Residue oil hydrotreating method and system

A technology for hydrogenation and hydrogenation treatment of residual oil, which is applied in the field of hydrogenation, can solve the problems of waste and protection of reactor space, etc., and achieve the effects of increasing raw material processing capacity, simple switching, and slow deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

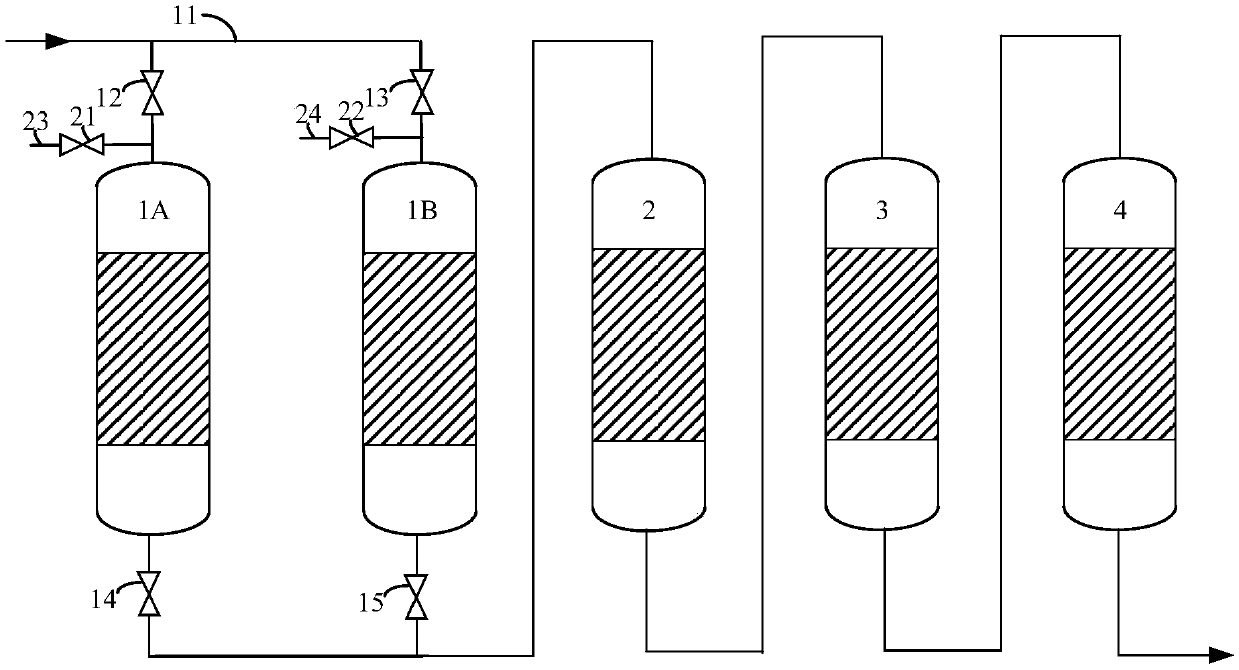

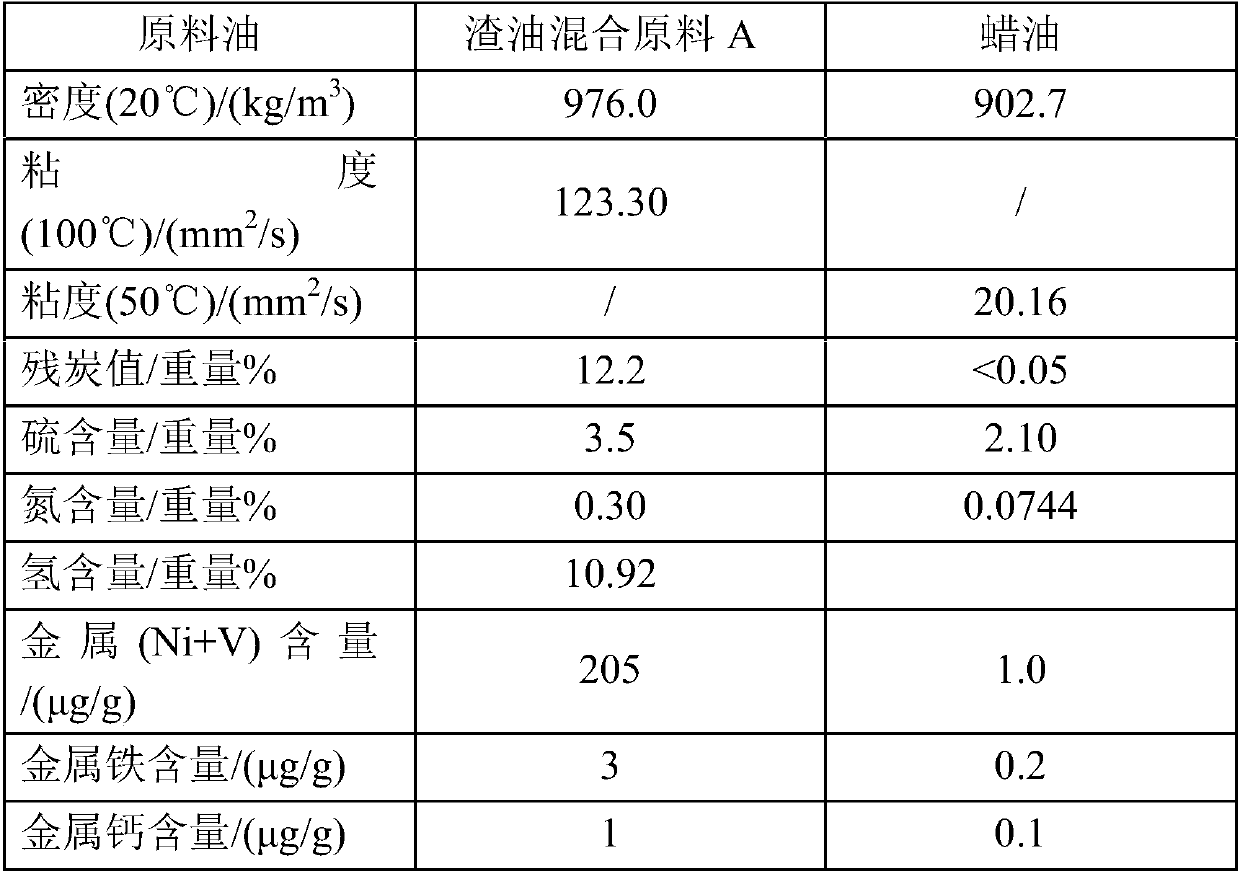

[0087] Such as figure 1 As shown, the residue mixed raw material A and hydrogen enter the first hydrogenation protection reactor 1A, and the wax oil raw material and hydrogen enter the second hydrogenation protection reactor 1B. The operating conditions of the fixed bed residue hydrogenation unit include: total volume space velocity 0.18h -1 (For residual oil mixed raw material), the feed amount of residual oil mixed raw material A is 75.6g / h, the hydrogen-oil volume ratio at the inlet of the first hydrogenation protection reactor 1A is 600:1, and the total volume space velocity is 0.12h -1 (to the wax oil raw material), the wax oil raw material feed rate is 50g / h, the second hydrogenation protection reactor 1B inlet hydrogen oil volume ratio 200:1, the first hydrogenation protection reactor 1A and the second hydrogenation protection reaction The hydrogen partial pressure at the inlet of device 1B is 15.0MPa.

[0088] During the whole operation cycle, the properties of the p...

Embodiment 2

[0091] Such as figure 1 As shown, the residue mixed raw material A and hydrogen enter the first hydrogenation protection reactor 1A, and the wax oil raw material and hydrogen enter the second hydrogenation protection reactor 1B. The operating conditions of the fixed bed residue hydrogenation unit include: total volume space velocity 0.22h -1 (For residual oil mixed raw material), the feed amount of residual oil mixed raw material A is 92.4g / h, the hydrogen-oil volume ratio at the inlet of the first hydrogenation protection reactor 1A is 650:1, and the total volume space velocity is 0.12h -1 (to the wax oil raw material), the wax oil raw material feed rate is 50g / h, the second hydrogenation protection reactor 1B inlet hydrogen oil volume ratio 150:1, the first hydrogenation protection reactor 1A and the second hydrogenation protection reaction The hydrogen partial pressure at the inlet of device 1B is 15.0MPa.

[0092] During the whole operation period, by adjusting the react...

Embodiment 3

[0099] Such as figure 1 As shown, the residue mixed raw material B and hydrogen enter the first hydrogenation protection reactor 1A, and the wax oil raw material and hydrogen enter the second hydrogenation protection reactor 1B. The operating conditions of the fixed bed residue hydrogenation unit include: total volume space velocity 0.20h -1 (for residual oil mixed raw material), the feed amount of residual oil mixed raw material A is 84g / h, the hydrogen-oil volume ratio at the inlet of the first hydrogenation protection reactor 1A is 600:1, and the total volume space velocity is 0.12h -1 (to the wax oil raw material), the wax oil raw material feed rate is 50g / h, the second hydrogenation protection reactor 1B inlet hydrogen oil volume ratio 200:1, the first hydrogenation protection reactor 1A and the second hydrogenation protection reaction The hydrogen partial pressure at the inlet of device 1B is 15.0MPa. When the device starts to operate, the pressure drop of the first hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com