Drilling waste drying agent as well as preparation method and use method thereof

A technology of drilling waste and desiccant, which is applied in mining wastewater treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problems of increased cost of raw materials, transportation labor, etc., narrow selection, poor plasticity, etc., to achieve saving The effect of solid-liquid separation, wide terminal disposal surface and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] Specifically, the preparation method of the drilling waste drying agent may include the following steps:

[0023] Step A, according to the weight ratio of magnesium sulfate: sulfamic acid: magnesium chloride: aluminum sulfide=60~80:0.5~5:10~30:5~15, magnesium sulfate, sulfamic acid, magnesium chloride and aluminum sulfide are mixed together , and stirred at a speed of 20-100 revolutions per minute for 5-15 minutes to obtain the first component; quicklime with a CaO content greater than 70% is used as the second component. In practical applications, it is best to crush quicklime with a CaO content greater than 70% into quicklime powder with a fineness of 20-200 mesh as the second component, and it is best to grind magnesium sulfate, sulfamic acid, magnesium chloride and aluminum sulfide into fine Sieve powder with a 3mm sieve with a balance of no more than 1%, and then mix magnesium sulfate, sulfamic acid, magnesium chloride and aluminum sulfide together, which can impro...

Embodiment 1

[0034] A drilling waste drying agent comprises a first component and a second component packaged independently, and the weight ratio of the first component to the second component is 3:7.

[0035] Wherein, the first component is composed of magnesium sulfate, sulfamic acid, magnesium chloride and aluminum sulfide, and in terms of weight ratio, magnesium sulfate:sulfamic acid:magnesium chloride:aluminum sulfide=80:2:13:5. The second component is quicklime with a CaO content greater than 80% and a fineness of 120 mesh.

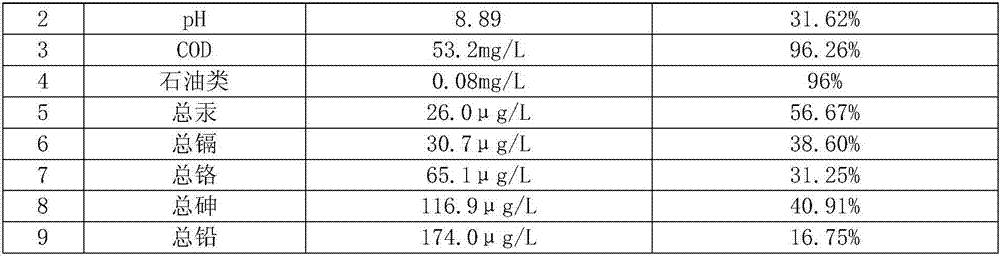

[0036] Specifically, using the drilling waste drying agent provided in Example 1 of the present invention to decontaminate and dry a certain drilling waste a, the specific method may include: using 3 weight parts per 100 weight parts of drilling waste a Parts of the first component and 7 parts by weight of the second component, the first component and the second component in the drilling waste drying agent were added to the drilling waste a, and then stirred and...

Embodiment 2

[0043] A drilling waste drying agent comprises a first component and a second component packaged independently, and the weight ratio of the first component to the second component is 3:7.

[0044] Wherein, the first component is composed of magnesium sulfate, sulfamic acid, magnesium chloride and aluminum sulfide, and in terms of weight ratio, magnesium sulfate:sulfamic acid:magnesium chloride:aluminum sulfide=80:5:10:5. The second component is quicklime with a CaO content greater than 80% and a fineness of 120 mesh.

[0045] Specifically, using the drilling waste drying agent provided in Example 2 of the present invention to decontaminate and dry a certain drilling waste b, the specific method may include: using 3 weight parts per 100 weight parts of drilling waste b Parts of the first component and 7 parts by weight of the second component, the first component and the second component in the drilling waste desiccant were added to the drilling waste b respectively, and then s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com