A transparent flame-retardant composite material capable of infrared penetration and its preparation method

A flame-retardant composite material and transparent technology, applied in the field of transparent flame-retardant composite materials and their preparation, can solve the problems of not having infrared rays passing through and laser engraving, and protection against unfavorable environment, and achieve strong scattering and blocking effects and pattern effects. Good, improve the effect of antioxidant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

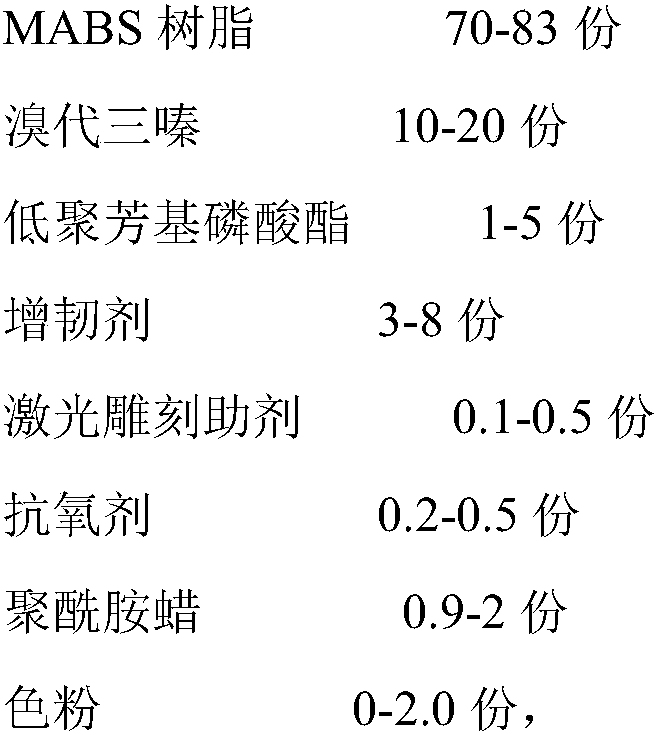

Method used

Image

Examples

Embodiment 1

[0071] With the MABS of 70.0 parts by weight, the bromotriazine of 18.0 parts by weight, the polyamide wax of 1.8 parts by weight; The oligomeric aryl phosphate of 4.0 parts by weight; The antioxidant of 0.2 parts by weight; The MBS of 6.0 parts by weight; 0.3 Laser engraving auxiliary agent in parts by weight; the above components are mixed uniformly at room temperature in a high-speed mixer, and then produced in a twin-screw extruder. Processing conditions: material mixing speed: 180 rpm; temperature in zone 1: 180°C, temperature in zone 2: 190°C, temperature in zone 3: 200°C, temperature in zone 4: 210°C, temperature in zone 5: 220°C, temperature in zone 6: Zone temperature: 220°C, Zone 7 temperature: 210°C, Zone 8 temperature: 210°C, Zone 9 temperature: 220°C, screw speed: 400 rpm, vacuum degree of the extruder is 0.08MPa, length of the extruder The diameter ratio is 25.

[0072] Wherein, the laser engraving auxiliary agent is a mixture of antimony and tin oxide, and the ...

Embodiment 2

[0074] With the MABS of 74.1 parts by weight, the bromotriazine of 16.0 parts by weight, the polyamide wax of 1.5 parts by weight; The oligomeric aryl phosphate of 3.0 parts by weight; The antioxidant of 0.3 parts by weight; The MBS of 5.0 parts by weight; 0.1 Laser engraving auxiliary agent in parts by weight; the above components are mixed uniformly at room temperature in a high-speed mixer, and then produced in a twin-screw extruder. Processing conditions: material mixing speed: 190 rpm; temperature in zone 1: 180°C, temperature in zone 2: 185°C, temperature in zone 3: 190°C, temperature in zone 4: 200°C, temperature in zone 5: 210°C, temperature in zone 6: Zone temperature: 220°C, Zone 7 temperature: 210°C, Zone 8 temperature: 210°C, Zone 9 temperature: 230°C, screw speed: 300 rpm, vacuum degree of the extruder is 0.09MPa, length of the extruder The diameter ratio is 30.

[0075] Wherein, the laser engraving auxiliary agent is a mixture of antimony and tin oxide, and the ...

Embodiment 3

[0077] With the MABS of 77.3 parts by weight, the bromotriazine of 14.0 parts by weight, the polyamide wax of 1.2 parts by weight; The oligomeric aryl phosphate of 3.0 parts by weight; The antioxidant of 0.4 parts by weight; The MBS of 4.0 parts by weight; 0.1 Laser engraving auxiliary agent in parts by weight; the above components are mixed uniformly at room temperature in a high-speed mixer, and then produced in a twin-screw extruder. Processing conditions: material mixing speed: 200 rpm; temperature in zone 1: 180°C, temperature in zone 2: 200°C, temperature in zone 3: 210°C, temperature in zone 4: 210°C, temperature in zone 5: 230°C, temperature in zone 6: Zone temperature: 220°C, Zone 7 temperature: 210°C, Zone 8 temperature: 210°C, Zone 9 temperature: 220°C, screw speed: 500 rpm, vacuum degree of the extruder is 0.1MPa, length of the extruder The diameter ratio is 35.

[0078] Wherein, the laser engraving auxiliary agent is a mixture of antimony and tin oxide, and the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com