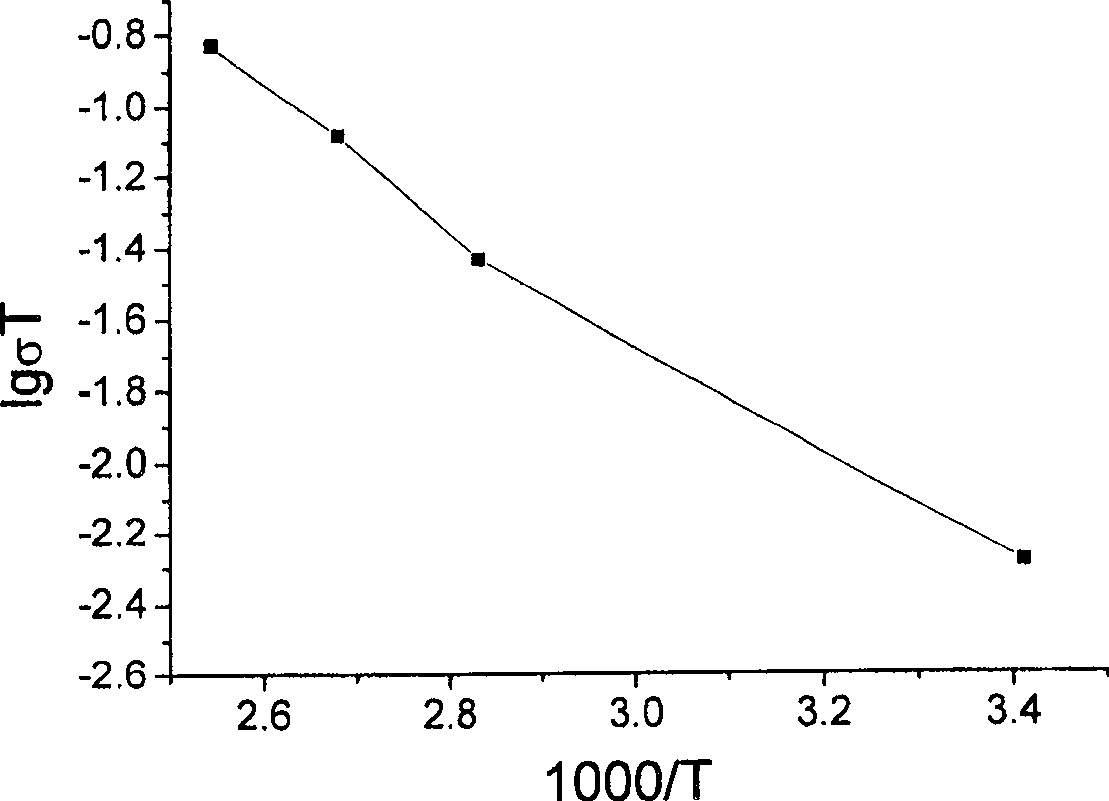

ActiveCN1937300ARich structure typeImprove ionic conductivityFinal product manufactureSecondary cells manufactureIonic conductanceActivation energy

Characters of the invention are that materials of solid electrolyte Li : Al : S=1 :1 :2 (at mol ratio) are amorphous material. Aluminum sulphide is as framework of providing transmission space for lithium ion so as to obtain higher ionic conductivity (ionic conductivity in room temperature about 1.77*10-5S / cm), lower electron conductivity (electron conductivity in room temperature less than 1.0*10-8S / cm), lower activation energy of material, and wider thermostable range. The invention provides comparative ideal candidate of electrolyte material for practical lithium ion battery in full solid state.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

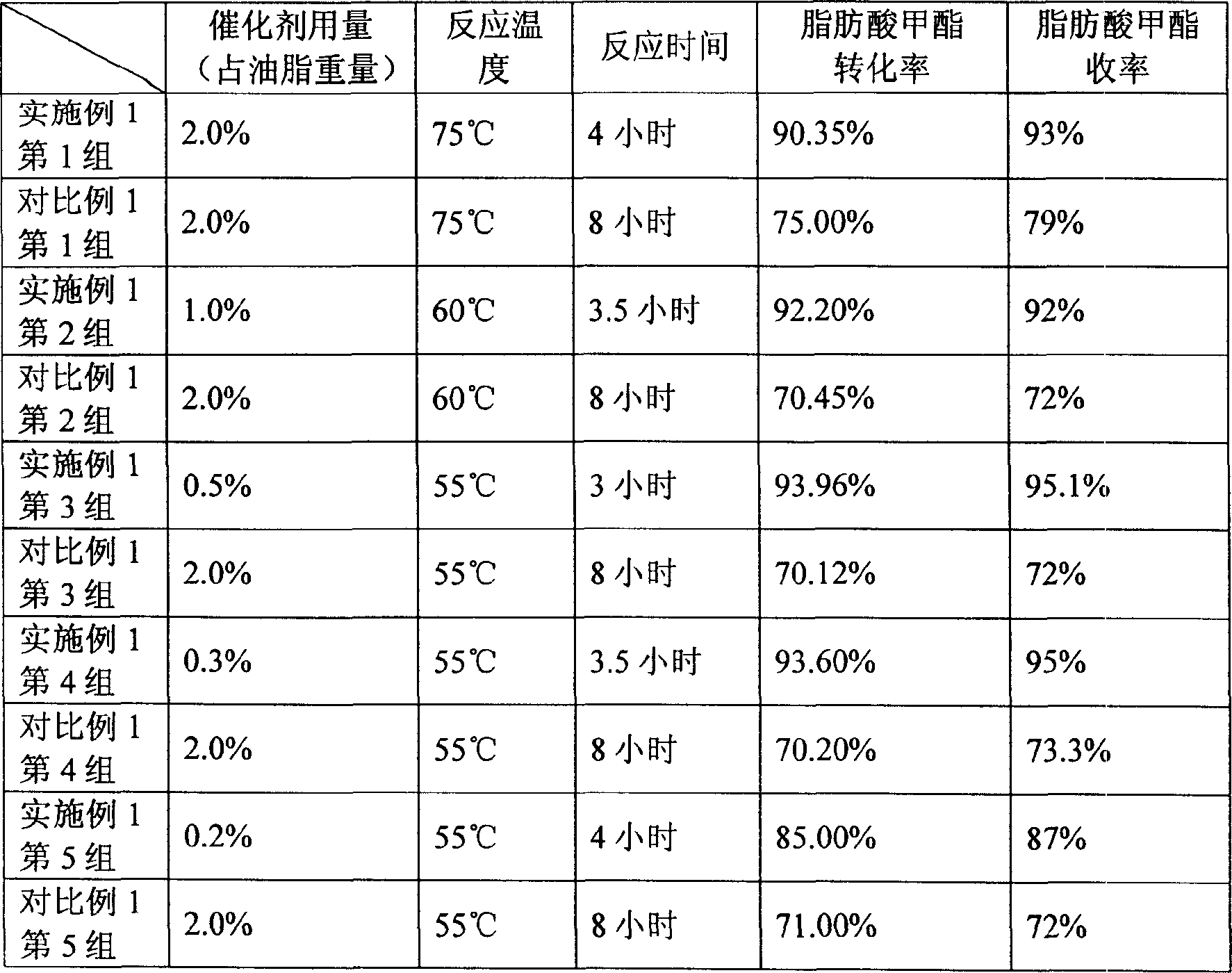

Esterification catalyst for preparing biological diesel oil by animal plant lipid and application method

InactiveCN1793288AHigh yieldReduce manufacturing costBiofuelsLiquid hydrocarbon mixture productionOil and greaseReaction temperature

The invention relates to esterifying reaction catalyst used animal and vegetable grease to manufacture biological diesel oil. It belongs to using anima and vegetable grease to manufacture biological diesel oil technique field. The catalyst includes A, B, and C three components; the A can be one or many of cadmium sulfate, zinc sulphate, or aluminium sulphate; the B is sulfuric acid quadric-ammino combine copper; the C is chromic oxide and aluminium sulfide. The invention also offers the manufacturing method. The esterifying reaction catalyst can effectively control the reaction direction to make the reversible reaction toward producing fatty acid methyl ester to make fatty glyceride esterifying ratio reach above 90%. Compared with the catalyst and application method, the invention can reduce catalyst reaction temperature, shorten catalyst reaction time, reduce end product processing program, and effectively increase biological diesel oil production quality, and reduce the fabrication cost.

Owner:赵金玉

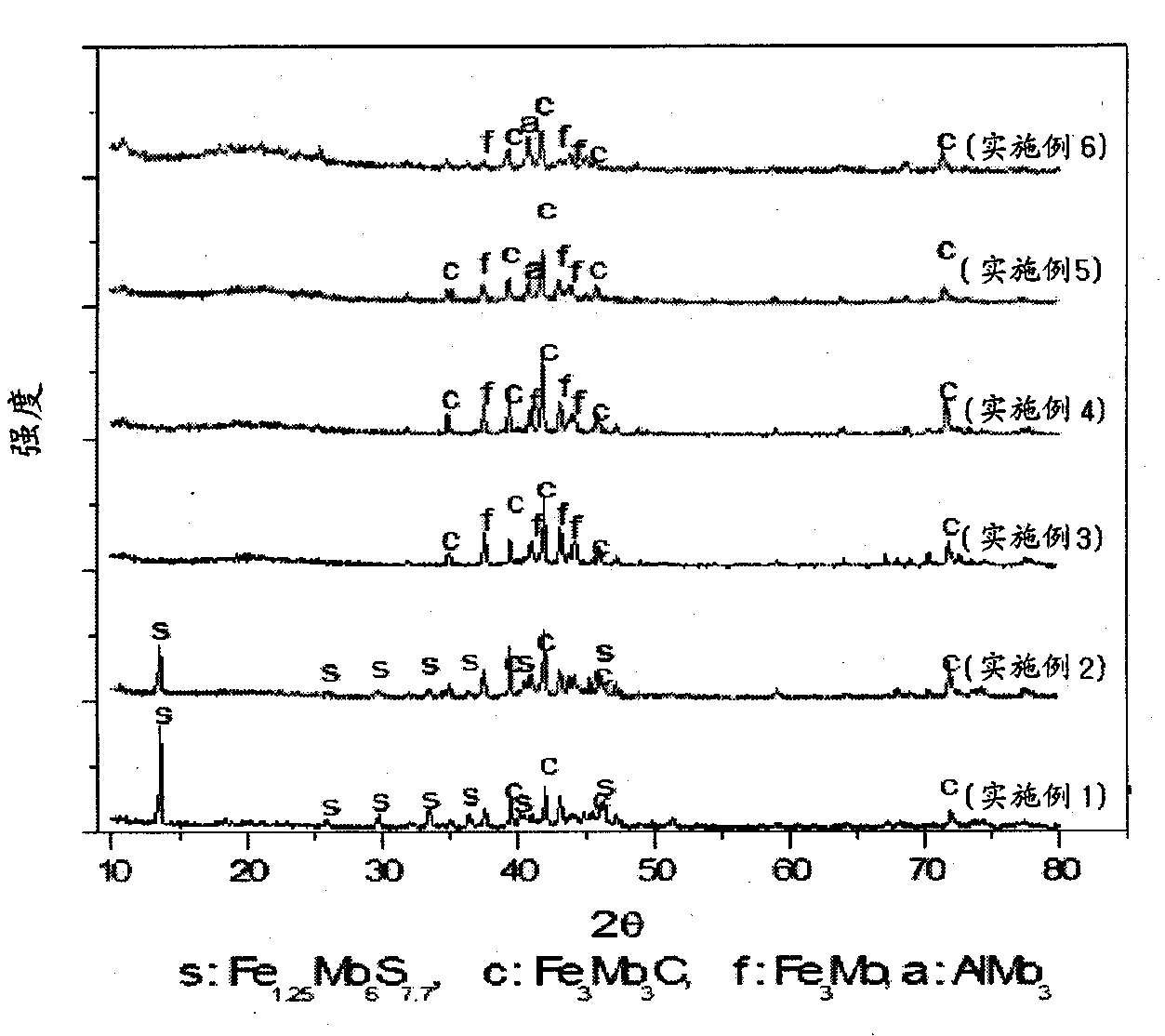

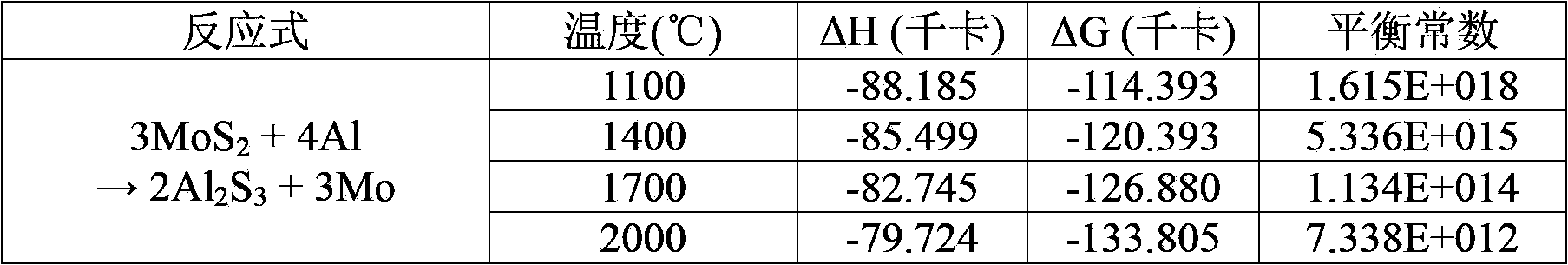

Method For Preparing Ferro Molybdenum From Molybdenite

The present invention relates to preparing ferro molybdenum from molybdenite concentrate, and more particularly, to a method for directly preparing ferro molybdenum having copper content of 0.5% or less from molybdenite with high copper content, without involving a separate process of eliminating copper, by inserting iron in a heating furnace and reacting same at a high temperature to prepare ferro molybdenum on the lower portion, and slag with aluminum sulfide and iron sulfide as main ingredients on the upper portion, so as to have most of the copper (80-95%) in the molybdenite exist in the slag layer. Compared to the existing thermite reaction, the present invention is advantageous in terms of a shorter process and reduced consumption of aluminum, which is a reducing agent.

Owner:KOREA INST OF GEOSCI & MINERAL RESOURCES

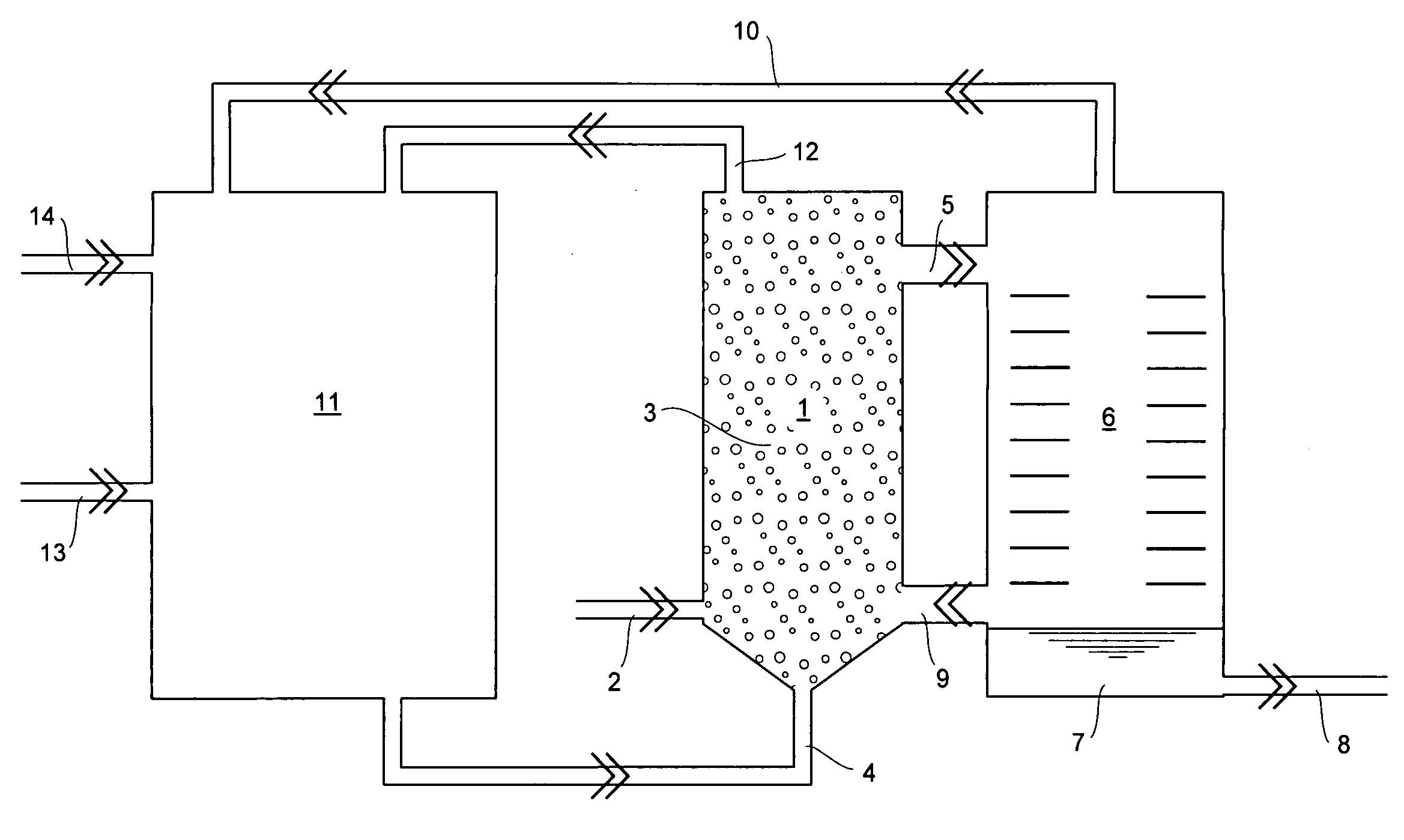

Super oxidation, coagulation and flocculation system for treatment of water and wastewater

ActiveUS8597507B2Prevent escapeLiquid degasificationMixing methodsChemical treatmentPotassium permanganate

The super oxidation, coagulation and flocculation system is applicable to water and wastewater chemical treatment in which oxidation, coagulation and flocculation processes take place in a single vessel.The apparatus and process can be used for treatment of domestic and industrial water and wastewater for removal of organic and inorganic contaminants.The oxidation process can be provided by several oxidizing chemicals such as ozone, hydrogen peroxide, potassium permanganate, chlorine and Ultra Violet Lights, and the coagulation process can be accomplished with several coagulants such as aluminum sulphide, ferric chloride, ferric sulphate.Selection of the chemicals depends on the quality of the water or wastewater to be treated and the treated water quality required, and it covers a wide range of impurities to be removed and specifically difficult to oxidize hydrocarbons and chlorinated organics, and iron, manganese, uranium, arsenic, cyanide, hydrogen sulphide.The apparatus and the process are economical and have a small installation footprint as several processes take place in a single vessel.

Owner:KORZENIOWSKI JAN A

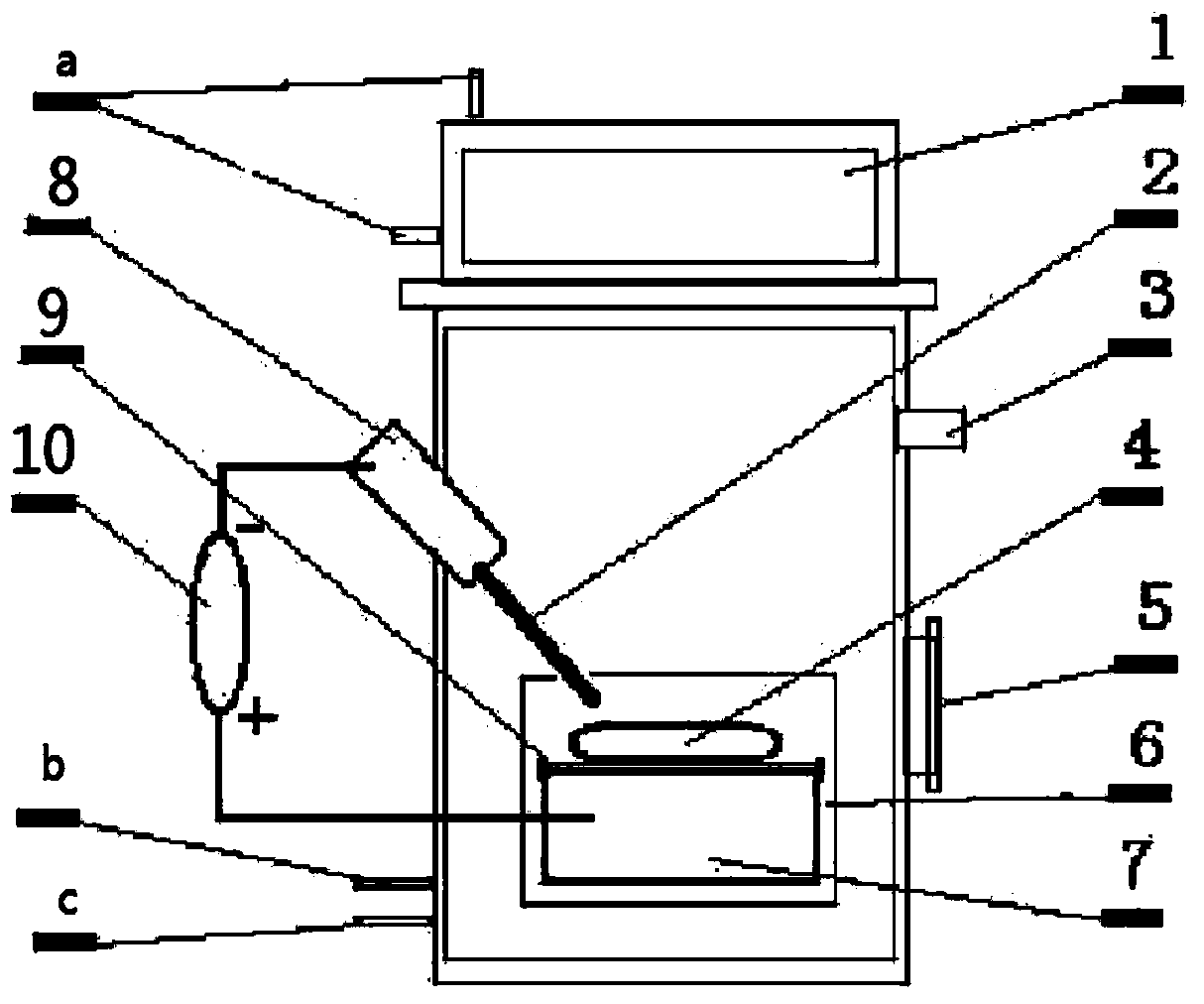

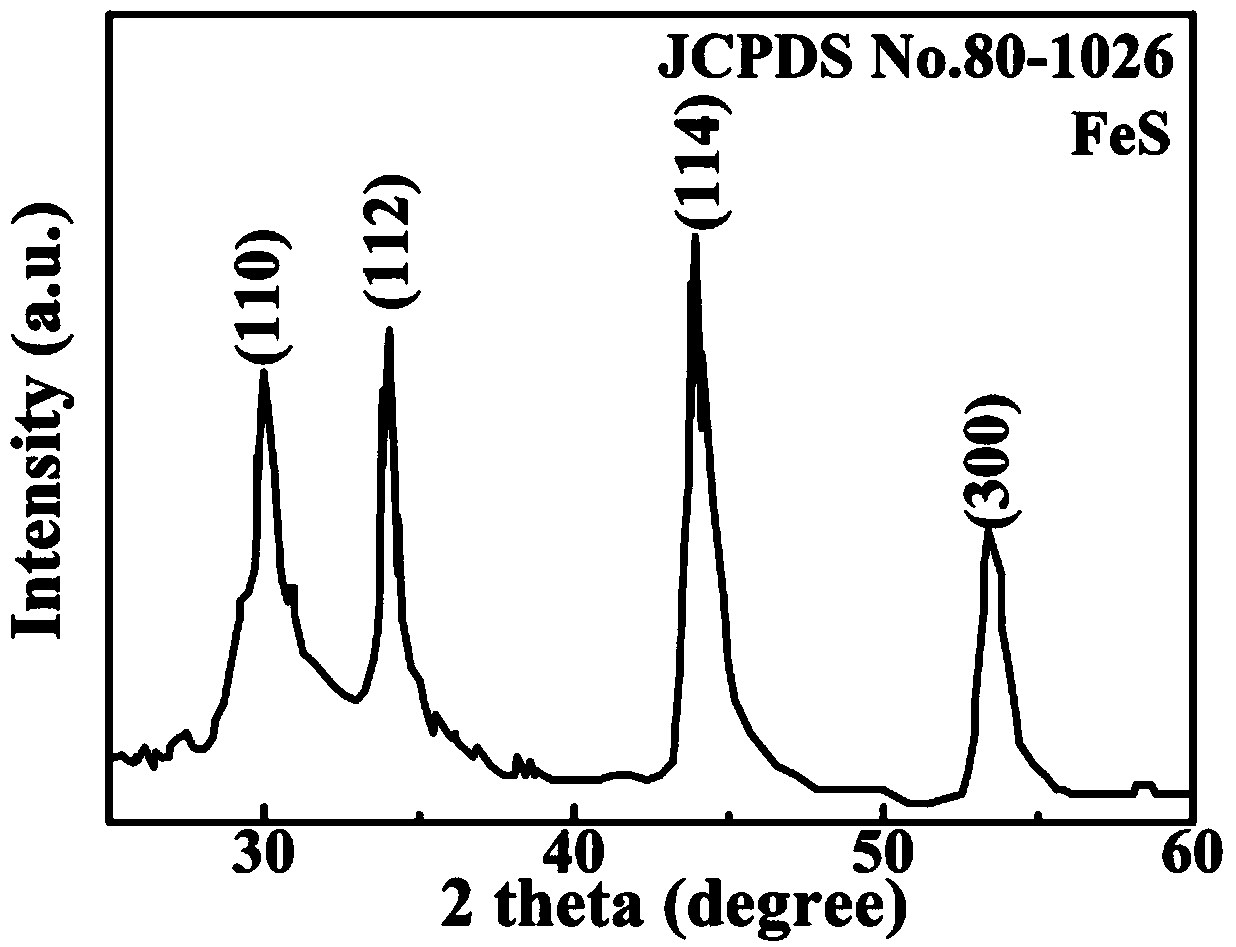

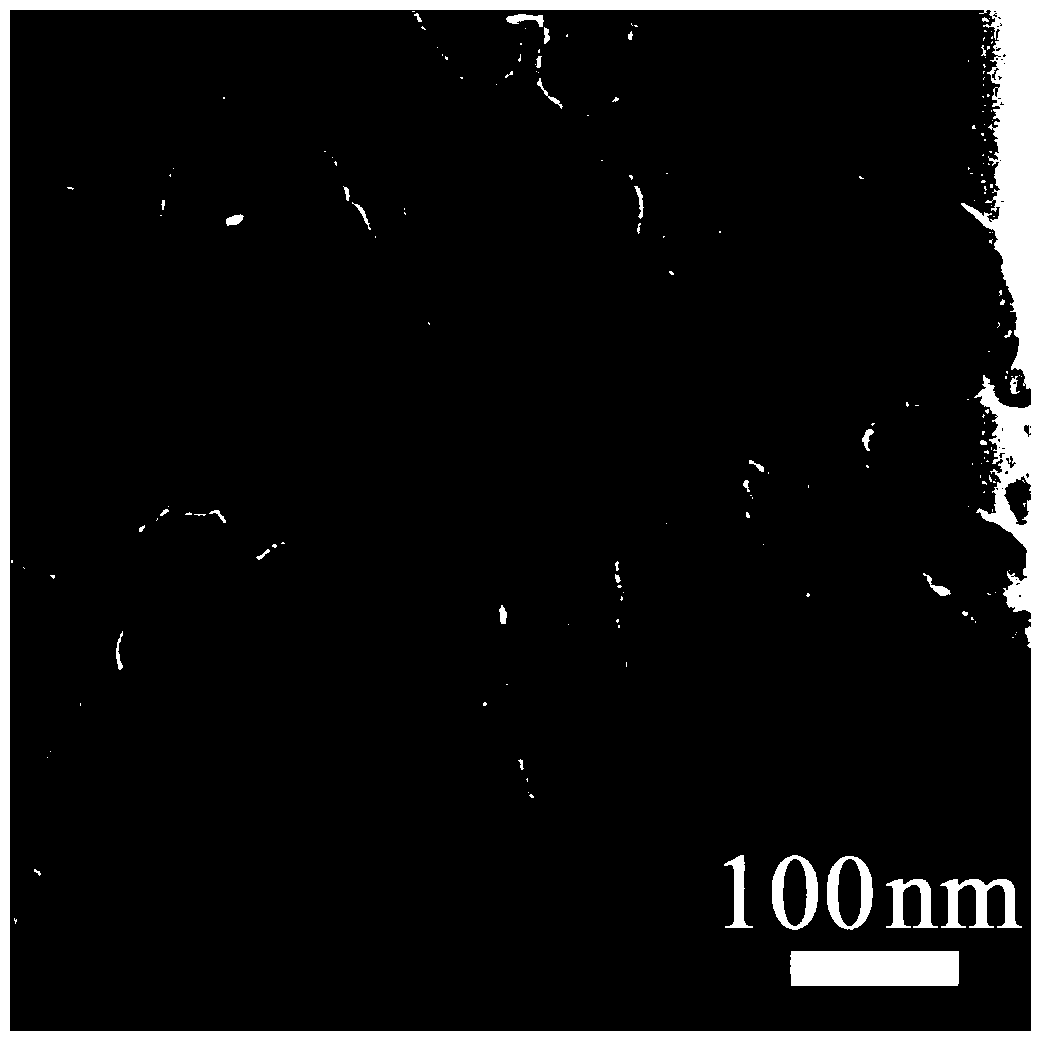

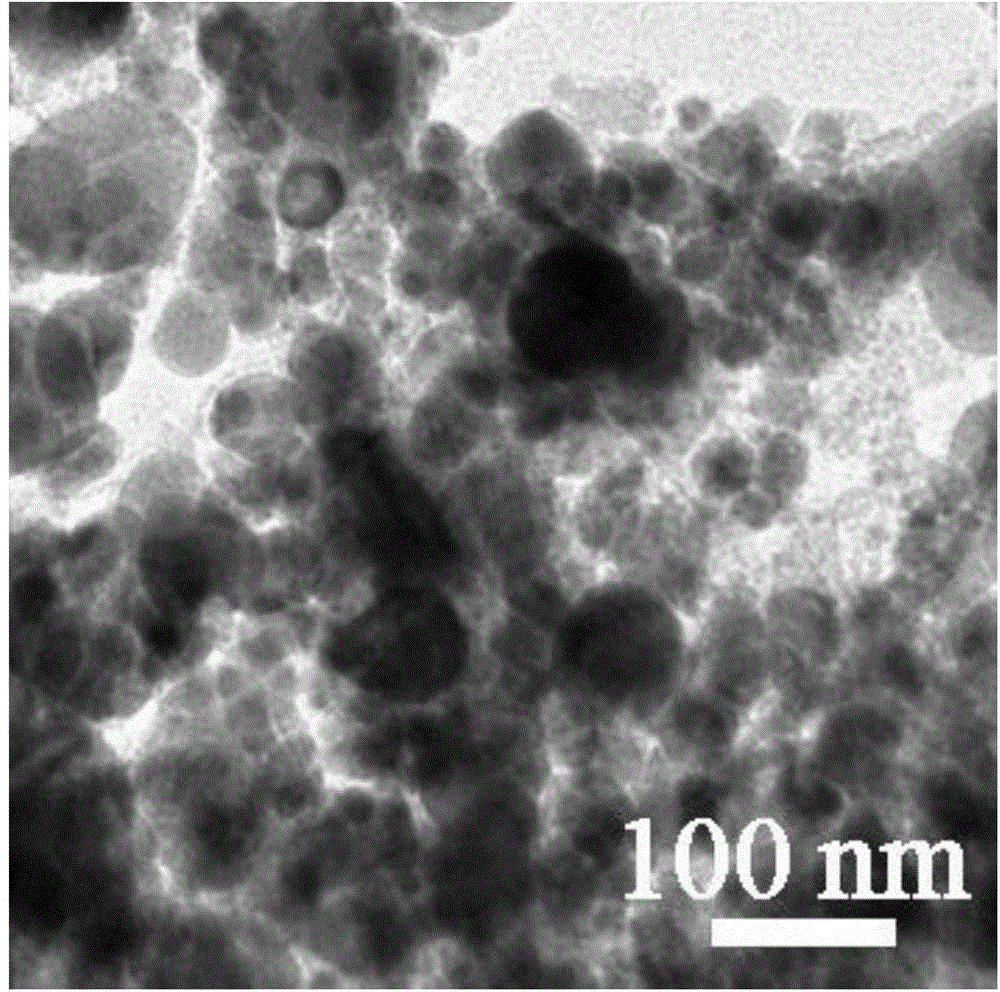

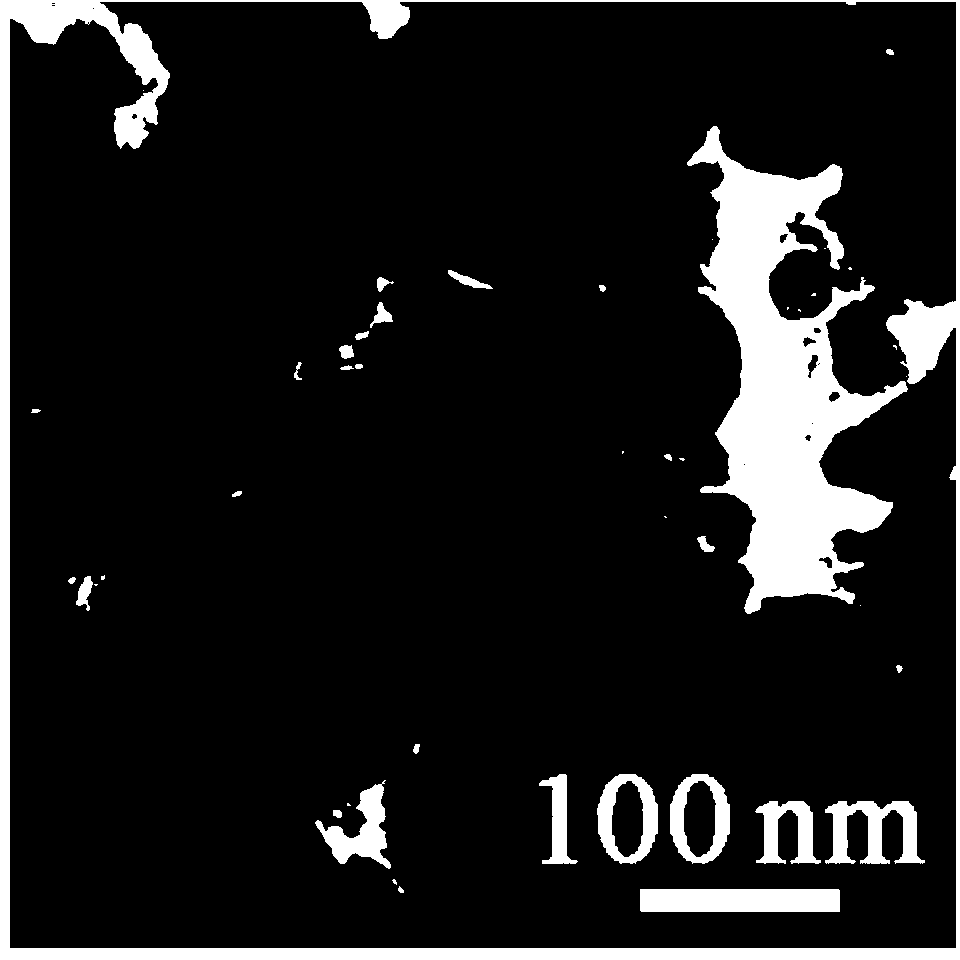

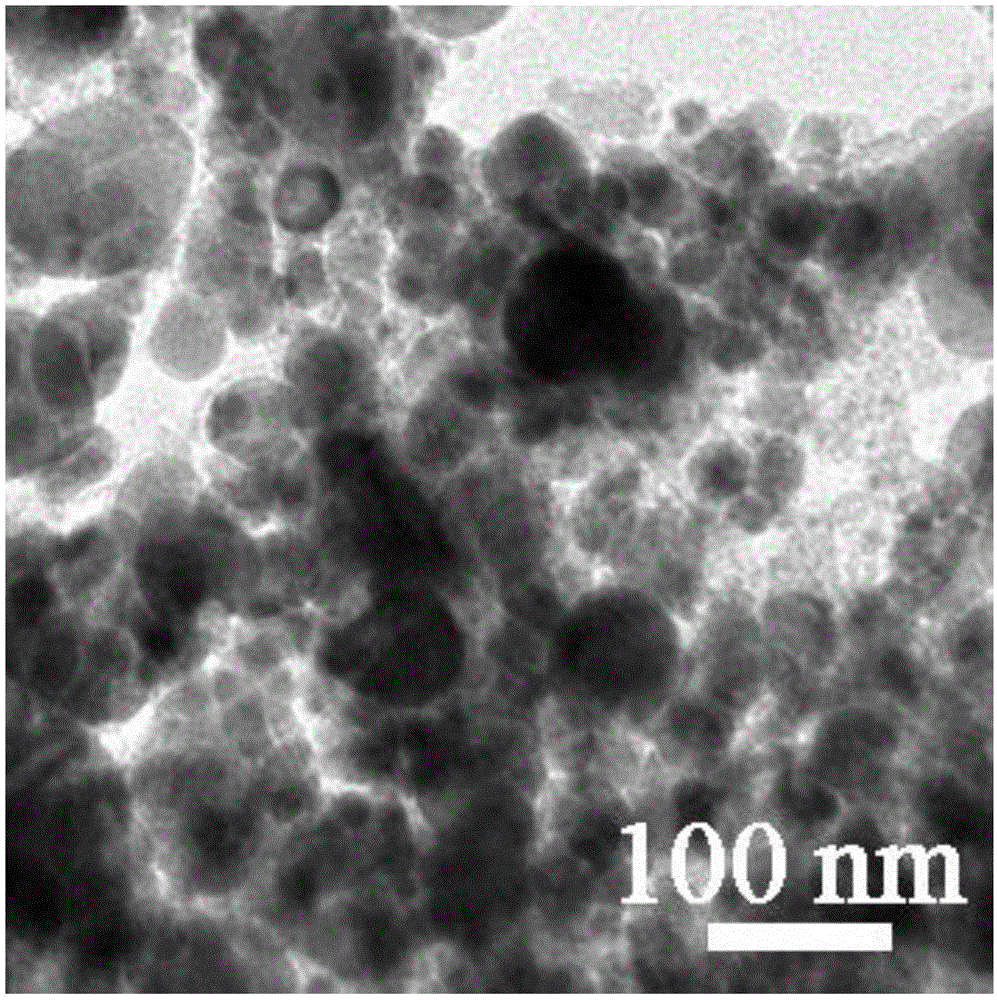

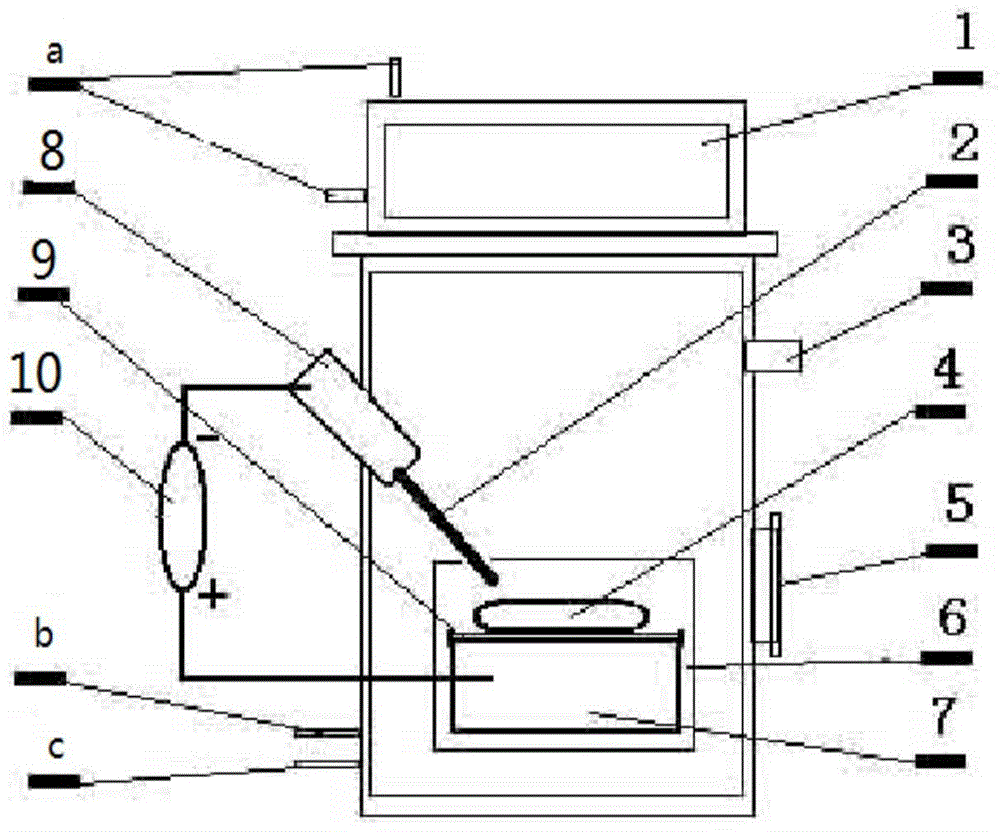

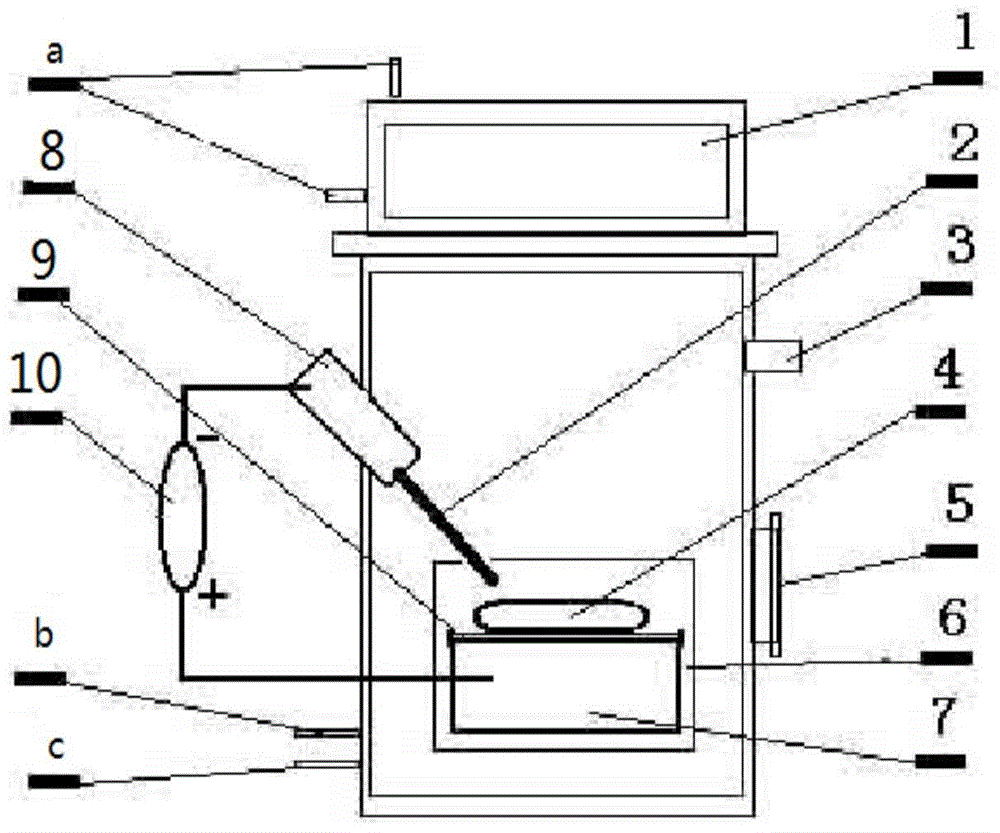

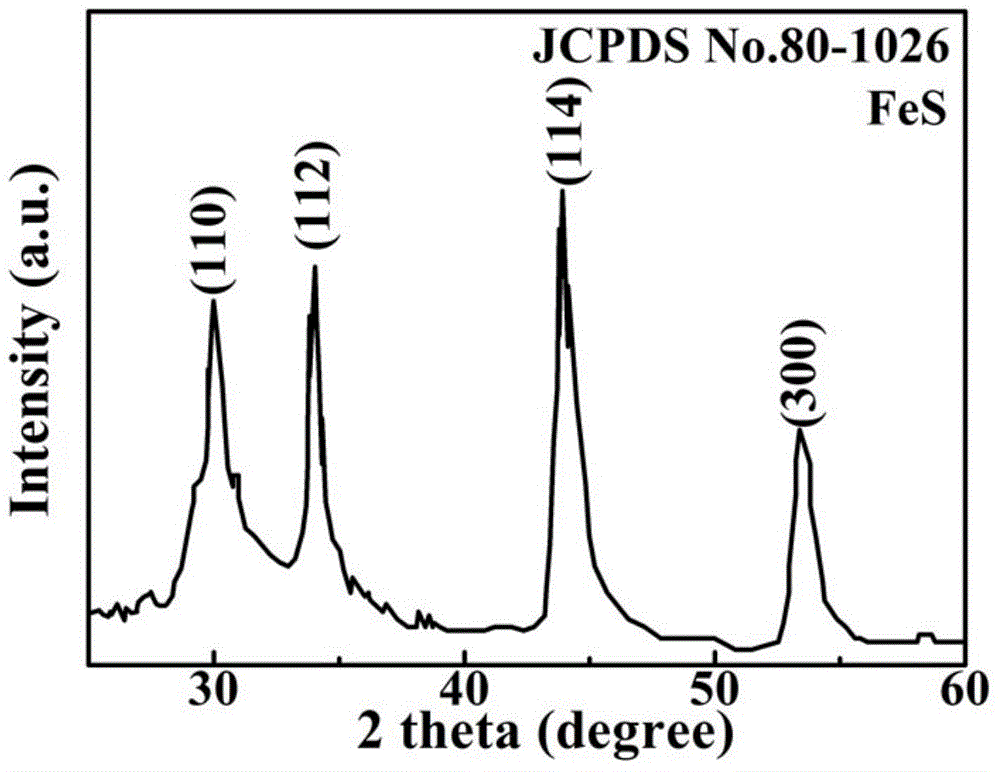

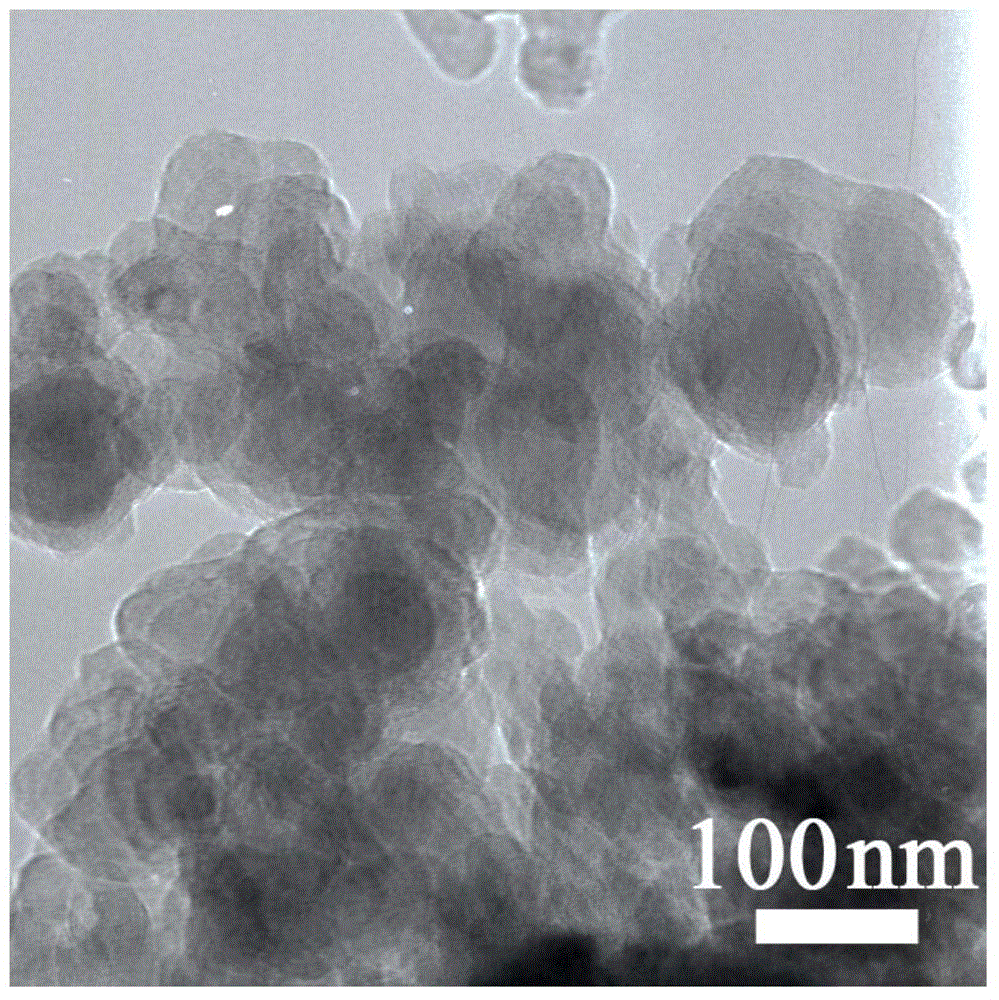

Ferrous sulfide nanometer powdered material with aluminium sulfide casing and preparation method thereof

InactiveCN104386765ASimple preparation conditionsEasy to controlMaterial nanotechnologyIron sulfidesNanomaterialsNanometer particle

The invention discloses a ferrous sulfide (FeS) nanometer powdered material with an aluminium sulfide (Al2S3) casing and a preparation method thereof, and belongs to the technical field of preparing nanometer materials. The nanometer powdered material is in a core-shell structure, a kernel is an FeS nanometer particle, and the casing is an Al2S3 layer; the particle diameter of the FeS nanometer particle kernel is 10-100 nm, and the Al2S3 casing layer is an amorphous Al2S3 layer of which the thickness is 1-10 nm. According to the invention, a plasma arc discharge method is adopted, according to a certain atomic percent, ferrous powder and aluminium powder are pressed into a block which is used as an anode material, a graphite is used as a cathode material, an argon gas and a hydrogen sulfide gas are used as a work gas, a certain distance is kept between a cathode and an anode, and arc discharge is generated between the cathode and the anode, so that the FeS nanometer powdered material with the Al2S3 casing is obtained. The preparation process of the ferrous sulfide nanometer powdered material is simple, post-processing working procedures are avoided, and the cost is low, so that industrialized production is easy to realize.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Li2S-Al2S3 solid electrolyte material for secondary lithium cell and its preparing method

ActiveCN100486025CRich structure typeImprove ionic conductivityFinal product manufactureSecondary cells manufactureAll solid stateChemical physics

Characters of the invention are that materials of solid electrolyte Li : Al : S=1 :1 :2 (at mol ratio) are amorphous material. Aluminum sulphide is as framework of providing transmission space for lithium ion so as to obtain higher ionic conductivity (ionic conductivity in room temperature about 1.77*10-5S / cm), lower electron conductivity (electron conductivity in room temperature less than 1.0*10-8S / cm), lower activation energy of material, and wider thermostable range. The invention provides comparative ideal candidate of electrolyte material for practical lithium ion battery in full solid state.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Preparation method of epoxy resin adhesive special for offshore wind power blades

InactiveCN103709982AGood weather resistanceNon-macromolecular adhesive additivesEster polymer adhesivesPolymer scienceVulcanization

Owner:ALPHA ESS CO LTD

Method for preparing macroporous aluminium sulfide/aluminium oxide mercury removal agent

ActiveCN109126413AReduce over-sinteringPrevent over-sinteringGas treatmentDispersed particle separationPhosphoric acidMoisture

The invention provides a method for preparing a macroporous aluminium sulfide / aluminium oxide mercury removal agent. The method includes the steps of (1), mixing Rho-alumina powder, pseudo-boehmite dry powder and lubricant uniformly, adding solution containing phosphoric acid and ammonium dihydrogen phosphate, mixing, extruding and drying; (2), roasting the dry rods at the temperature of 950-1050DEG C to obtain an aluminum oxide carrier; (3), subjecting the aluminum oxide carrier to hot dipping in sodium polysulfide solution, standing in a closed and thermal-insulating environment, performingpurging of carbon dioxide, washing, and then drying at the temperature lower than 80 DEG C, so as to obtain the mercury removal agent. The mercury removal agent prepared by the method has high mercury removal precision and high capacity, taking off of powder is not easy to cause during long-term use, mercury removal precision and capacity is not affected by moisture and easy-to-coagulate hydrocarbon of materials, service cycle of the mercury removal agent is long, and changing frequency is low, and besides, the process that aluminum oxide carries sulphur is easy to control, and distribution of sulphur is uniform.

Owner:山东迅达化工集团有限公司

Concrete curing agent

A concrete curing agent is prepared from the following raw materials in parts by weight: 9-11 parts of aluminium sulfide, 5-8 parts of chlorosulfonated polyethylene, 3-9 parts of industrial soap, 5-8 parts of ethanol, 7-10 parts of lauryl sodium sulfate, 5-7 parts of seconda-grade fly ash, 7-11 parts of 4-isooctyl phenol, 6-8 parts of corn protein powder, 3-9 parts of dehydroacetic acid, 4-8 parts of sodium tripolyphosphate, 2-5 parts of hydrochloric acid, 9-16 parts of methyl methacrylate, 3-8 parts of divinyl benzene, 5-10 parts of ammonium persulfate and 4-11 parts of ethylene glycol. The beneficial effects of the concrete curing agent are that, the concrete curing agent can be high-efficiency, water-saving, and convenient in construction, can be used in large area, and can be widely used in airports, highways, buildings and other aspects.

Owner:张桂华

Concrete crack resistance modifier

InactiveCN103641350AGood low temperature stabilityGuaranteed low temperature stabilityCrack resistanceRoad surface

The invention discloses a concrete crack resistance modifier, which is prepared by the following raw materials by weight: 2.5-3.7 parts of aluminium sulfide, 1.3-2.6 parts of magnesium oxide, 0.5-1.6 parts of naphthalene water reducer, 2.3-4.6 parts of gum acacia, 2.5-4.5 parts of chlorosulfonated polyethylene, 1.2-1.8 parts of ammonium thiosulphate, 1.6-5.8 parts of carboxylated styrene-butadiene latex and 1.2-3 parts of ethylene propylene terpolymer. Compared with the prior concrete modifier, the product has the advantages of high surface toughness, low brittleness and improved low-temperature stability; the produced concrete has the advantages of decreased heat conduction coefficient, reduced heat absorption value, improved thermal resistance and cold resistance, reduced temperature sensitivity, improved high and low-temperature stability, thereby improving crack resistance performance of the concrete pavement road, increasing usage time limit of the pavement, and reducing maintenance cost.

Owner:QINGDAO HUIERTONG TRADING

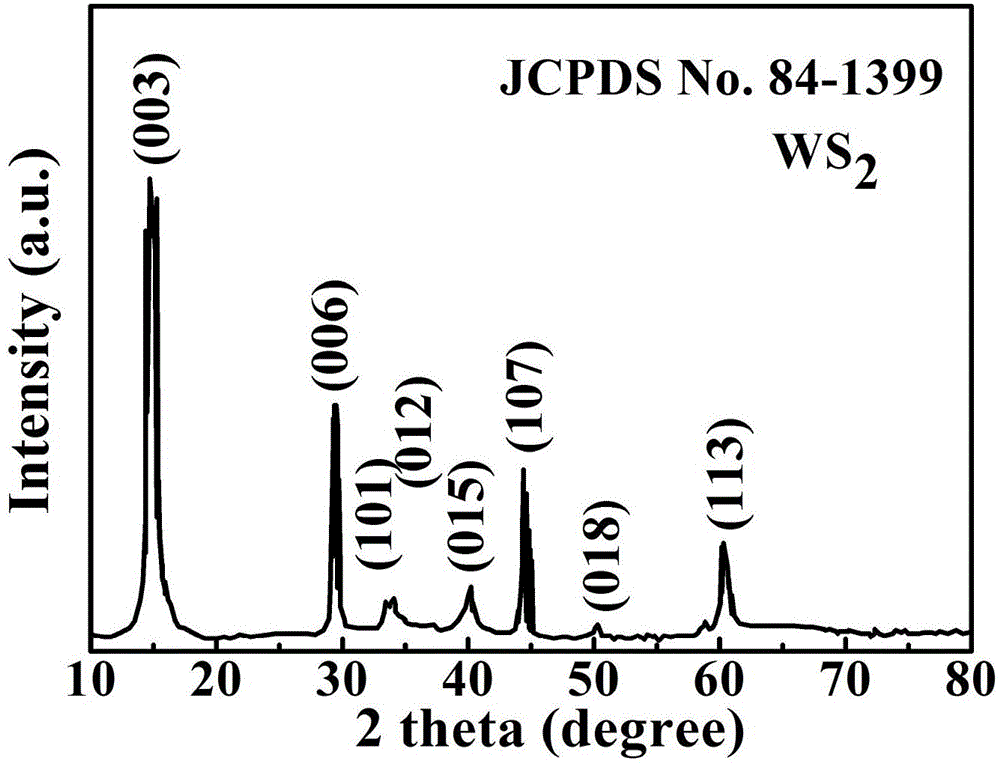

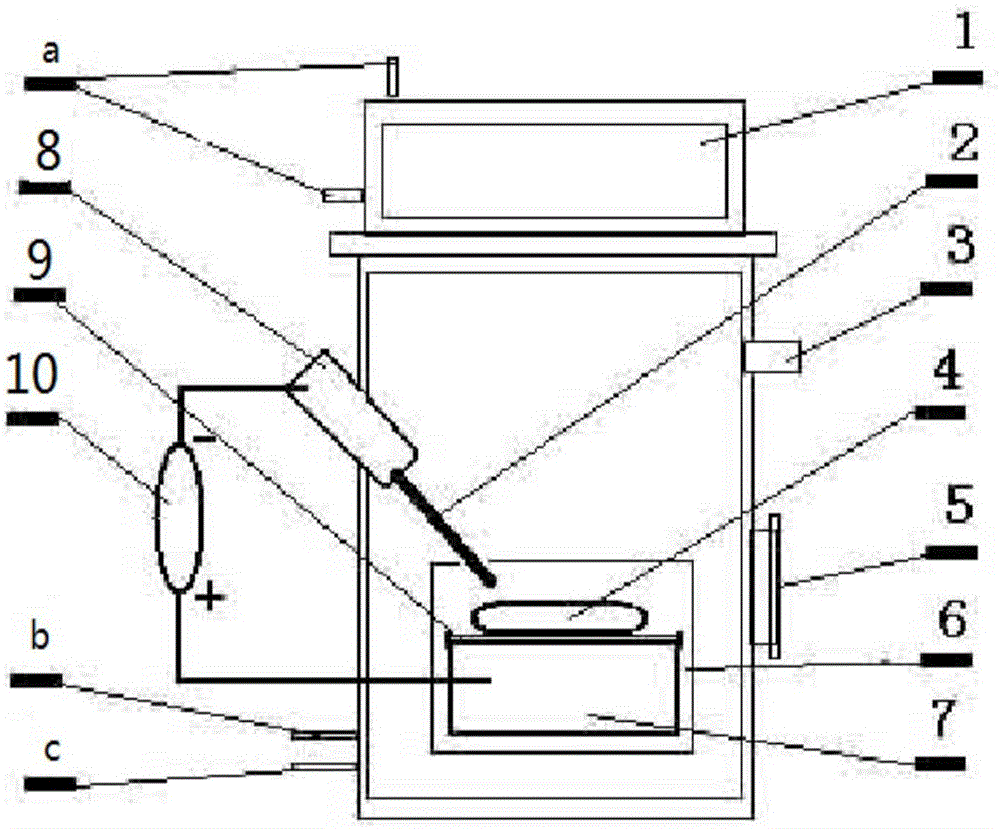

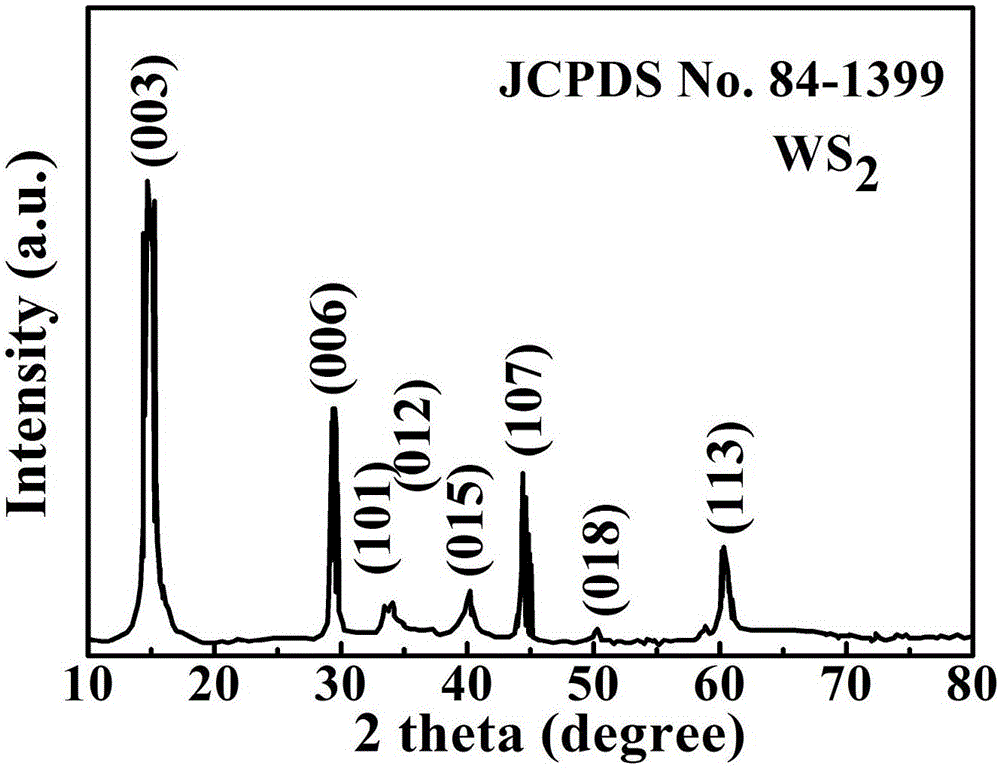

Tungsten disulfide nano powder material with aluminum sulfide shell, and preparation method of tungsten disulfide nano powder material

ActiveCN104310485ASimple preparation conditionsEasy to controlMaterial nanotechnologyAluminium sulfidesGraphiteAluminium sulfide

The invention discloses a tungsten disulfide (WS2) nano powder material with an aluminum sulfide (Al2S3) shell, and a preparation method of the WS2 nano powder material, belonging to the technical field of preparation of nano materials. The nano powder material has a core-shell structure, wherein the inner core of the core-shell structure is WS2 nano-particles, and the shell of the core-shell structure is an Al2S3 layer; the inner core of the WS2 has the particle sizes of 10-100nm, and the Al2S3 shell layer is an amorphous Al2S3 layer and has the thickness of 1-10nm. According to the preparation method, tungsten powder and aluminum powder are pressed into a block according to a certain atomic percent by a plasma arc discharge method, and the block is taken as an anode material; graphite is taken as a cathode material; argon and hydrogen sulfide are taken as working gases; a certain distance is maintained between the cathode and the anode, and arc discharge is realized between the cathode and the anode, so that the WS2 nano powder material with the Al2S3 shell can be obtained. The preparation process is simple, the working procedure of aftertreatment is not needed, the cost is low, and industrial production can be easily realized.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

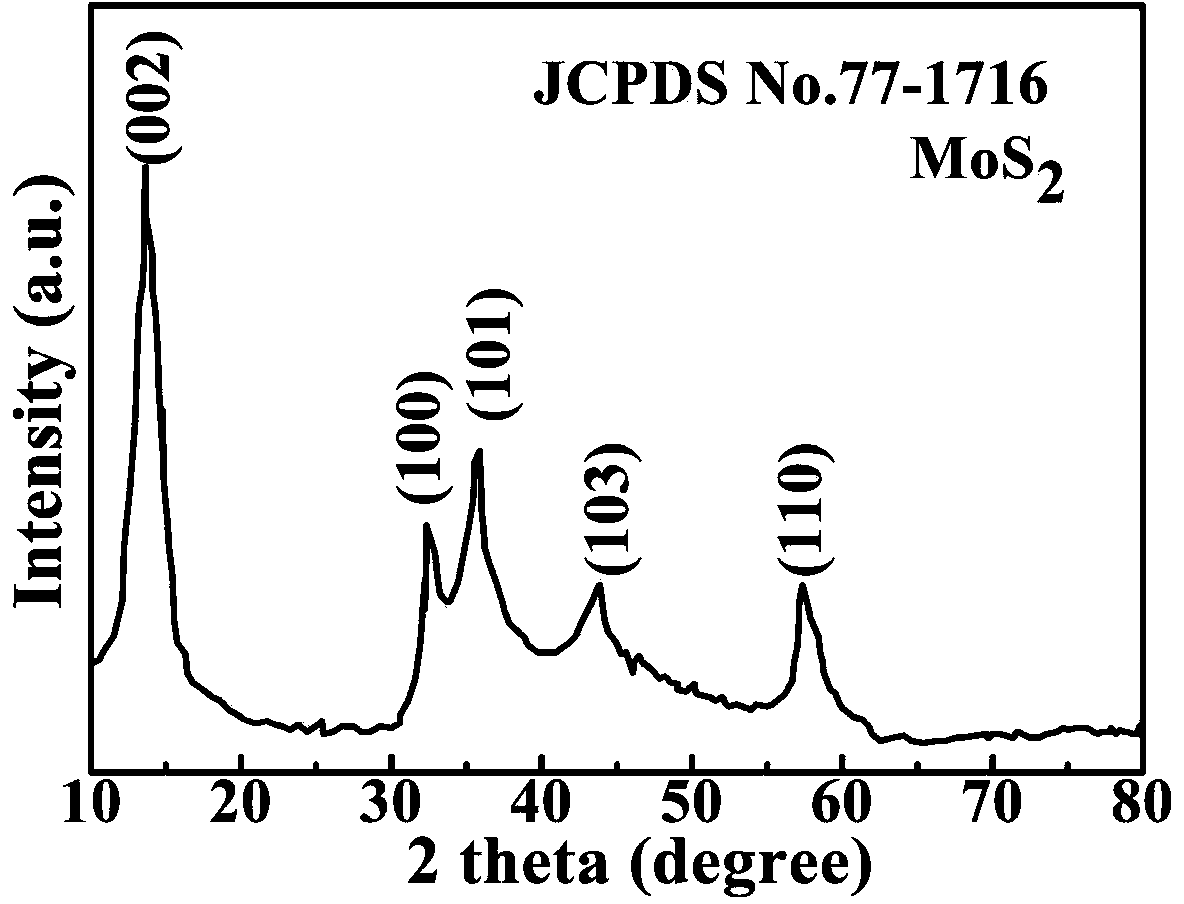

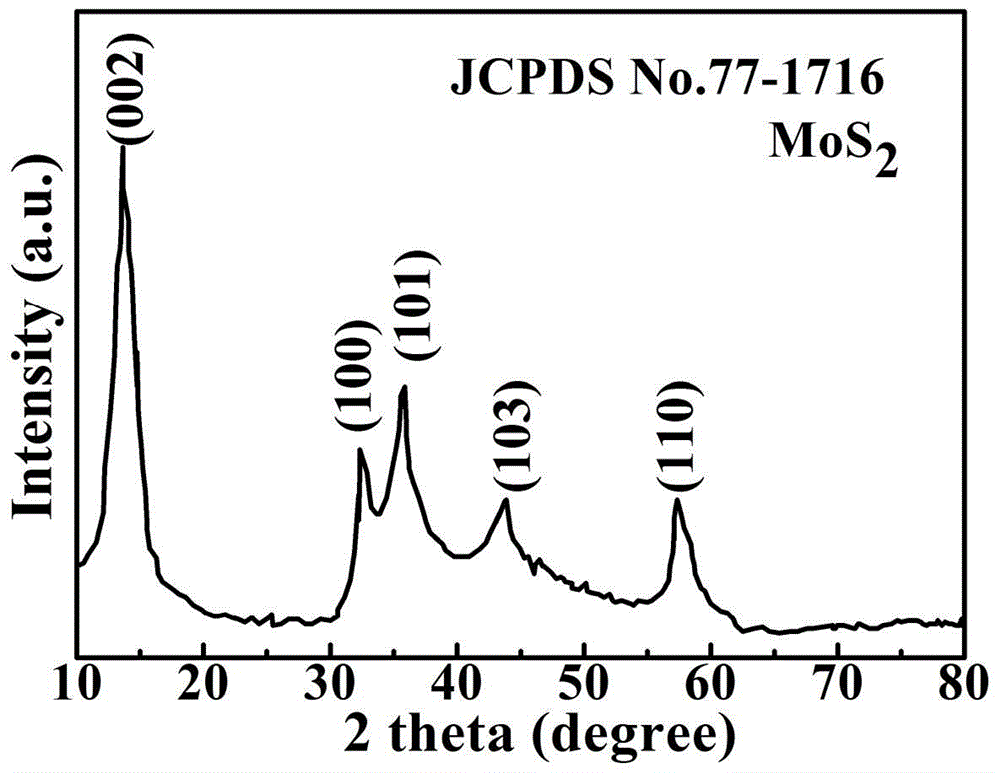

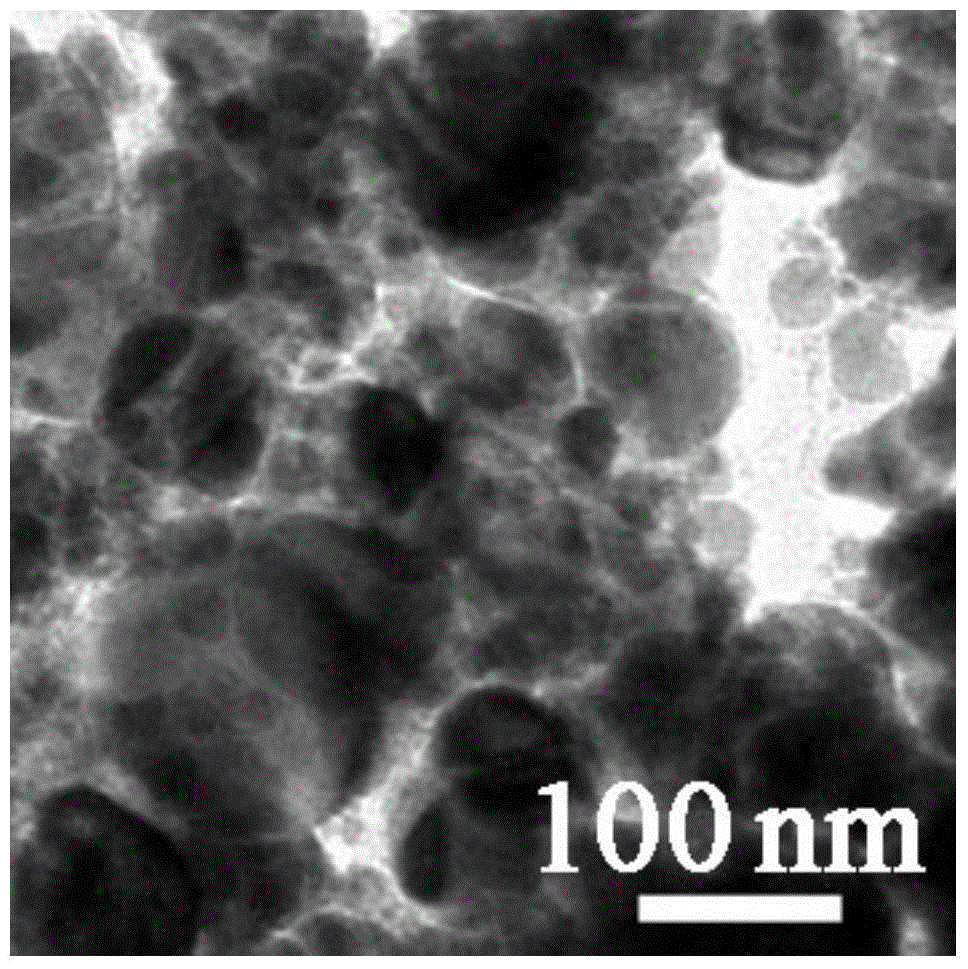

Molybdenum disulfide nanometer powder material with aluminum sulfide housing and preparation method of molybdenum disulfide nanometer powder material

ActiveCN104347876ASimple preparation conditionsEasy to controlCell electrodesMolybdenum sulfidesGraphiteAluminium sulfide

The invention discloses a molybdenum disulfide nanometer powder material with an aluminum sulfide housing and a preparation method of the molybdenum disulfide nanometer powder material, belonging to the technical field of preparation of nanometer materials. The nanometer powder material is of a core-shell structure, an MoS2 nanometer particle is used as an inner core, an Al2S3 layer is used as a housing; the particle size of the MoS2 inner core is 10nm-100nm, the Al2S3 housing layer is an amorphous Al2S3 layer and has a thickness of 1nm-10nm. According to the molybdenum disulfide nanometer powder material, by adopting a plasma arc discharge method, molybdenum powder and aluminum powder are briquetted into a block body according to a certain atomic percent to be used as an anode material, graphite is used as a cathode material, argon and hydrogen sulfide gases are introduced to be used as working gases, a certain distance is kept between a cathode and an anode, and arc discharge is achieved between the cathode and the anode, so that the MoS2 nanometer powder material with the Al2S3 housing is obtained. The preparation method is simple in preparation process, free from posttreatment procedure and low in cost; industrialized production is easily realized.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

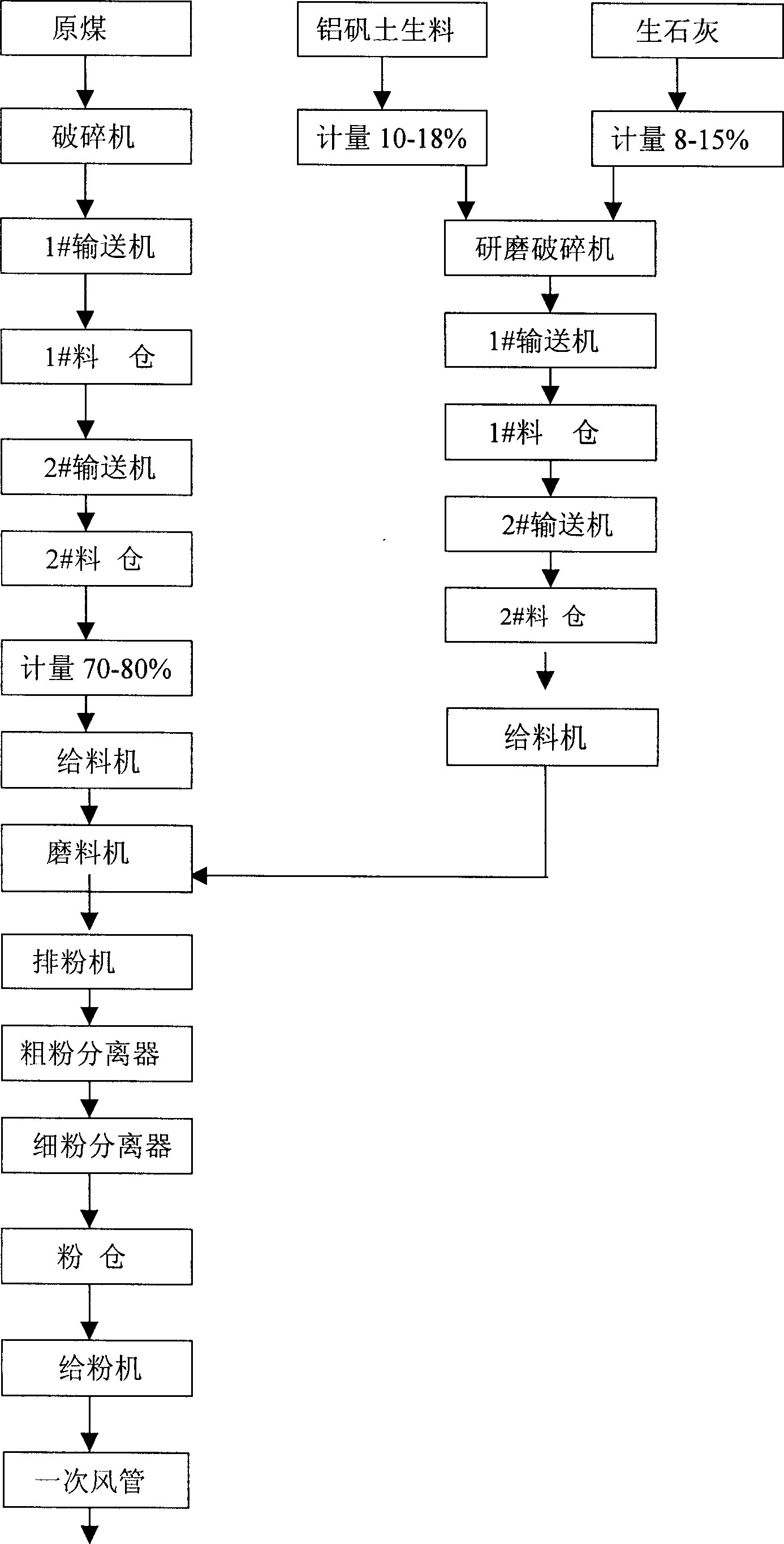

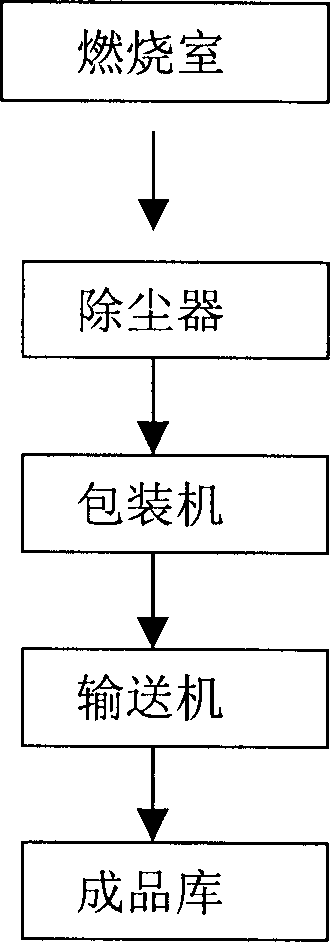

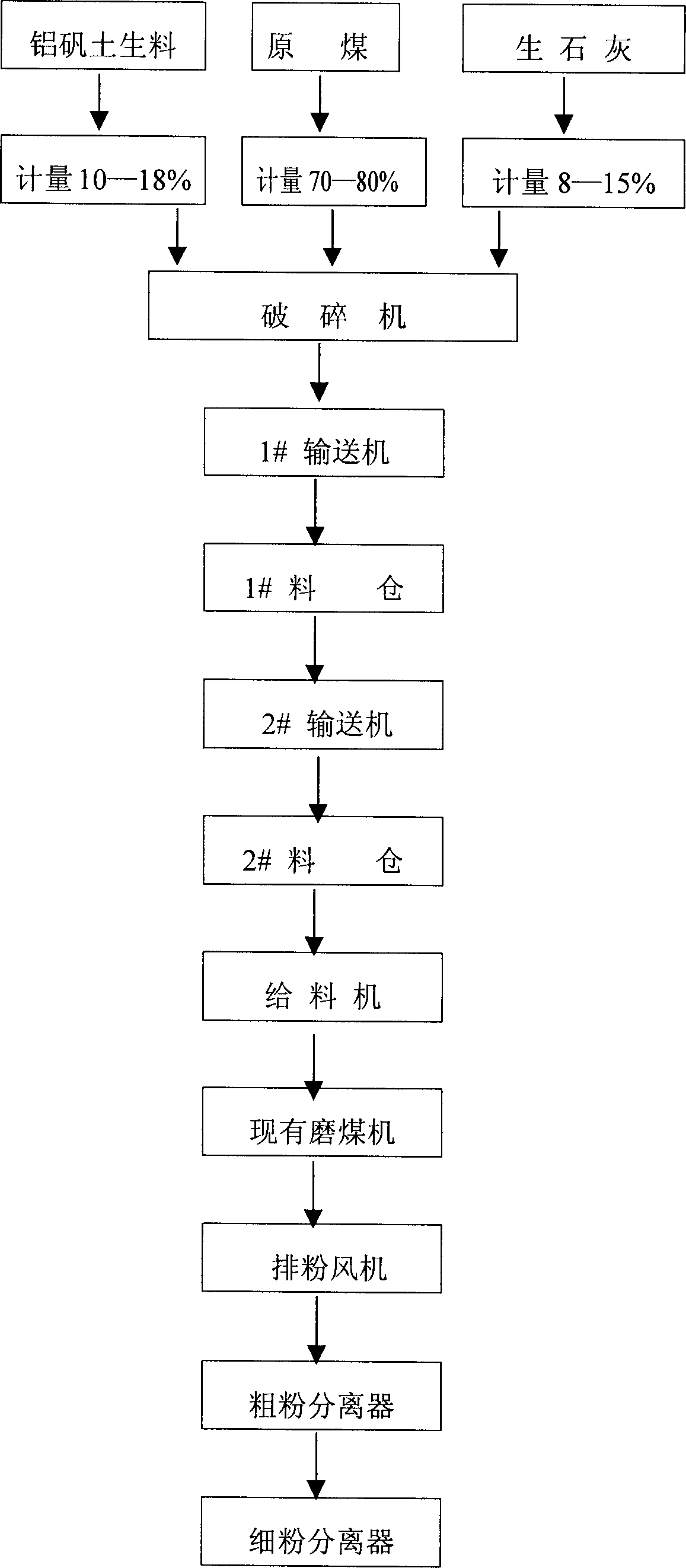

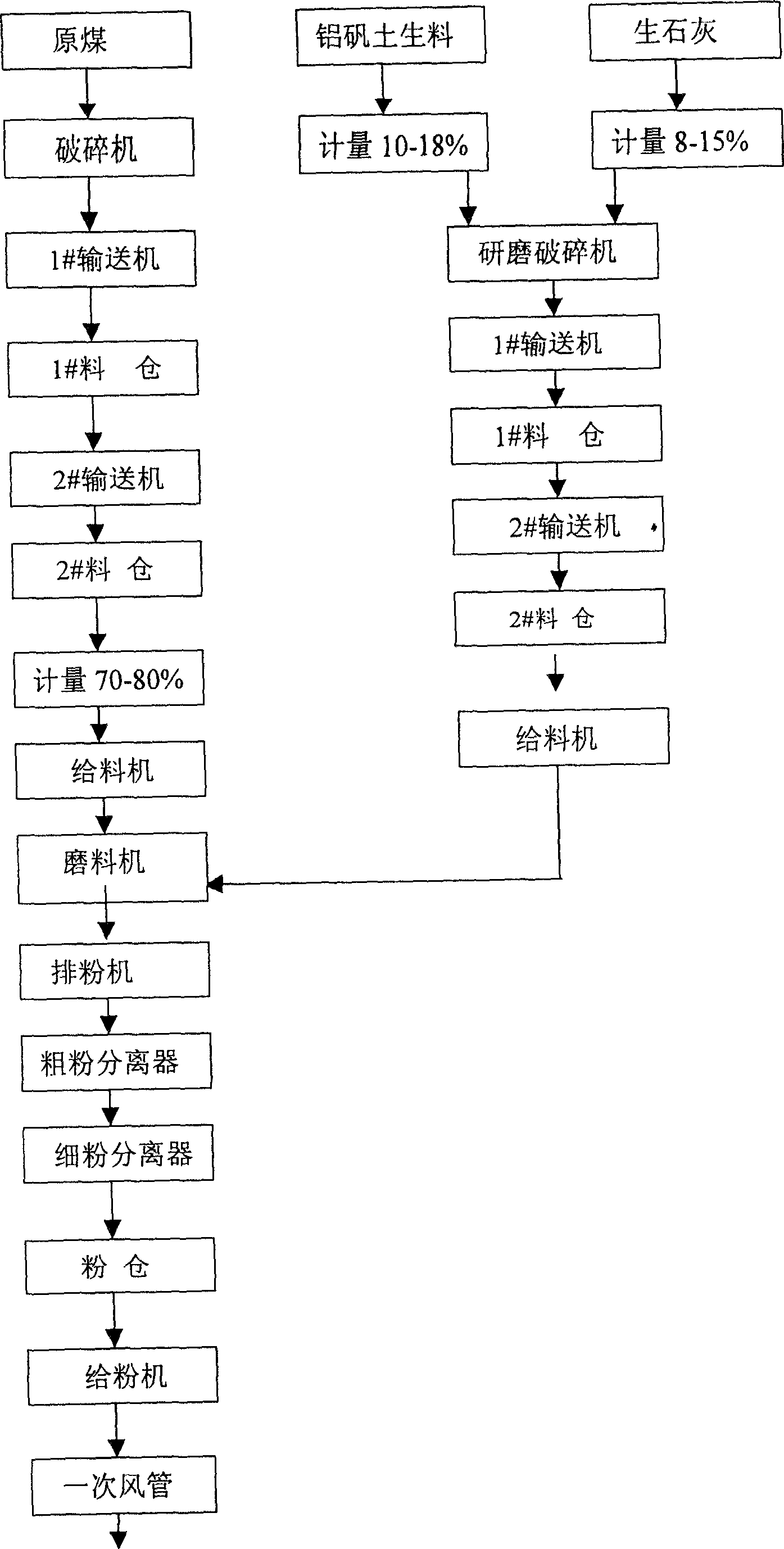

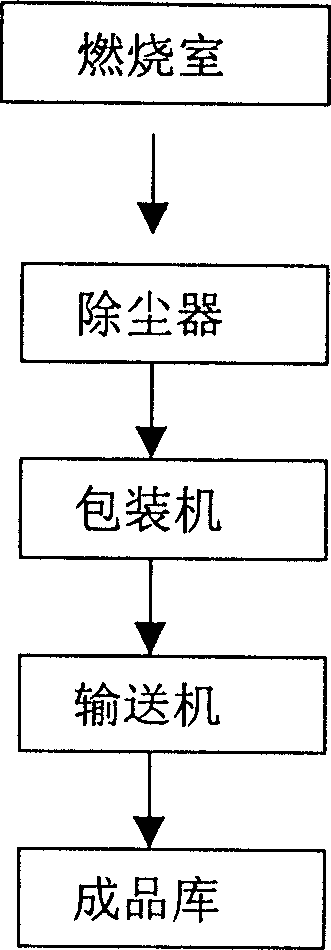

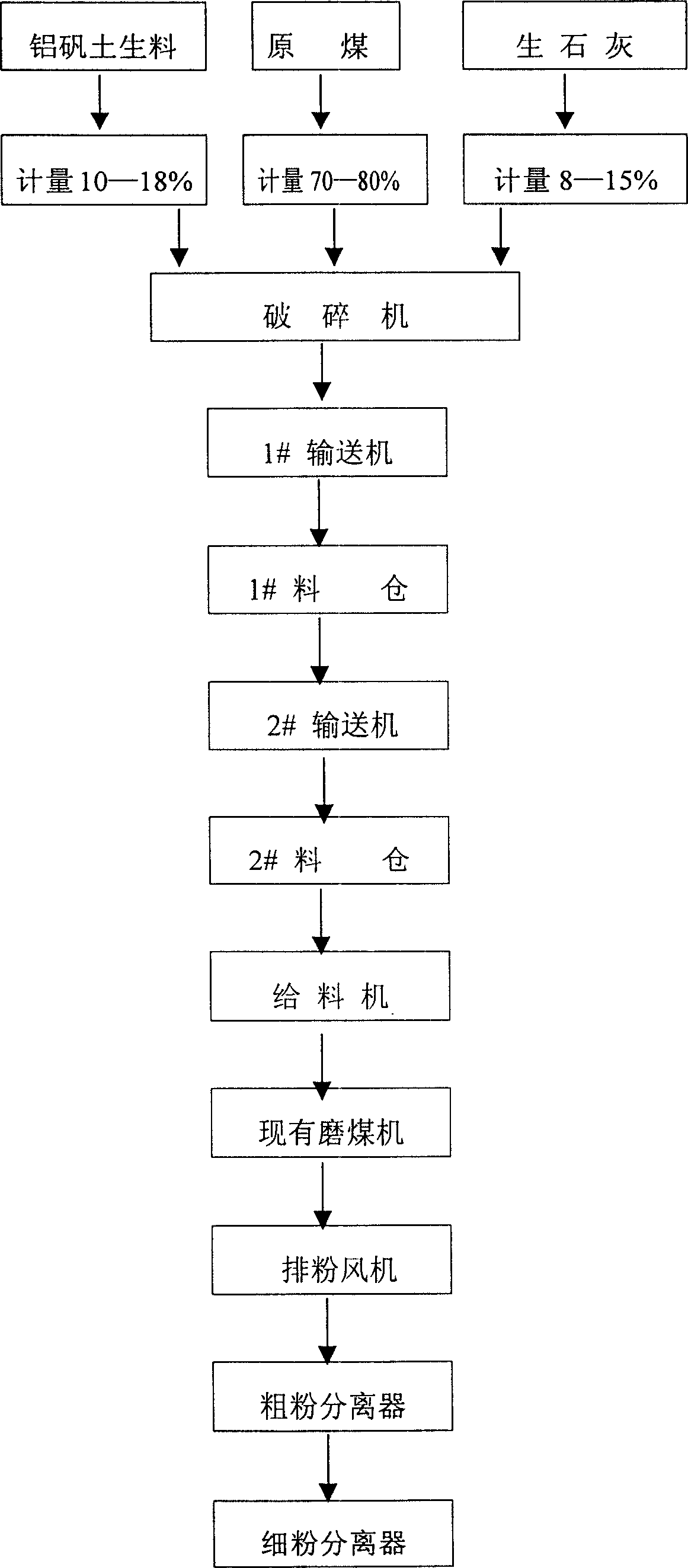

Method of concurrently burning aluminate, bauxite and aluminium sulfide gel material for generating boiler

The invention relates to a method for producing gelatinization materials of aluminate, ferroaluminate and thioaluminate by using power generation boiler, which it is characterized by that 70-80% of raw coal, 10-18% of bauxite raw material and 8-15% of caustic lime are mixed, ground and homogenized, then the obtained mixed material is fed into powder-falling pipe, passed through air passage and fed into combustion chamber, after combustion the ash granules are passed through electrostatic precipitator to obtain the finished product, such as aluminate, ferroaluminate and thioaluminate gelatinization materials.

Owner:DENGFENG ELECTRICITY GRP

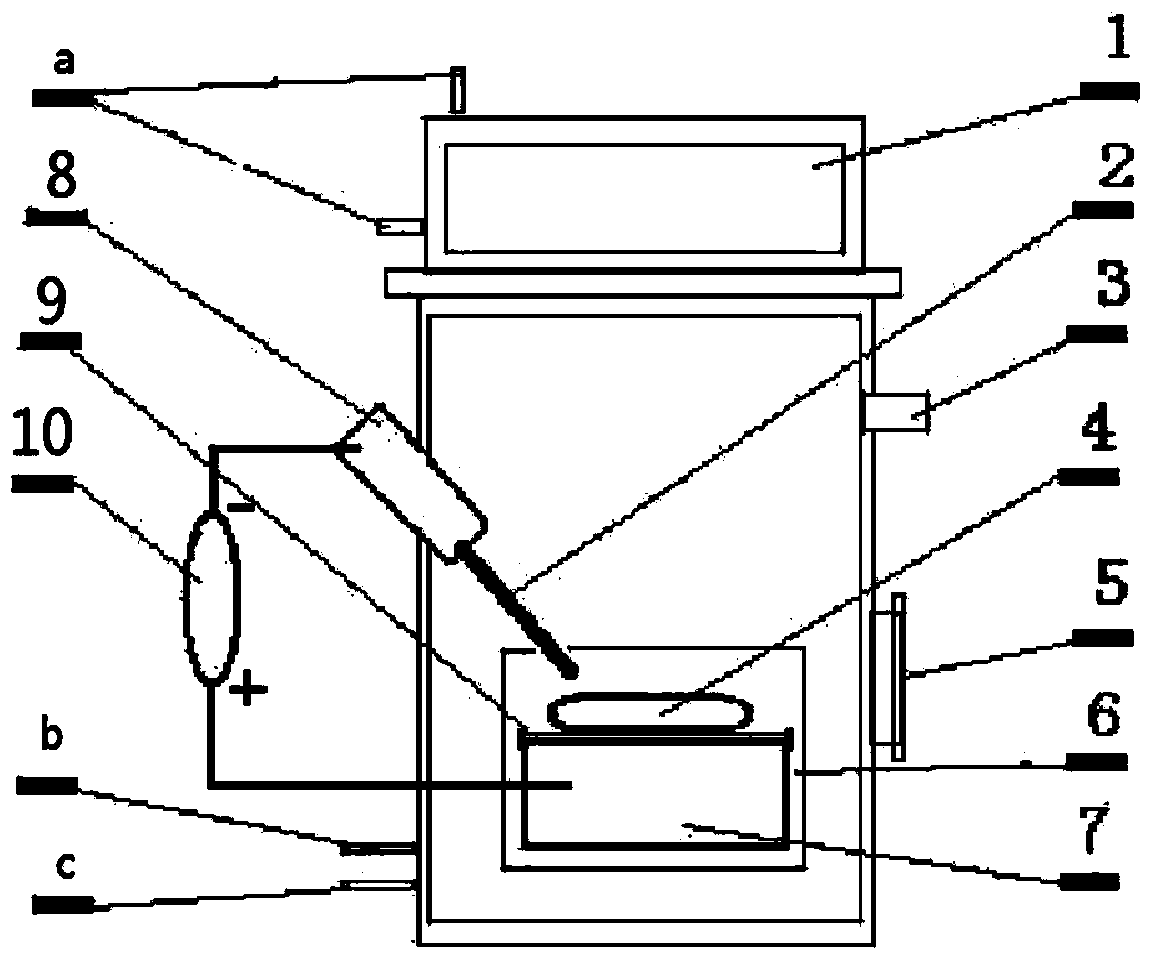

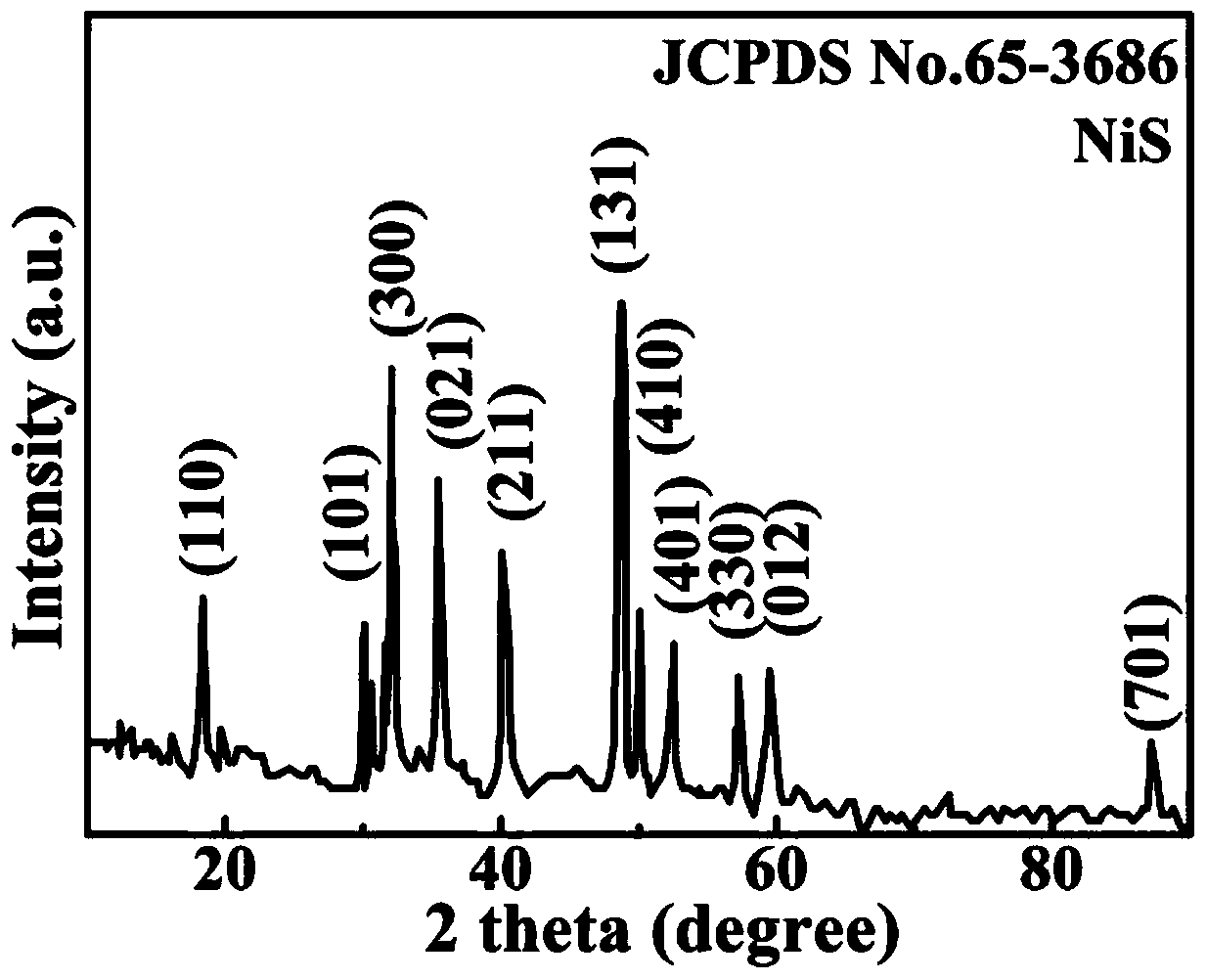

Nickel sulfide nanometer powdered material with aluminium sulfide casing and preparation method thereof

InactiveCN104386766ASimple preparation conditionsEasy to controlMaterial nanotechnologyAluminium sulfidesAluminium powderGraphite

The invention discloses a nickel sulfide (NiS) nanometer powdered material with an aluminium sulfide (Al2S3) casing and a preparation method thereof, and belongs to the technical field of preparing nanometer materials. The nanometer powdered material is in a core-shell structure, a kernel is an NiS nanometer particle, and the casing is an Al2S3 layer; the particle diameter of the NiS nanometer particle kernel is 10-100 nm, and the Al2S3 casing layer is an amorphous Al2S3 layer of which the thickness is 1-10 nm. According to the invention, a plasma arc discharge method is adopted, according to a certain atomic percent, nickel powder and aluminium powder are pressed into a block which is used as an anode material, a graphite is used as a cathode material, an argon gas and a hydrogen sulfide gas are used as a work gas, a certain distance is kept between a cathode and an anode, and arc discharge is generated between the cathode and the anode, so that the NiS nanometer powdered material with the Al2S3 casing is obtained. The preparation process of the nickel sulfide nanometer powdered material is simple, post-processing working procedures are avoided, and the cost is low, so that industrialized production is easy to realize.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method and apparatus for the production of aluminium

InactiveUS20060226026A1Improve efficiencySpeed up the conversion processPolycrystalline material growthElectrolysis componentsMolten saltAluminium sulfide

Disclosed is a method for the continuous production of aluminum from alumina including a first step of converting alumina (Al2O3) into aluminum sulfide (Al2S3) and a second step of separation of aluminum from aluminum sulfide in a separating reactor. Wherein in the first step in a conversion reactor alumina is dissolved in a molten salt to form a melt and a sulfur containing gas is fed through the melt whereby the sulfur containing gas acts as a reagent to convert at least part of the alumina into aluminum sulfide and at least part of the melt is used in the second step. Further the invention relates to an apparatus for operating the method.

Owner:ALERIS ALUMINUM KOBLENZ GMBH

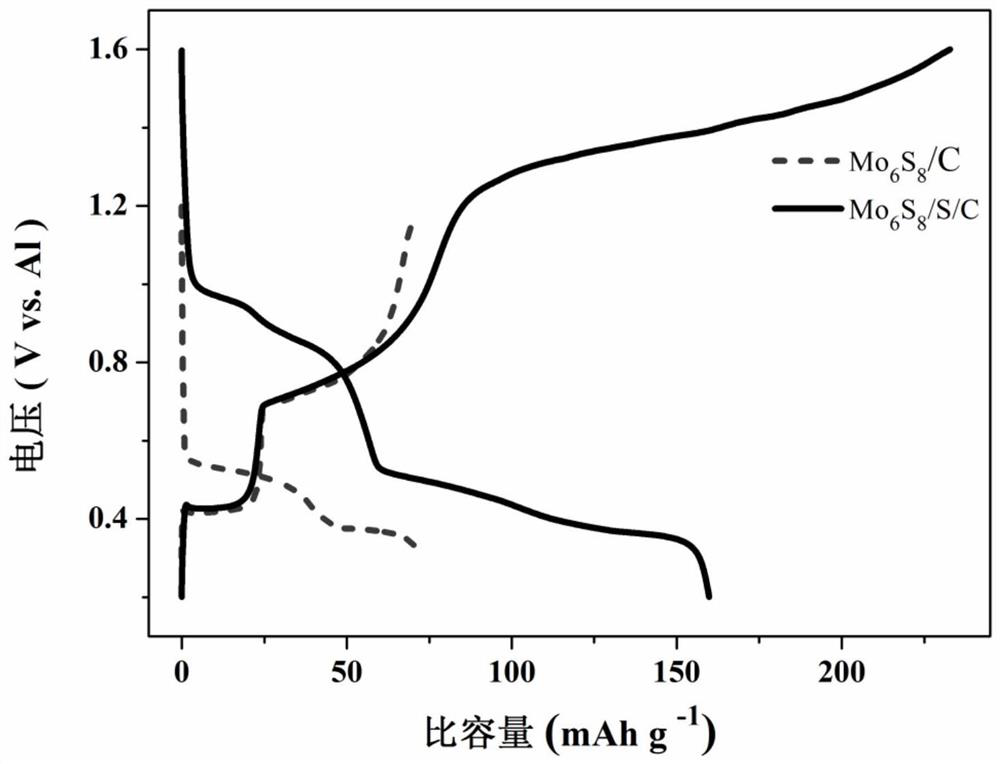

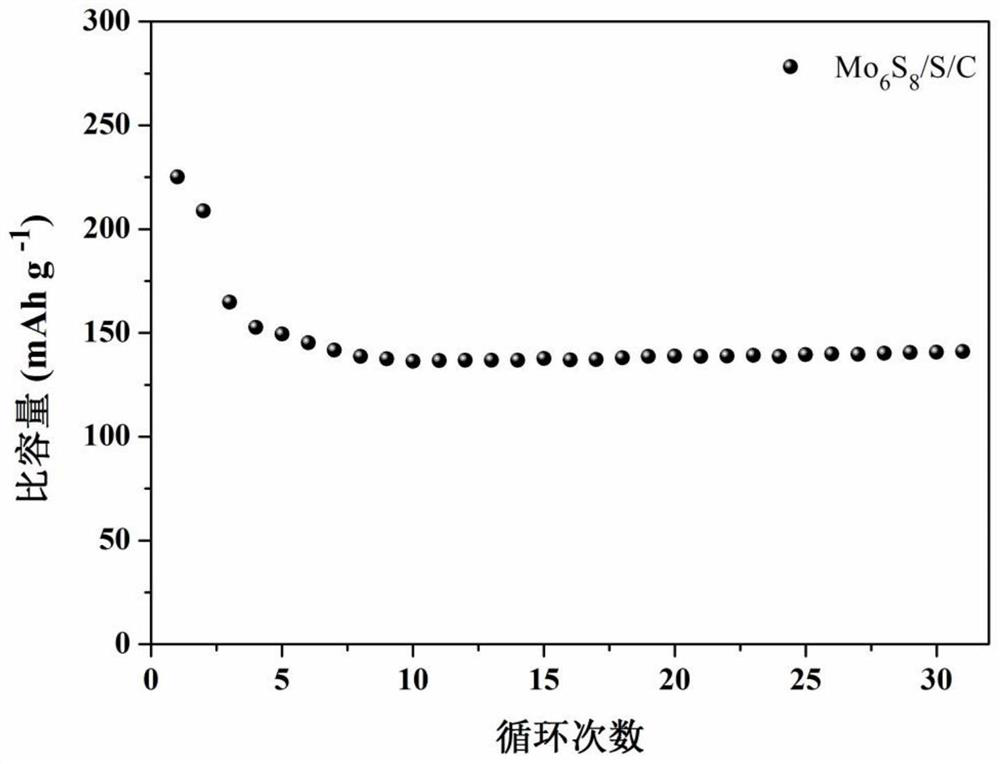

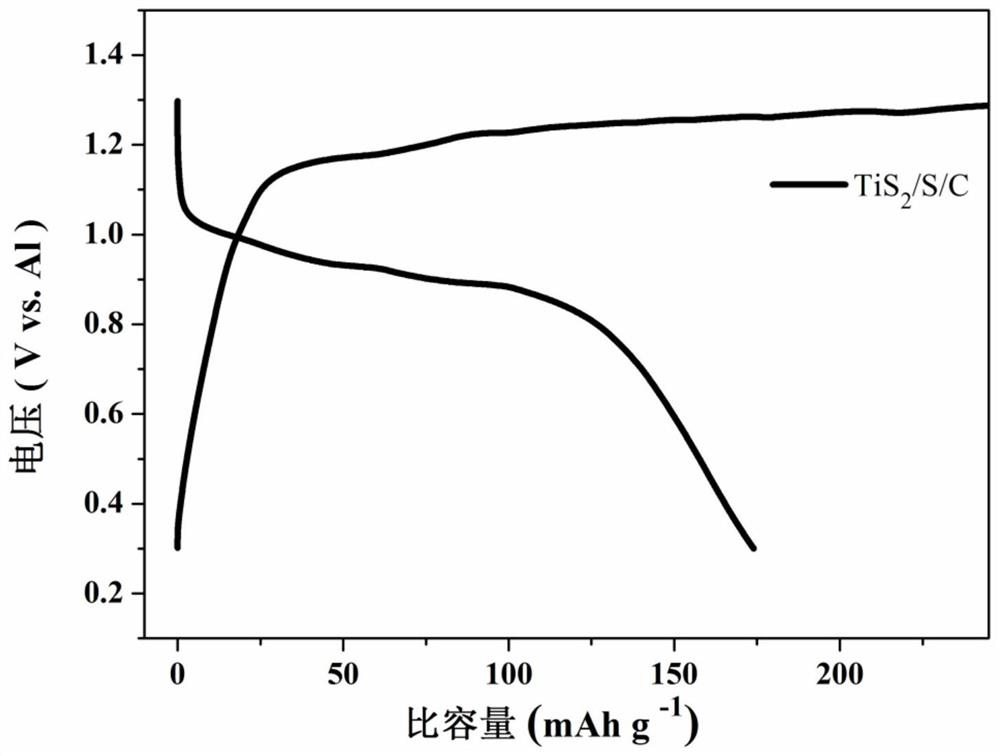

High-energy-density aluminum secondary battery and positive electrode material thereof, and preparation method ofpositive electrode material

PendingCN112038589AIncrease profitGood reversibilitySecondary cellsPositive electrodesElectrolytic agentElectrical battery

The invention discloses a high-energy-density aluminum secondary battery and a positive electrode material thereof, and a preparation method of the positive electrode material. The high-energy-densityaluminum secondary battery comprises a positive electrode containing a transition metal sulfide / sulfur composite positive electrode material, an electrolytic solution, a negative electrode and a diaphragm, wherein in the transition metal sulfide / sulfur composite positive electrode material, the transition metal sulfide is MxSy, M is a cation and comprises one or more solid solutions of Mo, Ti, Cu, Co, V, Fe, Cr, Ni, Mn, Zn, Sc, Nb, Mo, Zr, W, Re and Ta, x is greater than or equal to 0.01 and less than or equal to 9, y is greater than or equal to 1 and less than or equal to 8, x and y satisfycompound electric neutrality, the sulfur source comprises elemental sulfur and / or aluminum polysulfide Al2Sz, z is greater than or equal to 3 and less than or equal to 8, the mass percent of the transition metal sulfide is 5-95%, and the mass percent of the sulfur source is 5-95%.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Method for preparing sulfide and mixed product of sodium sulfide and lithium sulfate by manganese-containing waste liquid

InactiveCN102115040AEliminate pollutionEasy to operateCadmium sulfidesZinc sulfidesDistillationFractionation

The invention provides a method for preparing sulfide and mixed product of sodium sulfide and lithium sulfate by manganese-containing waste liquid, which comprises the steps of: leaching the manganese-containing waste liquid obtained by producing hydroquinone, and obtaining clear filtrate containing manganese sulfate, ammonium sulfate and sulfuric acid as well as a filter cake containing simple substance residue; leading the filter cake containing the simple substance residue to have reaction with the excess sulfuric acid, and obtaining solution containing calcium sulfate, magnesium sulfate, zinc sulfate, sodium sulfate, aluminum sulfate, cadmium sulfate and nickel sulfate; then, mixing the obtained solution and lithium sulfide solution for reaction, and obtaining mixed solution of the lithium sulfate and the sulfide containing calcium sulfide, magnesium sulfide, zinc sulfide, sodium sulfide, aluminium sulfide, cadmium sulfide and nickel sulfide; filtering the obtained mixed solution, and obtaining a mixed sulfide filter cake of the calcium sulfide, the magnesium sulfide, the zinc sulfide, the aluminium sulfide, the cadmium sulfide and the nickel sulfide as well as filtrate containing the sodium sulfide and the lithium sulfate; washing, drying, carrying out fractionation on the sulfide filter cake and grinding the sulfide filter cake, and obtaining the sulfide product; and finally, carrying out reduced pressure distillation and cooling crystallization on the filtrate containing the sodium sulfide and the lithium sulfate, and obtaining the mixed product of the sodium sulfide and the lithium sulfate.

Owner:王莉

Drilling waste drying agent as well as preparation method and use method thereof

InactiveCN106957140AImprove plasticityIncrease dosageWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningChlorideOperability

The invention discloses a drilling waste drying agent as well as a preparation method and a use method thereof. The drilling waste drying agent contains a first component and a second component which are respectively and independently packaged, wherein the weight ratio of the first component to the second component is (0.1-5) to (1-10); the first component contains magnesium sulfate, sulphamic acid, magnesium chloride and aluminium sulfide in a weight ratio of (60-80) to (0.5-5) to (10-30) to (5-15); and the second component is quick lime with a CaO content of higher than 70%. By utilizing the drilling waste drying agent, drilling waste can be processed into an incompact, dried, clean, neat and high-plasticity material with a wide terminal processing surface; and furthermore, the drilling waste drying agent is small in dosage, low in cost, strong in operability and suitable for the drilling waste with a liquid phase content of not higher than 97%, and a solid-liquid separation link in a preliminary discharging stage can be omitted.

Owner:BEIJING HUAXIA PIONEERING NEW MATERIAL

Synthesis method of aluminum sulfide

The invention discloses a synthesis method of aluminum sulfide, and belongs to the technical field of chemical synthesis. The method comprises the following steps: (1) weighing a certain amount of aluminum chloride and lithium sulfide; (2) uniformly mixing the above powders, transferring the uniformly mixed powder into a closed reactor and performing heating, and carrying out a constant temperature reaction for 1-100 h; and (3) separating a solid powder after the reaction to obtain aluminum sulfide. Compared with existing synthesis methods, the preparation method has simple synthesis process,mild reaction conditions, and relatively high purity of the synthesized aluminum sulfide.

Owner:ZHEJIANG UNIV OF TECH

Method of concurrently burning aluminate, bauxite and aluminium sulfide gel material for generating boiler

The invention relates to a method for producing gelatinization materials of aluminate, ferroaluminate and thioaluminate by using power generation boiler, which it is characterized by that 70-80% of raw coal, 10-18% of bauxite raw material and 8-15% of caustic lime are mixed, ground and homogenized, then the obtained mixed material is fed into powder-falling pipe, passed through air passage and fed into combustion chamber, after combustion the ash granules are passed through electrostatic precipitator to obtain the finished product, such as aluminate, ferroaluminate and thioaluminate gelatinization materials.

Owner:DENGFENG ELECTRICITY GRP

A kind of tungsten disulfide nanopowder material with aluminum sulfide shell and its preparation method

ActiveCN104310485BSimple preparation conditionsEasy to controlMaterial nanotechnologyAluminium sulfidesTungsten disulfideNanomaterials

The invention discloses a tungsten disulfide (WS2) nano powder material with an aluminum sulfide (Al2S3) shell, and a preparation method of the WS2 nano powder material, belonging to the technical field of preparation of nano materials. The nano powder material has a core-shell structure, wherein the inner core of the core-shell structure is WS2 nano-particles, and the shell of the core-shell structure is an Al2S3 layer; the inner core of the WS2 has the particle sizes of 10-100nm, and the Al2S3 shell layer is an amorphous Al2S3 layer and has the thickness of 1-10nm. According to the preparation method, tungsten powder and aluminum powder are pressed into a block according to a certain atomic percent by a plasma arc discharge method, and the block is taken as an anode material; graphite is taken as a cathode material; argon and hydrogen sulfide are taken as working gases; a certain distance is maintained between the cathode and the anode, and arc discharge is realized between the cathode and the anode, so that the WS2 nano powder material with the Al2S3 shell can be obtained. The preparation process is simple, the working procedure of aftertreatment is not needed, the cost is low, and industrial production can be easily realized.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Mordant for textiles

InactiveCN104264454AOvercome the defects of strong pertinence and single product directionFibre treatmentAluminum ammonium sulfateEngineering

The invention discloses a mordant for textiles. The mordant consists of the following substances in parts by weight: 30-38 parts of aluminum potassium sulfate dodecahydrate, 20-24 parts of cobaltous sulfate, 12-16 parts of copper sulfate, 8-12 parts of aluminum ammonium sulfate and 3-6 parts of aluminum sulfide. The mordant disclosed by the invention has the beneficial effects that the mordant for textiles overcomes the defects that the mordant is highly targeted and the product direction is single in the prior art by adjusting the composition and amount of the mordant, and the mordant for textiles can be suitable for various mordant dye and is good in market prospects.

Owner:WUXI DONGBEITANG HONGLIANG DYEING FACTORY

A kind of molybdenum disulfide nanopowder material with aluminum sulfide shell and preparation method thereof

ActiveCN104347876BSimple preparation conditionsEasy to controlCell electrodesMolybdenum sulfidesGraphiteCore shell

The invention discloses a molybdenum disulfide nanometer powder material with an aluminum sulfide housing and a preparation method of the molybdenum disulfide nanometer powder material, belonging to the technical field of preparation of nanometer materials. The nanometer powder material is of a core-shell structure, an MoS2 nanometer particle is used as an inner core, an Al2S3 layer is used as a housing; the particle size of the MoS2 inner core is 10nm-100nm, the Al2S3 housing layer is an amorphous Al2S3 layer and has a thickness of 1nm-10nm. According to the molybdenum disulfide nanometer powder material, by adopting a plasma arc discharge method, molybdenum powder and aluminum powder are briquetted into a block body according to a certain atomic percent to be used as an anode material, graphite is used as a cathode material, argon and hydrogen sulfide gases are introduced to be used as working gases, a certain distance is kept between a cathode and an anode, and arc discharge is achieved between the cathode and the anode, so that the MoS2 nanometer powder material with the Al2S3 housing is obtained. The preparation method is simple in preparation process, free from posttreatment procedure and low in cost; industrialized production is easily realized.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A kind of ferrous sulfide nano powder material with aluminum sulfide shell and preparation method thereof

InactiveCN104386765BSimple preparation conditionsEasy to controlMaterial nanotechnologyIron sulfidesNanometer particleNanomaterials

The invention discloses a ferrous sulfide (FeS) nanometer powdered material with an aluminium sulfide (Al2S3) casing and a preparation method thereof, and belongs to the technical field of preparing nanometer materials. The nanometer powdered material is in a core-shell structure, a kernel is an FeS nanometer particle, and the casing is an Al2S3 layer; the particle diameter of the FeS nanometer particle kernel is 10-100 nm, and the Al2S3 casing layer is an amorphous Al2S3 layer of which the thickness is 1-10 nm. According to the invention, a plasma arc discharge method is adopted, according to a certain atomic percent, ferrous powder and aluminium powder are pressed into a block which is used as an anode material, a graphite is used as a cathode material, an argon gas and a hydrogen sulfide gas are used as a work gas, a certain distance is kept between a cathode and an anode, and arc discharge is generated between the cathode and the anode, so that the FeS nanometer powdered material with the Al2S3 casing is obtained. The preparation process of the ferrous sulfide nanometer powdered material is simple, post-processing working procedures are avoided, and the cost is low, so that industrialized production is easy to realize.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

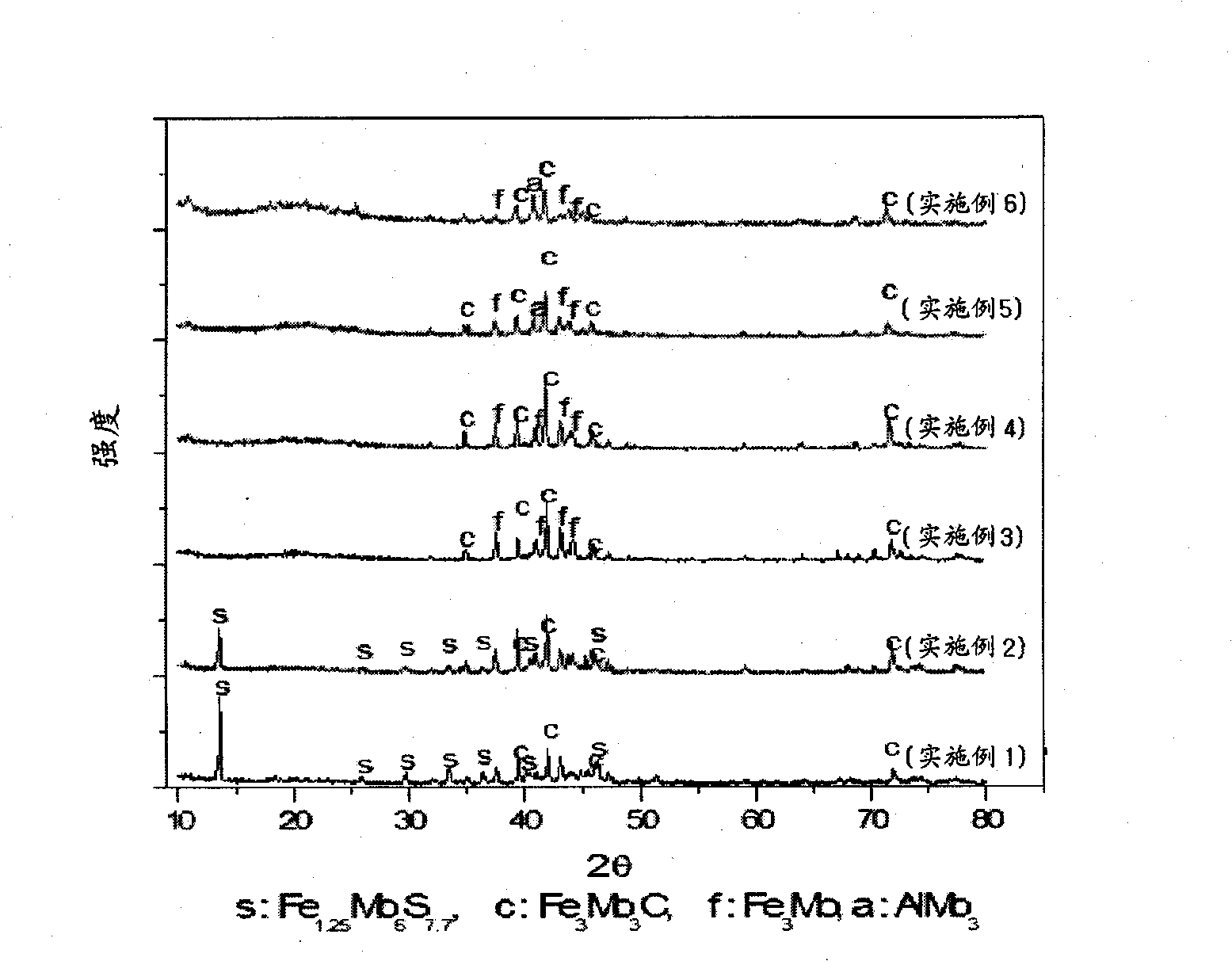

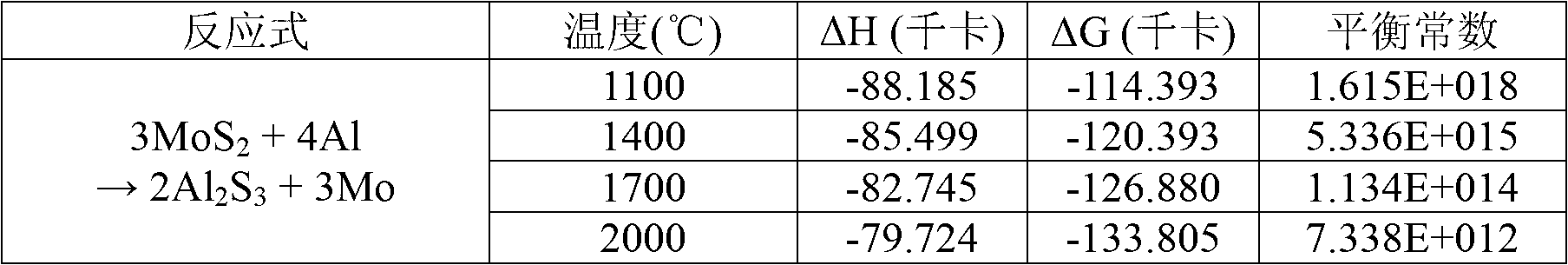

Method For Preparing Ferro Molybdenum From Molybdenite

The invention provides a method for producing ferromolybdenum from molybdenite concentrate, more specifically, it provides a method for producing ferromolybdenum with copper content below 0.5% from molybdenite with high copper content without separate removal Copper process method by placing molybdenite, metallic aluminum and metallic iron in a heating furnace and allowing them to react at high temperature, thereby producing ferromolybdenum in the lower part of said heating furnace, and in the upper part of said heating furnace The slag is formed using aluminum sulfide and iron sulfide as main components, and most of the copper (80%-95%) present in the molybdenite is placed in the slag layer. Exemplary embodiments may shorten the process and reduce consumption of a reducing agent (ie, aluminum) compared to a related art metallothermal reduction (thermite) method.

Owner:KOREA INST OF GEOSCI & MINERAL RESOURCES

Method for preparing sulfide and mixed product of sodium sulfide and ammonium sulfate by manganese-containing waste liquid

InactiveCN102115039AEliminate pollutionEasy to operateCadmium sulfidesZinc sulfidesAmmonium sulfideDistillation

The invention provides a method for preparing sulfide and mixed product of sodium sulfide and ammonium sulfate by manganese-containing waste liquid, which comprises the steps of: leaching the manganese-containing waste liquid obtained by producing hydroquinone, and obtaining clear filtrate containing manganese sulfate, the ammonium sulfate and sulfuric acid as well as a filter cake containing simple substance residue; leading the filter cake containing simple substance residue to have reaction with the excess sulfuric acid, and obtaining solution containing calcium sulfate, magnesium sulfate, zinc sulfate, sodium sulfate, aluminum sulfate, cadmium sulfate and nickel sulfate; then, mixing the obtained solution and ammonium sulfide solution for reaction, and obtaining mixed solution of the ammonium sulfate and the sulfide containing calcium sulfide, magnesium sulfide, zinc sulfide, sodium sulfide, aluminium sulfide, cadmium sulfide and nickel sulfide; filtering the obtained mixed solution, and obtaining a mixed sulfide filter cake of the calcium sulfide, the magnesium sulfide, the zinc sulfide, the aluminium sulfide, the cadmium sulfide and the nickel sulfide as well as filtrate containing the sodium sulfide and the ammonium sulfate; washing, drying and grinding the mixed sulfide filter cake, and obtaining the sulfide product; and finally, carrying out reduced pressure distillation and cooling crystallization on the filtrate containing the sodium sulfide and the ammonium sulfate, and obtaining the mixed product of the sodium sulfide and the ammonium sulfate.

Owner:王莉

Ball-milling synthetic method of aluminum sulfide

PendingCN110563013AAchieve continuous outputHigh single outputAluminium sulfidesChemical synthesisAluminium chloride

The invention discloses a ball-milling synthetic method of aluminum sulfide, and belongs to the technical field of chemical synthesis. The method comprises the following steps: (1) weighing a certainamount of aluminum chloride and lithium sulfide; (2) uniformly mixing the powder, putting the uniformly mixed powder into a ball-milling tank, and carrying out a mechanical ball-milling reaction; and(3) separating the reacted solid powder to obtain the aluminum sulfide. Compared with an existing synthetic method, the synthetic method provided by the invention has the advantages that heating conditions do not need to be provided by the outside, the preparation process is simple, the reaction conditions are mild, and the synthesized aluminum sulfide has higher purity.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com