High-energy-density aluminum secondary battery and positive electrode material thereof, and preparation method ofpositive electrode material

An aluminum secondary battery, high energy density technology, applied in the field of electrochemical energy storage, can solve the problems of poor cycle stability and low energy density, and achieve the effects of reducing dosage, high specific capacity and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The physical preparation method includes: weighing an appropriate amount of transition metal sulfide and a sulfur source, placing them in a ball mill tank, and performing sealed ball milling at 100-1000rmp for 1-48 hours to obtain a transition metal sulfide / sulfur composite positive electrode material; wherein the sulfur source is Elemental sulfur or aluminum polysulfide Al 2 S z ; where 3≤z≤8. Of course, carbon materials can also be added to form transition metal sulfide / sulfur / carbon composite cathode materials.

[0053] The chemical preparation method may include: weighing an appropriate amount of transition metal sulfide and adding it to an organic solution in which elemental sulfur is dissolved, heating and evaporating the organic solvent to precipitate elemental sulfur on the surface of the transition metal sulfide, and obtaining a transition metal sulfide / sulfur composite positive electrode material; , the organic solvent is one or more of tetrahydrofuran, o-xy...

Embodiment 1

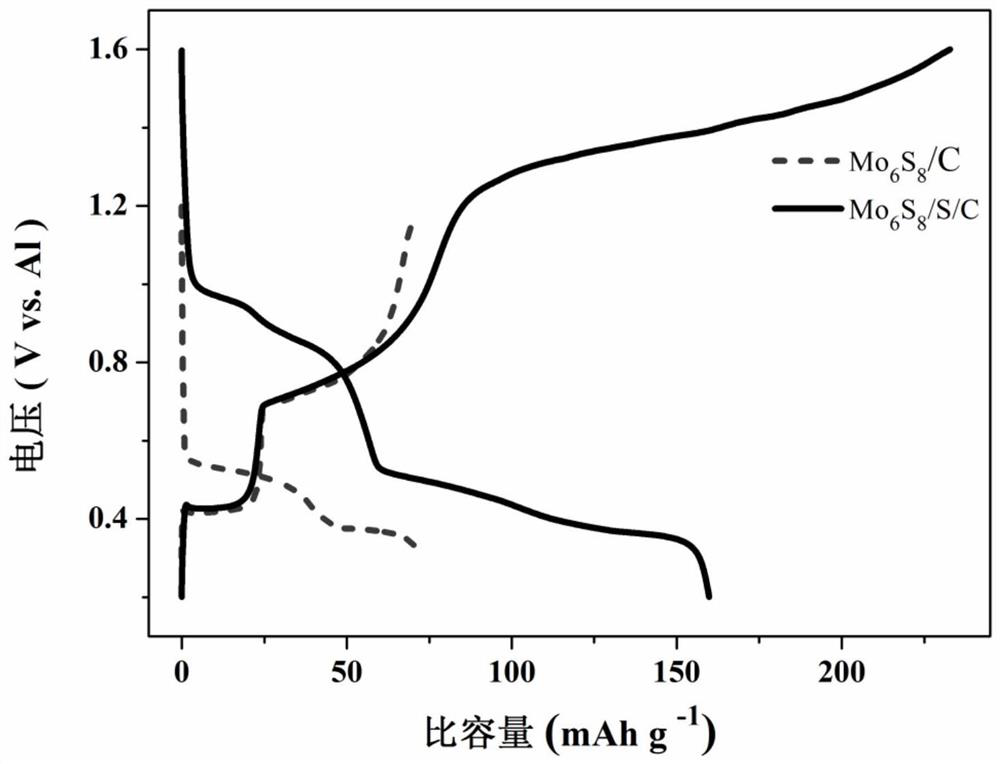

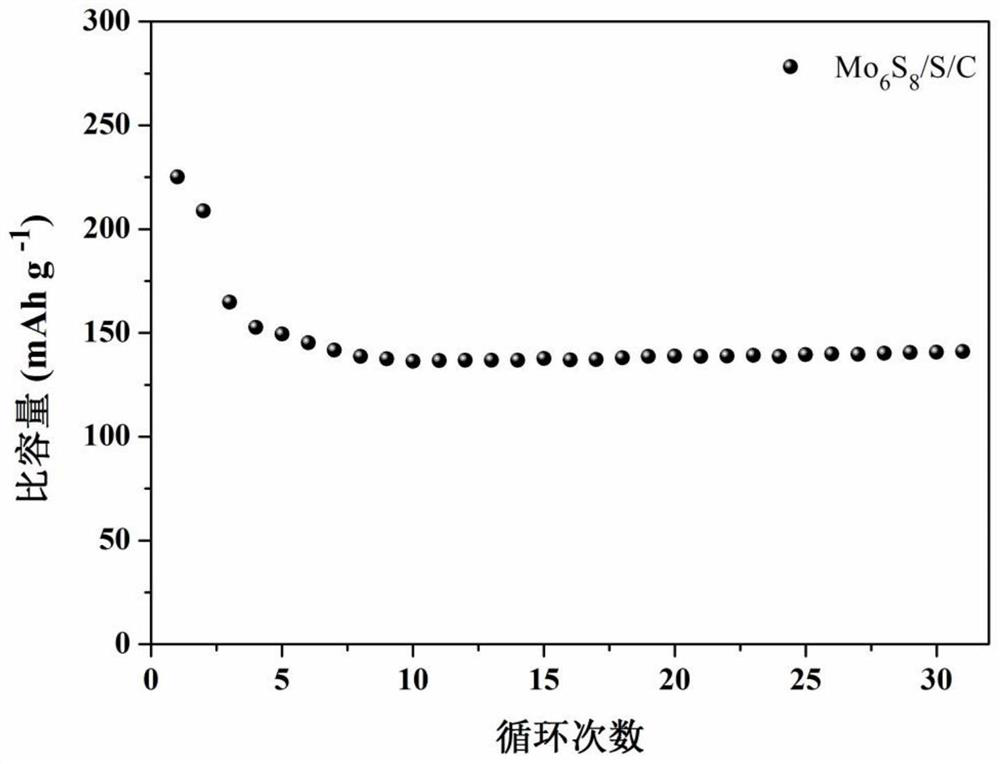

[0060] This embodiment provides a Mo 6 S 8 / S / C composite cathode material preparation and performance test.

[0061] (1) Add 0.8g Mo 6 S 8 Add 0.2g S element into the zirconia ball mill jar, and ball mill for 24 hours at a speed of 200rpm;

[0062] (2) Add 0.1g Ketjen black and 0.1g graphene in above-mentioned ball mill jar, continue ball milling 24 hours;

[0063] (3) Mix the material obtained in the above step (2) with the conductive agent Super P and the binder polytetrafluoroethylene in a mass ratio of 8:1:1, roll it on the positive electrode current collector, and vacuum at 55°C Dry for 10 hours to obtain the positive electrode;

[0064] (4) In a glove box filled with argon, with metal aluminum as the negative electrode and glass fiber GF / A as the diaphragm, AlCl 3 / [EMIm]Cl is the electrolyte solution and the positive electrode obtained in the above step (3) to assemble the aluminum secondary battery pouch battery.

[0065] (5) After the battery obtained in the a...

Embodiment 2

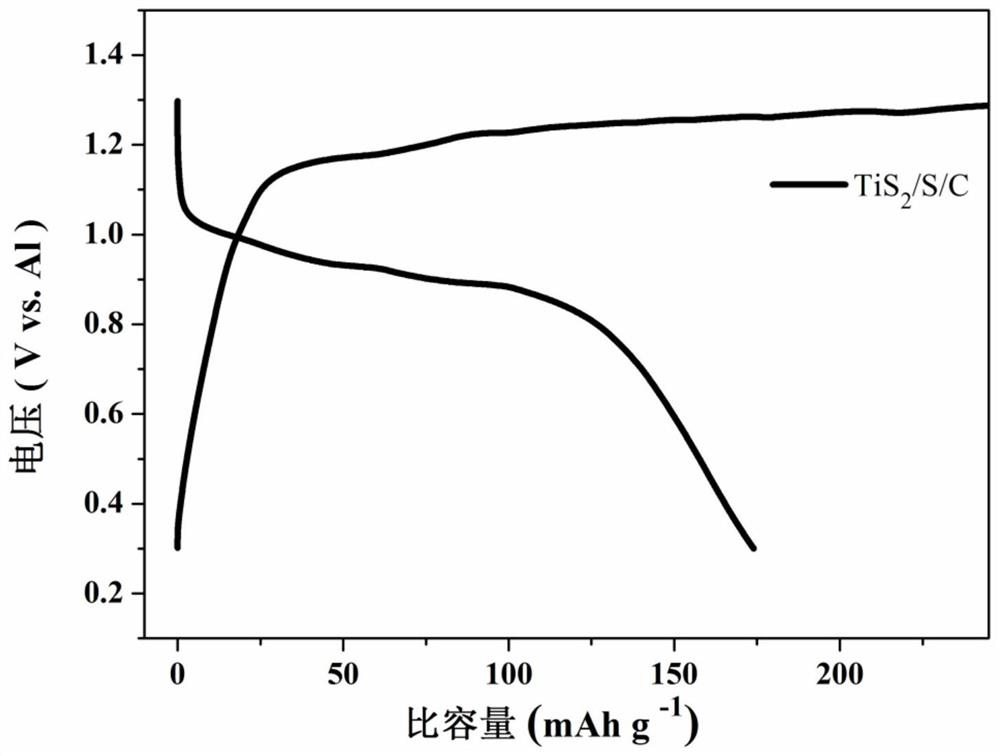

[0069] This embodiment provides a Cu 0.5 Mo 6 S 8 / S / C composite cathode material preparation and performance test.

[0070] (1) Add 0.2g Cu 0.5 Mo 6 S 8 , 0.8g S element, 2g Super P and 2g carbon nanotubes were added to the zirconia ball mill jar, and ball milled for 24 hours at a speed of 600rpm;

[0071] (2) Mix the material obtained in the above step (1) with the conductive agent Super P and the binder polytetrafluoroethylene in a mass ratio of 8:1:1, roll it on the positive electrode current collector, and vacuum at 55°C Dry for 10 hours to obtain the positive electrode;

[0072] (3) In a glove box filled with argon, with metal aluminum as the negative electrode, glass fiber GF / A as the diaphragm, AlCl 3 / [EMIm]Cl is an aluminum secondary battery pouch battery assembled with the positive electrode obtained in the above step (2) and the electrolyte.

[0073] (4) After the battery obtained in the above step (3) was left to stand for 3 hours, its electrochemical perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com