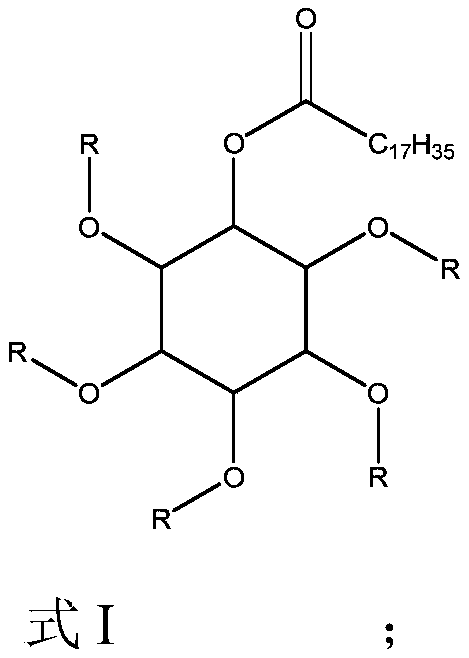

A kind of inositol fatty acid ester and its preparation method and application

A technology of application, II, applied in the field of inositol fatty acid ester and preparation thereof, can solve the problems of low output of dipentaerythritol hexastearate, high cost, unsatisfactory pentaerythritol tetrastearate and the like, and achieves safety Excellent, improve the injection molding performance, the effect of excellent internal and external lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

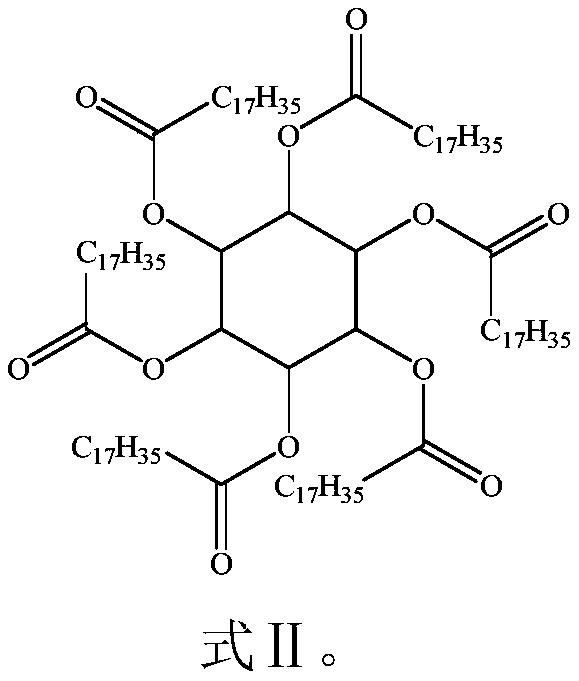

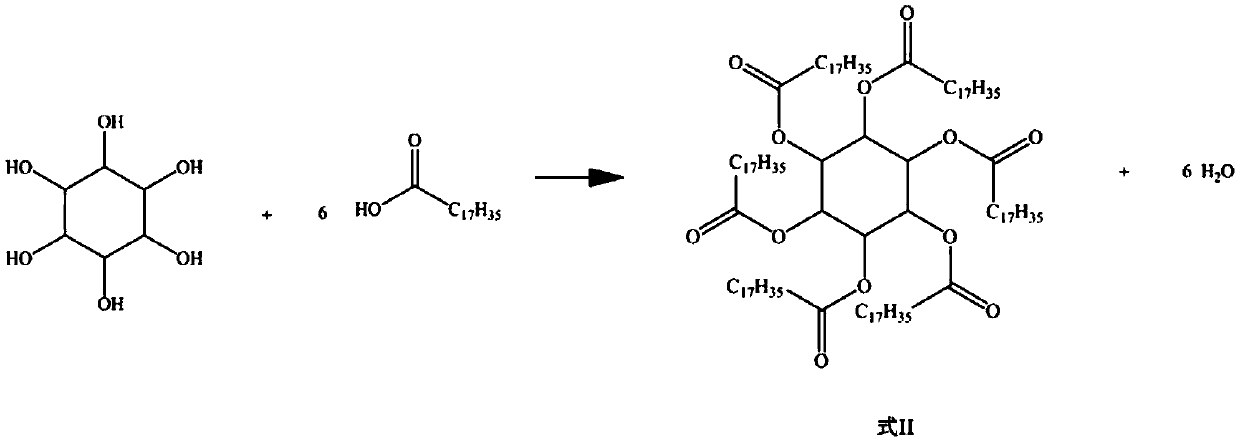

[0036] This embodiment discloses the preparation method of formula II compound inositol hexastearate of the present invention, and its reaction formula is

[0037]

[0038] The specific operation is as follows:

[0039] Take 30g of inositol, 284g of stearic acid, 1.6g of tin powder, and 60mL of xylene in a 500mL three-necked flask. The reaction device is equipped with a thermometer, electromagnetic stirring, oil bath, and reflux water separator.

[0040] Heat until reflux occurs, continuously separate the generated water until no water is formed, then cool until there is no reflux, add 3g activated clay and continue stirring for 1 hour, then filter under reduced pressure, recover xylene, cool, crush, and dry to obtain white 295 g of phytate in the form of waxy powder (yield>99%).

[0041] In the prior art, the industrial preparation process of higher fatty acid esters is generally carried out by polyhydric alcohol and higher fatty acid in the presence of a catalyst and a w...

Embodiment 2

[0044] This embodiment discloses the preparation of engineering plastics by using different plastic processing aids. The sources of raw materials and equipment are:

[0045] Raw material: bisphenol A polycarbonate Grade: 2805 Manufacturer: Bayer, Germany;

[0046] Inositol hexa-stearate: it is prepared by the method of Example 1;

[0047] Pentaerythritol tetrastearate: Corning LOXIOL P 861 / 3.5;

[0048] Ethylene bis stearamide: EBS; Hunan Changsha Hengchang Chemical Co., Ltd.;

[0049] Injection molding machine: China Haitian HT100;

[0050] Injection molding temperature: 270 (nozzle)-275-280-280-240 (rear section).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com