Method For Preparing Ferro Molybdenum From Molybdenite

A manufacturing method and technology of molybdenite, applied in the field of ferromolybdenum, can solve problems such as difficult to control the reaction and cannot obtain uniform products, and achieve the effects of promoting recovery, uniform production and continuous processing, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

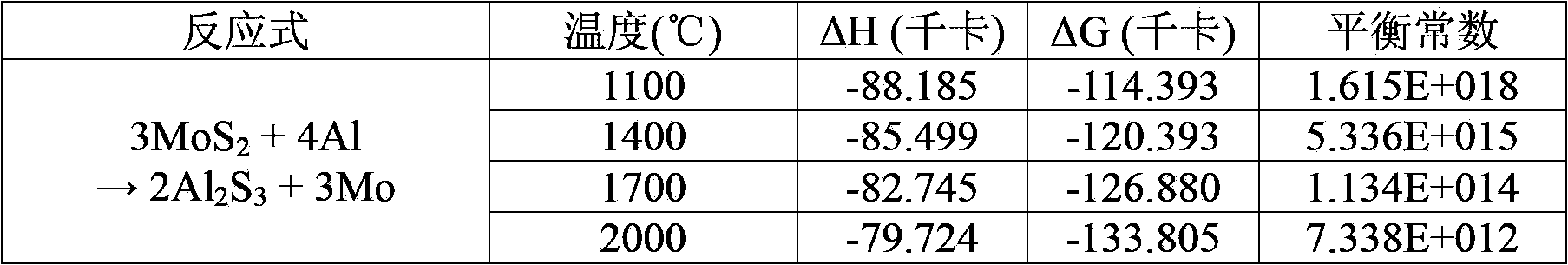

[0040] The sample mixture (i.e., 192 g of molybdenite, 56 g of iron powder and 32 g of aluminum powder) was spun at 140 rpm for 30 minutes at a filling rate of 50% in a 1-liter ceramic ball mill (diameter: 2 cm) and then separated from the balls. ) was used as a sample for reduction experiments.

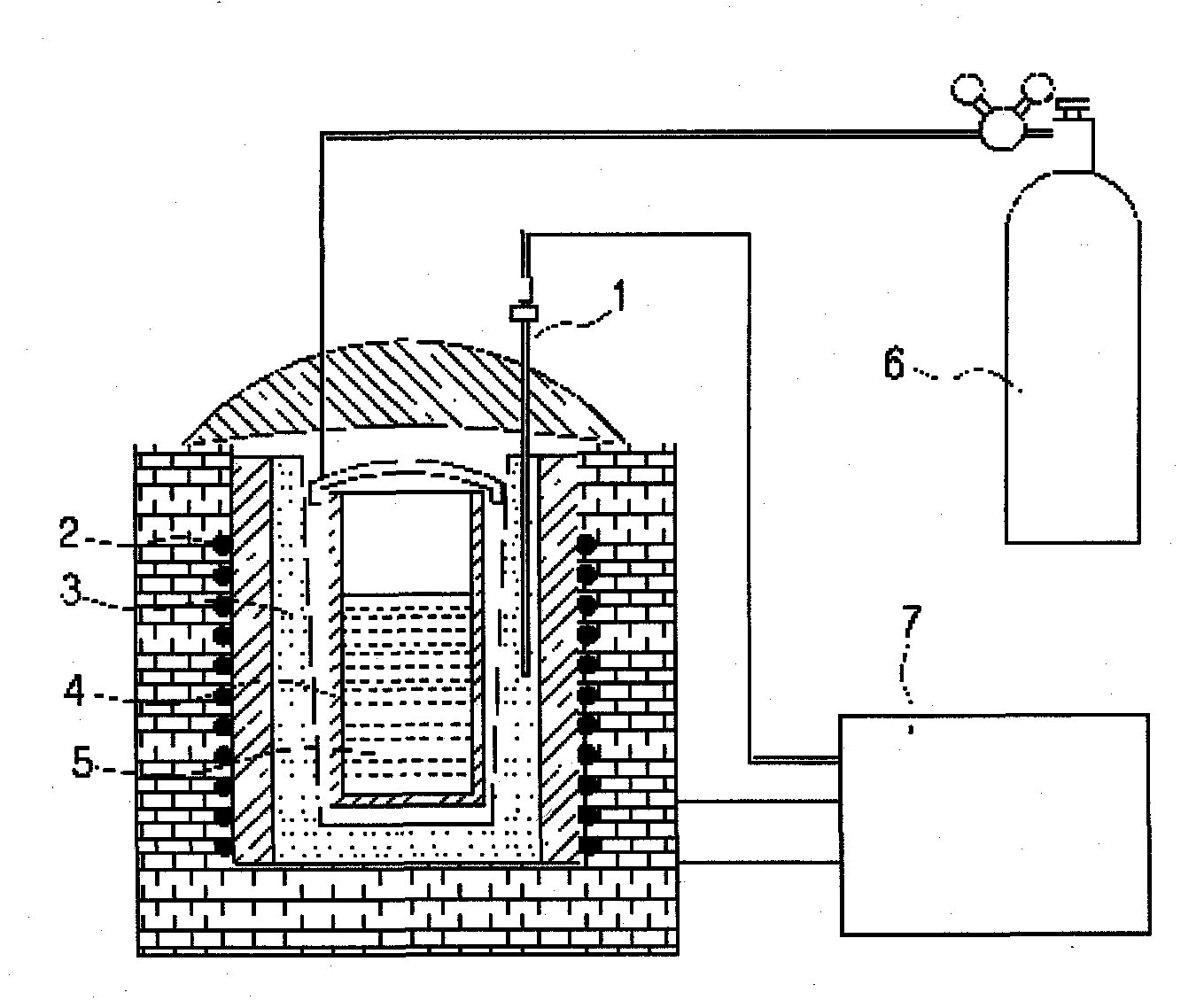

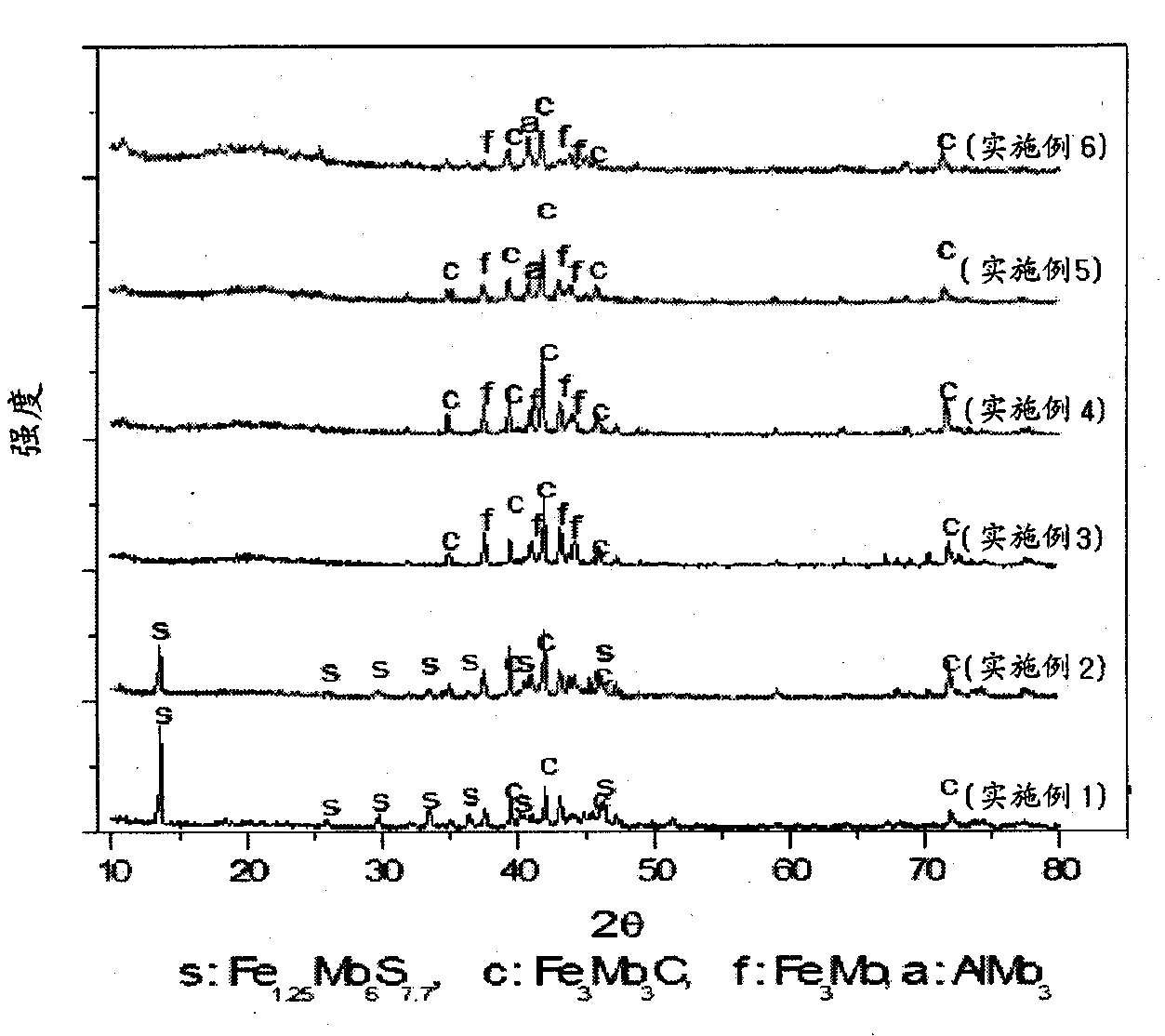

[0041] In the reduction reaction, an alumina crucible with a diameter of 8 cm and a height of 12 cm was used as a reactor. The mixed sample placed in the reactor was charged as figure 1 The graphite crucible of the apparatus is shown, and the experiment is carried out. Flow argon gas at a flow rate of 5 L / min for 20 minutes, start heating, and the temperature of the crucible reaches 1690° C. after 70 minutes. The reduction reaction was continued at this temperature for 10 minutes, and then the crucible was cooled for 12 hours at ambient temperature. In the experimental area, the reaction products were well separated into slag and ferromolybdenum. In this case, by figure 2 X-ray d...

Embodiment 2

[0043] In the mixing of samples, Example 2 is similar to Example 1, except that 36 g of aluminum powder is added.

Embodiment 3

[0045] In the mixing of samples, Example 3 is similar to Example 1, except that the added aluminum powder is 38g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com