Tungsten disulfide nano powder material with aluminum sulfide shell, and preparation method of tungsten disulfide nano powder material

A tungsten disulfide, nano-powder technology, applied in aluminum sulfide, chemical instruments and methods, nanotechnology for materials and surface science, etc. simple conditional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

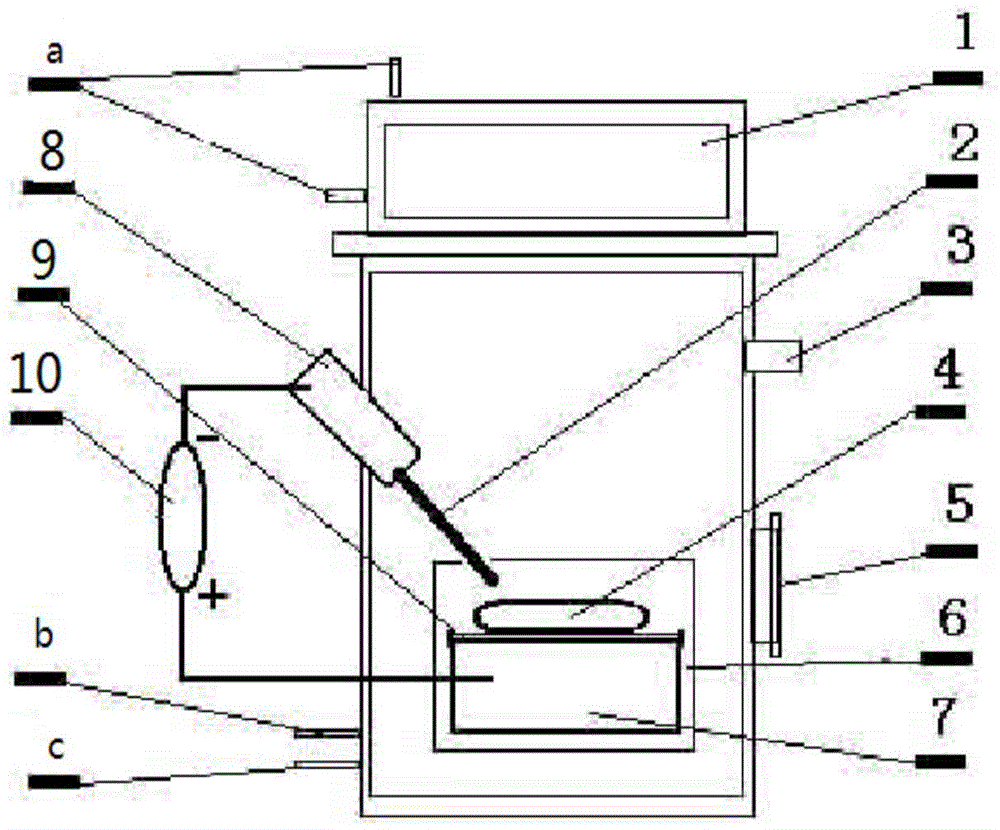

[0023] Will figure 1 The upper cover 1 of the device shown is opened, and graphite is used as the cathode 2 to fix it on the chuck 8. The composition of the consumed anode target 4 is a block made of pure tungsten powder and pure aluminum powder (atomic ratio 99:1). It is placed on the copper anode 7 passing through the cooling water, and there is a graphite crucible 9 between the copper anode passing through the cooling water and the target. A distance of 30 mm is maintained between the cathode graphite electrode and the anode tungsten aluminum powder block. Cover the upper cover 1 of the device, pass cooling water a, and after the whole working chamber is evacuated through the valve 3, argon gas b and hydrogen sulfide gas c are passed in, the partial pressure of argon gas is 0.5Mpa, and the partial pressure of hydrogen sulfide gas is 0.3Mpa , Connect the DC pulsating power supply 10 with a voltage of 40V. During the arc discharge process, adjust the working current and vol...

Embodiment 2

[0025] Will figure 1 The upper cover 1 of the device shown is opened, and graphite is used as the cathode 2 to fix it on the chuck 8. The composition of the consumed anode target 4 is a block made of pure tungsten powder and pure aluminum powder (atomic ratio 95:5). It is placed on the copper anode 7 passing through the cooling water, and there is a graphite crucible 9 between the copper anode passing through the cooling water and the target. Keep a distance of 2 mm between the cathode graphite electrode and the anode tungsten aluminum powder block. Cover the upper cover 1 of the device, pass cooling water a, and after the whole working chamber is evacuated through the valve 3, argon gas b and hydrogen sulfide gas c are passed in, the partial pressure of argon gas is 0.01Mpa, and the partial pressure of hydrogen sulfide gas is 0.01Mpa , and connect the DC pulse power supply 10 with a voltage of 10V. During the arc discharge process, adjust the working current and voltage to ...

Embodiment 3

[0027] Will figure 1 The upper cover 1 of the device shown is opened, and graphite is used as the cathode 2 to fix it on the chuck 8. The composition of the consumed anode target 4 is a block made of pure tungsten powder and pure aluminum powder (atomic ratio 98:2). It is placed on the copper anode 7 passing through the cooling water, and there is a graphite crucible 9 between the copper anode passing through the cooling water and the target. A distance of 10 mm is maintained between the cathode graphite electrode and the anode tungsten aluminum powder block. Cover the upper cover 1 of the device, pass cooling water a, and after the whole working chamber is evacuated through the valve 3, argon gas b and hydrogen sulfide gas c are passed in, the partial pressure of argon gas is 0.1Mpa, and the partial pressure of hydrogen sulfide gas is 0.1Mpa , Connect the DC pulsating power supply 10 with a voltage of 20V. During the arc discharge process, adjust the working current and vol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com