High-voltage insulating epoxy resin composition for conductive column and preparation method thereof

An epoxy resin and high-voltage insulation technology, which is applied in the field of high-voltage insulation epoxy resin composition for conductive pillars and its preparation, can solve the problems of insufficient mold release, high requirements for flame retardancy, brittle and easy cracking, etc., and achieve high temperature resistance Not easy aging performance, excellent comprehensive performance, low moisture absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The raw materials for preparing the phosphorus-containing curing agent include p-aminophenol and phenylphosphoryl dichloride.

[0050] In a preferred embodiment, the molar ratio of the p-aminophenol and phenylphosphoryl dichloride is (2~3):1; more preferably, the molar ratio of the p-aminophenol and phenylphosphoryl dichloride is The molar ratio is 2.5:1.

[0051] The preparation process of the phosphorus-containing curing agent is: in a flask equipped with a stirrer, reflux condensation, thermometer, and nitrogen protection, add 0.25 mol of p-aminophenol, 100 mL of methyl isobutyl ketone, and 1.5 mL of triethylamine in sequence to heat Bring to 20~30℃, stir until the p-aminophenol is dissolved, pass nitrogen protection, heat up to 100~110℃, then add dropwise 40mL methyl isobutyl ketone solution with 0.1mol phenylphosphoryl dichloride, 1~2h drops After the addition is complete, react for 5-8h, stop heating, naturally cool to room temperature, filter, wash with dichlorometha...

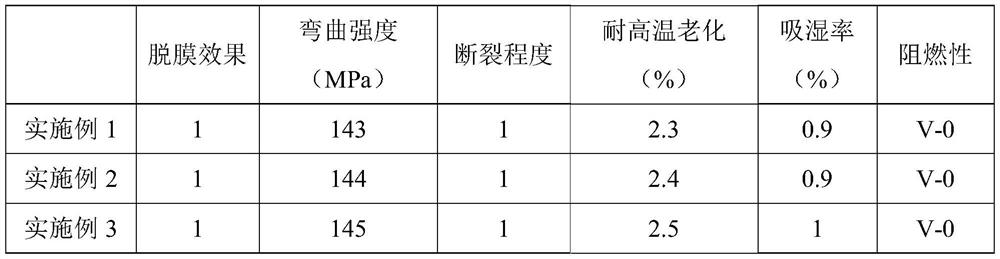

Embodiment 1

[0075] Embodiment 1 of the present invention provides a high-voltage insulating epoxy resin composition for conductive posts, which includes 90 parts epoxy resin, 60 parts curing agent, 0.05 parts accelerator, and 40 parts inorganic filler.

[0076] In parts by weight, the preparation raw material also includes 0.6 parts of a release agent.

[0077] The epoxy resin includes bisphenol A type epoxy resin, aliphatic epoxy resin and biphenyl type epoxy resin.

[0078] The bisphenol A epoxy resin was purchased from An Debao of Shanghai Huayi Resin Co., Ltd.

[0079] The aliphatic epoxy resin was purchased from ERL-4221 of Hubei Jusheng Technology Co., Ltd.

[0080] The biphenyl type epoxy resin was purchased from Mitsubishi YX4000HK of Shanghai Zhongsi Industrial Co., Ltd.

[0081] The mass ratio of the bisphenol A epoxy resin, aliphatic epoxy resin and biphenyl epoxy resin is 1:0.5:0.6.

[0082] The curing agent includes modified aromatic amine and modified aliphatic amine.

[0083] The modif...

Embodiment 2

[0098] Embodiment 2 of the present invention provides a high-voltage insulating epoxy resin composition for conductive columns, which includes 100 parts epoxy resin, 70 parts curing agent, 0.5 parts accelerator, and 80 parts inorganic filler.

[0099] In parts by weight, the preparation raw material also includes 0.9 parts of a release agent.

[0100] The epoxy resin includes bisphenol A type epoxy resin, aliphatic epoxy resin and biphenyl type epoxy resin.

[0101] The bisphenol A epoxy resin was purchased from An Debao of Shanghai Huayi Resin Co., Ltd.

[0102] The aliphatic epoxy resin was purchased from ERL-4221 of Hubei Jusheng Technology Co., Ltd.

[0103] The biphenyl type epoxy resin was purchased from Mitsubishi YX4000HK of Shanghai Zhongsi Industrial Co., Ltd.

[0104] The mass ratio of the bisphenol A epoxy resin, the aliphatic epoxy resin and the biphenyl epoxy resin is 1:0.7:0.8.

[0105] The curing agent includes modified aromatic amine and modified aliphatic amine.

[0106]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com